Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

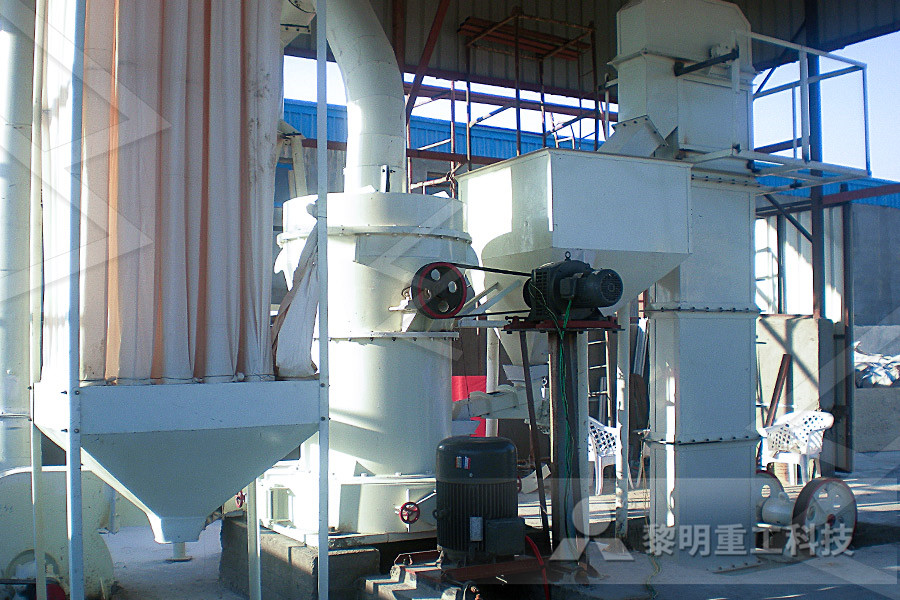

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Dry or Wet Magnetic Separator?Miningpedia

Dry magnetic separator is the mainstream magnetic separation equipment and it was also used for industrial weak magnetic separation as the earliest magnetic separation equipment It is suitable for dry and waterdeficient areas and mainly used to select bulk, coarsegrained ferromagnetism and finer particles of weak magnetic ore, which has a Lims separators are designed around the revolving magnetic drum with an internally stationary magnetic array They are available in several types for vast number of duties and could be seen as split into two categories, dry separation and wet separationLims magnetic separators Several types of magnetic separators have been used in magnetic medium recovery The first magnetic drum separators were electro magnetic types but the development of efficient wet permanent drum separators has resulted in nearly universal acceptance of permanent drums in new plants The basic construction of each drum is the sameWet Magnetic Drum Separator 911MetallurgistJun 01, 2020 Dry and wet laboratory magnetic separation were investigated for the different particle size range of the PCB dust For the dry separation, a drum electromagnetic separator with 140 mm wide and 120 mm diameter drum (product of Eriez Magnetics) was usedChemical conditioning for wet magnetic separation of The dry magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less It is also used for iron removal of coal, nonmetallic minerals, building materials and other materialsWhat is a dry magnetic separator? POWTECHINA

Eriez Wet Drum Separators

The Eriez Wet Drum Magnetic Separators is engineered and fabricated to provide reliable operation in demanding applications The separator is designed for the continuous treatment of coarse milled ore providing a high level of availability The tank and drum are fabricated from heavy gauge stainless steel with wear plate in impact areasEriez Dry High Intensity Rare Earth Roll Magnetic Separator With the ever increasing demand for highpurity feedstocks used in manufacturing, Eriez offers its Dry High Intensity Rare Earth Roll Magnetic Separators These provide maximum efficiency in the separation of weak magnetic particles for product purification applicationsEriez Dry High Intensity Magnetic SeparationFor many years, wet magnetic drum separator magnet rating has been on the basis of a specified gauss reading at 2″ from the drum face The gauss reading is an average of readings taken at the centerline of each pole and the center of the magnet gap measured 2 inches from the drum surfaceMagnetic Separators 911MetallurgistDry magnetic separators, including both drum and roll types, generally offer far more precise separations than wet magnetic separators Dry magnetic separation is more controllable since the separation medium is air rather than water Separating particles from one another is naturally easier without having to fight drag forces created by waterA discussion of magnetic separation techniques for Dry lowintensity magnetic separator There are two types of dry lowintensity magnetic separator 1 Use suspended magnets, magnetic pulleys and plate, and grate magnets to remove iron and strong magnetic impurities 2 The magnetic drum is mainly used to concentrate the valuable components of strong magnetism Wet lowintensity magnetic separatorsMagnetic Separator Mineral Processing

Wet Drum Magnetic Separator JXSC Machine

【Application of magnetic separation】 Wet drum magnetic separation is suitable for wet magnetic separation of magnetite, pyrrhotite, roasting ore, ilmenite and other materials with a particle size of 3mm or less It is also used for iron removal of coal, nonmetallic minerals, building materials, etc 1 Simple structure 2 Big capacity 3Dry magnetic separation Vs wet Depending on the nature of the environment in which the particles are divided into magnetic and nonmagnetic fractions, we have t Dry magnetic separation (air environment) Wet magnetic separation (water environment) Dry magnetic separation is usually used for the separation of 1100 mm size oreMagnetic Separation For Ore Dressing and Metallurgy The wet magnetic separator has a tank to accommodate the slurry to maintain the fluidity of the material, and the pump is usually transported by a slurry pump Mineral size Dry magnetic separation function for bulk, coarse particle separation, but also fine mineral separation, while wet magnetic separator can not sort large bulk minerals, most How Many Types of Magnetic Separators? JXSC MachineThe magnetic fraction to be separated must be ferromagnetic and dry, and the feed size should be –1" (–25 mm) Selectivity increases when the products to be separated are within four Tyler mesh sizes moisture adversely affects separator performance but can be tolerated as long as the feed is Dry Low Intensity Magnetic Separators (DLIMS) Eriez Lab Nov 09, 2020 Magnetic separation is an indispensable part of magnetic separation, and the dry magnetic separator can be selected under the condition of (PDF) Variables and Applications on Dry Magnetic Separator

Eriez Wet Drum Separators

The Eriez Wet Drum Magnetic Separators is engineered and fabricated to provide reliable operation in demanding applications The separator is designed for the continuous treatment of coarse milled ore providing a high level of availability The tank and drum are fabricated from heavy gauge stainless steel with wear plate in impact areasEriez Dry High Intensity Rare Earth Roll Magnetic Separator With the ever increasing demand for highpurity feedstocks used in manufacturing, Eriez offers its Dry High Intensity Rare Earth Roll Magnetic Separators These provide maximum efficiency in the separation of weak magnetic particles for product purification applicationsEriez Dry High Intensity Magnetic SeparationDry magnetic separators, including both drum and roll types, generally offer far more precise separations than wet magnetic separators Dry magnetic separation is more controllable since the separation medium is air rather than water Separating particles from one another is naturally easier without having to fight drag forces created by waterA discussion of magnetic separation techniques for “Magnetic Separation Technology is the most important technology for any recycling industry” Magnetic Separation is the process, in which the “magnetically caused material is detached easily” by using a magnetic force From last many years, magnetic separators are used for various separation process in recycling industry like Glass recycling, Scrap material, Pet flakes, Plastic Magnetic Separation Technology For A Recycling IndustryWet High Intensity Magnetic Separators (WHIMS) Separate ferromagnetic and paramagnetic particles and tramp metals with the world’s most efficient solutions Applications include heavy minerals, ilmenite, manganese and iron ore (haematite) beneficiation; PGM upgrading as well as Wet High Intensity Magnetic Separators Multotec

Magnetic Separator an overview ScienceDirect Topics

As discussed in Section 1341, flocculation of magnetic particles is a concern in magnetic separators, especially with dry separators processing fine material If the ore can be fed through the field in a monolayer, this effect is much less serious, but, of course, the capacity of Benefits of Multotec Dry Magnetic Drum Separators: Dry Magnetic Drum Separators: Dry Drum Magnetic Separators facilitate a more efficient milling and processing operation, achieved through an initial upgrade of the desired feed material Multotec’s Dry Drum Magnetic Separators are ideal for rougher or primary beneficiation applicationsMagnetic Drum Separators MultotecThe wet magnetic drum separators are available in two major magnetic configurations: WLIMS(Wet Low Intensity Magnetic Separator) Ceramic magnets are the basic building blocks of the magnetic circuit of these separators WMIMS(Wet Medium Intensity Magnetic Separator) Rare Earth Magnets (NdFeB) constitute the basic building block of the WET MAGNETIC DRUM SEPARATOR – MalvernDry magnetic separation Vs wet Depending on the nature of the environment in which the particles are divided into magnetic and nonmagnetic fractions, we have t Dry magnetic separation (air environment) Wet magnetic separation (water environment) Dry magnetic separation is usually used for the separation Magnetic Separation For Ore Dressing and Metallurgy The wet magnetic separator has a tank to accommodate the slurry to maintain the fluidity of the material, and the pump is usually transported by a slurry pump Mineral size Dry magnetic separation function for bulk, coarse particle separation, but also fine mineral separation, while wet magnetic separator How Many Types of Magnetic Separators? JXSC Machine

Eriez Dry High Intensity Magnetic Separation

Eriez Dry High Intensity Rare Earth Roll Magnetic Separator With the ever increasing demand for highpurity feedstocks used in manufacturing, Eriez offers its Dry High Intensity Rare Earth Roll Magnetic Separators These provide maximum efficiency in the separation of weak magnetic The magnetic fraction to be separated must be ferromagnetic and dry, and the feed size should be –1" (–25 mm) Selectivity increases when the products to be separated are within four Tyler mesh sizes moisture adversely affects separator Dry Low Intensity Magnetic Separators (DLIMS) Eriez Lab Examples of the wet separators are the Eriez LIMS manufactured by Eriez and Multotec LIMS manufactured by Multotec They are commonly used to recover / reject magnetite from HMC ahead of high intensity wet or dry magnetic separation For the wet Magnetic Separation ttms999As discussed in Section 1341, flocculation of magnetic particles is a concern in magnetic separators, especially with dry separators processing fine material If the ore can be fed through the field in a Magnetic Separator an overview ScienceDirect Topics【Advantages】 1, This patented product is a kind of upgrading equipment based on conventional magnetic roller or conventional dry separator When it is working, the magnetic minerals will take rapid magnetic reversal and magnetic agitation, which will significantly reduce the number of nonmagnetic (weak magnetic) minerals in the magnetic Dry Magnetic Separator psycarecoza

Magnetic separation: Magnetic sorting technology with

Magnetic separation technology for traditional as well as a growing number of new applications – with over 125 years of experience The diverse STEINERT product range with many different magnetic separators and eddy current separators Dry magnetic separators, including both drum and roll types, generally offer far more precise separations than wet magnetic separators Dry magnetic separation is more controllable since the separation A discussion of magnetic separation techniques for “Magnetic Separation Technology is the most important technology for any recycling industry” Magnetic Separation is the process, in which the “magnetically caused material is detached easily” by using a magnetic force From last many years, magnetic separators are used for various separation Magnetic Separation Technology For A Recycling IndustryFor more than 80 years, SG Frantz® has been manufacturing Magnetic Separators for the removal of fine magnetic particles from liquids, slurries, gases, dry granular materials and powders By SG Frantz – 80 Years of Magnetic Separation ExcellenceMagnetic separation is based on direct physical separation of minerals in a magnetic field Related to magnetic properties, minerals can be divided into three basic groups: ferromagnetic, paramagnetic and diamagnetic Due to magnetic susceptibility differences in particles the separation is accomplished wet or dry, at various magnetic {The wet high intensity magnetic separation of magnesite

Avalon Bitcoin Miner Machine Wet dry Drum Magnetic Separator

Wet drum magnetic separators are used in the fine grain range from µm 0 mm – 6 mm to separate magnetic particles from process liquids, sludges or emulsions Their strong magnetic fields enable the efficient separation of magnetite or ferrosilicon from the wet Wet Magnetic separator is the highest efficiency for strong magnetism minerals separation and can provide protection to downstream process machines by separating ferrous debris According to different materials,three styles of drum magnetic separator drum magnetic separator,wet magnetic separatorMag Spring®