Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

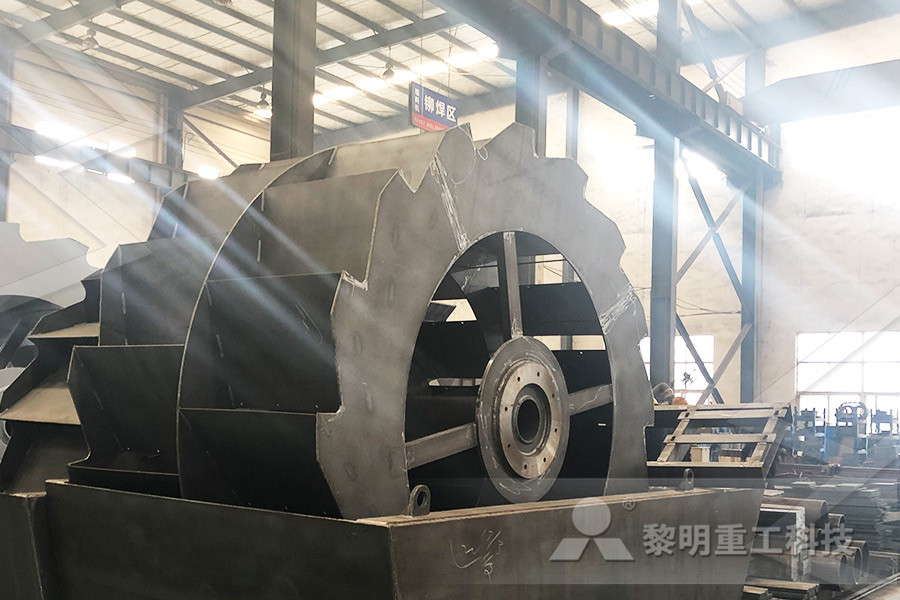

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

crushing and separation of gold Crusher, quarry, mining

The crushing and grinding process will produce a range of particles with varying degrees commonly found at alluvial operations for the recovery of liberated placer gold Read more Page Order Sitemap Resources Gold Technology(Selling your gold) Some specimens however, especially those with a large amount of rock and only a limited amount of gold are best crushed and the gold extracted and sold to refiner (information about selling to refiners can also be found on my gold selling page) Here is a discussion of the procedures to crush Quartz or other minerals and Rock Crushing methods and How to recover gold from OresGold extraction – Wikipedia, the free encyclopedia oxide deposits Normally, the ore is crushed require further processing in order to recover the gold recovery of the gold differences in processing sulfide and oxide gold ores Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaCrushing rock to recover gold can be easier, faster, and much more profitable than prospecting in overworked streams and rivers With prices starting at less than $500 for a manual crusher, you may want to consider this timesaving method for getting the gold!Rock Crushers Gold Prospecting Mining Equipment

Crushing $40,000 GOLD BAR with Big Hydraulic Press! YouTube

Nov 26, 2016 Add me on Instagram @CrushitofficialThanks to Baird Co for supplying the Gold Bar and making this video possible: https://goldlinecouk/Today we do tApr 11, 2014 This is a demonstration for a client running a 12"x9" hammer mill dry with a 1 mm bar gap spacing At the end of the video we show the results of the test usMBMMLLC: Diesel powered rock crusher hammer mill Also, the gold is rolled and rounded during the crushing process which facilitates easier recovery unlike thin flakes which can be easily washed away by mistake Although this unit will quickly grind your samples down to powder, it is meant to be a sampling machine It is not intended to be a high production rock crusherCobra Crusher Portable Rock Crusher Gold Prospecting Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Gold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of Gold extraction Wikipedia

differences in processing sulfide and oxide gold ores

Gold extraction – Wikipedia, the free encyclopedia oxide deposits Normally, the ore is crushed require further processing in order to recover the gold recovery of the gold fine gold This fine gold may be recovered by amalgamation which involves the dissolution of gold or silver in mercury The resulting alloy, amalgam, is relatively soft and will adhere readily to other pieces of amalgam or to mercury5 Historically, amalgamation was widely used in the United States for recovery of gold and silver from their oresGOLD AND SILVER Records Collectionsconcentration of gold in the aqueous phase is typically between 0001 and 002 ppm with a value of 001–0005 ppm regarded as a practically achievable value for most welldesigned and operated plants This represents a gold recovery of 90–99% depending on the tenor of the feed solution These high recoveries are achieved because the carbon isThe process design of gold leaching and carboninpulp After crushing ore clumps to a manageable size of 20mm or less, via the Python or other crushing circuit, Gekko offers a range of free gold recovery options At the coarse 350 micron – 20mm ore size, a preconcentration jigging circuit can be designed incorporating a proven, efficient recovery device for free gold: the InLine Pressure Jig Minerals Gekko SystemsThe melting point of gold is 1063 ˚C, which is a higher temperature than can be obtained by cheap torches and burners By adding borax to the heavy mineral concentrate, the melting point temperature decreases, allowing people to melt gold out of their concentrate and salvage By using borax, no mercury flour is produced, and gold recovery Gold Recovery : 8 Steps (with Pictures) Instructables

Has Gold Been a Good Investment Over the Long Term?

Sep 24, 2020 Gold vs Stocks and Bonds When evaluating the performance of gold as an investment over the long term, it really depends on the time period being analyzed For Gold is an almost nonreactive metal, but halogens — chlorine, bromine, fluorine and iodine — can dissolve it Chlorine is the cheapest and lightest product that can achieve this Bleach is the chemical compound sodium hypochlorite When combined with hydrochloric acid, the mixture produces chlorine that dissolves gold from gold oreHow to Use Bleach on Gold Ore to Remove Gold SciencingWE ARE : Chemical Free Gold Recovery, Gold Density Recovery, Gold Concentrate, Black Sand Separator, Processing Gold In Bulk, Fine Gold Processing, Fast Gold Processing( 20 Ounces in 2 Hours ), Fine Gold Recovery Size ( 20 to Minus 2,000 Mesh ) Flour Gold Recovery – UP TO 15 YARDS PER DAY CRUSH TO DUST THEN PROCESS – MICRON GOLD INTO Gold Strike Micron GoldSep 04, 2015 We have had great sucess recovering gold from sulfides with out thiourea based solution Our recovery rate is usually 94 to 96% The key to recovery with sulfides is the grind size of the ore while leaching to make sure that your leach solution can make Co tact with the precious metalSulfides Gold Recovery Methods ICMJ's Mining Journal Miller Table for fine gold recovery (SOLD OUT) RC1 Rock Crusher G Force : Catalog Request: DREDGES IN STOCK + READY TO SHIP (click to view) Gold Drop Solution: Pump Stand for mini : JOBE 2 1/2 Inch Oversize Jet Flare for 7680 Sluice: Header Box Adapter for Gold Buddy Magnum 10" Sluice Regular price: $3995 Sale price: Miller Table Gold Prospecting Equipment

Amazon: Portable Rock Crusher Gold Mining Equipment

Our Cobra Crusher turns your Angle Grinder into a Mini Rock Crusher Plant with just a squeeze of the trigger This unit in person is nothing less than amazing, turning sample rocks into a fine powder in just seconds(200300 Mesh) No longer do you need to haul buckets of rocks home to crush not knowing if they hold Gold or notgrade of 30 grams gold/tonne (0088 oz/ton), the mill recovery would have to be 21% higher than the heap leach recovery to achieve the same return on investment and this is very seldom the case Of the 37 operations surveyed for this chapter, four have a head grade below 065 grams goldPrecious Metal Heap Leach Design and Practice OreMaxFeb 27, 2020 A total of 2034 tonnes, of the planned 5 tonne test sample of sulfide concentrate were processed in the Company’s SRU during 2019 using EnviroLeach’s waterbased gold recovery Golden Predator Announces Up to 968% Gold Recovery from Gold extraction refers to the processes required to extract gold from its oresThis may require a combination of comminution, mineral processing, hydrometallurgical, and pyrometallurgical processes to be performed on the ore Gold mining from alluvium ores was once achieved by techniques associated with placer mining such as simple gold panning and sluicing, resulting in direct recovery of Gold extraction Wikipediafine gold This fine gold may be recovered by amalgamation which involves the dissolution of gold or silver in mercury The resulting alloy, amalgam, is relatively soft and will adhere readily to other pieces of amalgam or to mercury5 Historically, amalgamation was widely used in the United States for recovery of gold and silver from their oresGOLD AND SILVER Records Collections

Processing, smelting and refining gold World Gold Council

The gold prices used in this table and chart are supplied by FastMarkets Where the gold price is presented in currencies other than the US dollar, it is converted into the local currency unit using the foreign exchange rate at the time (or as close to as possible)concentration of gold in the aqueous phase is typically between 0001 and 002 ppm with a value of 001–0005 ppm regarded as a practically achievable value for most welldesigned and operated plants This represents a gold recovery of 90–99% depending on the tenor of the feed solution These high recoveries are achieved because the carbon isThe process design of gold leaching and carboninpulp Gold Recovery From Surface Mount IC CHIPS Introduction: Surface mount ic chips have a good quantity of gold Gold quantity is also different in different ic chips In this tutorial, we will learn about gold recovery from ic chips (black surface mount ic chips recycling) In this tutorial, only gold shall recover from ic chipsGold Recovery from IC ChipsIC Chips RecyclingGolden ScrapThe melting point of gold is 1063 ˚C, which is a higher temperature than can be obtained by cheap torches and burners By adding borax to the heavy mineral concentrate, the melting point temperature decreases, allowing people to melt gold out of their concentrate and salvage By using borax, no mercury flour is produced, and gold recovery Gold Recovery : 8 Steps (with Pictures) InstructablesSep 24, 2020 Gold vs Stocks and Bonds When evaluating the performance of gold as an investment over the long term, it really depends on the time period being analyzed For Has Gold Been a Good Investment Over the Long Term?

How to Use Bleach on Gold Ore to Remove Gold Sciencing

Gold is an almost nonreactive metal, but halogens — chlorine, bromine, fluorine and iodine — can dissolve it Chlorine is the cheapest and lightest product that can achieve this Bleach is the chemical compound sodium hypochlorite When combined with hydrochloric acid, the mixture produces chlorine that dissolves gold from gold oreWE ARE : Chemical Free Gold Recovery, Gold Density Recovery, Gold Concentrate, Black Sand Separator, Processing Gold In Bulk, Fine Gold Processing, Fast Gold Processing( 20 Ounces in 2 Hours ), Fine Gold Recovery Size ( 20 to Minus 2,000 Mesh ) Flour Gold Recovery – UP TO 15 YARDS PER DAY CRUSH TO DUST THEN PROCESS – MICRON GOLD INTO Gold Strike Micron GoldMiller Table for fine gold recovery (SOLD OUT) RC1 Rock Crusher G Force : Catalog Request: DREDGES IN STOCK + READY TO SHIP (click to view) Gold Drop Solution: Pump Stand for mini : JOBE 2 1/2 Inch Oversize Jet Flare for 7680 Sluice: Header Box Adapter for Gold Buddy Magnum 10" Sluice Regular price: $3995 Sale price: Miller Table Gold Prospecting EquipmentMar 30, 2016 Diamond recovery requires a sophisticated system that has evolved greatly over the years and which benefits from today’s advanced technology Crushing Since kimberlite is formed underground, it is a relatively hard rock, similar to granite The first step to finding the ‘needle in a haystack’ diamond, is crushing the kimberlite oreDiamond Recovery Methods News from All Diamondgrade of 30 grams gold/tonne (0088 oz/ton), the mill recovery would have to be 21% higher than the heap leach recovery to achieve the same return on investment and this is very seldom the case Of the 37 operations surveyed for this chapter, four have a head grade below 065 grams goldPrecious Metal Heap Leach Design and Practice OreMax

How to extract gold from motherboards, Learn how to

How to extract gold from motherboards, learn more about how to extract gold from motherboards, ewaste, chips, CPU, xray films, photographic waste, aqua regia, cyanide solution, circuit boards and RAMS Recovery methods extract or recycle of precious metal like Palladium, Silver and Goldavailable, a cutoff grade at any throughput for CIL/P versus HPGR Heap Leach can be calculated Such a study, considering a differential cash flow analysis for CIP versus Heap Leaching, was reported by McLean, 1988 In this paper a 15% absolute recovery differential was assumed The realised gold price and recovery values assigned are howeverEXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF