Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

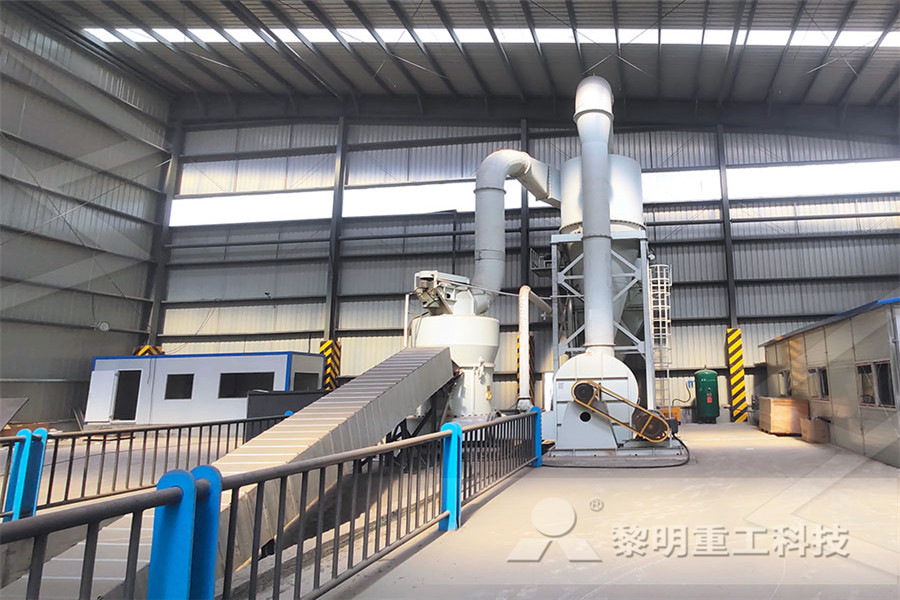

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

11 Chain Pull Calculations John King Chains

(29) Chain and Material Elevated Vertically Note for (21) (25) Chain and material sliding in scraper and drag link conveyors to calculate chain pull additional parameters must be included F2 = Coefficiency of Friction between material to be moved and sides of trough L = portion of loaded conveyorSuperior's conveyor calculator provides the minimum horsepower required at the headshaft of a conveyorConveyor Horsepower Calculator Superior Industries Plastic Chain Conveyor Calculator: Minimum Between Rail Width on Curves Determine the minimum width of your curved conveyor Get Quote Live Roller Conveyors; If you have guardrails on your curve and the package being conveyed is too long, the package may become jammed in the curve if the curve is not wide enough Conveyor Curve Calculator Configure Curved Roller ConveyorsMaximum chain tension (T), calculated by the above formula (s) is for two strand of chain 7) Determination of model (chain size) Multiply the maximum chain tension (T) by the chain speed coefficient (K) listed in table 6 and verify with the following formula: T * Industrial Conveyor CorporationConveyor Chain Pull Calculation Software 2 452 035 Normal friction factor for average conditions over 20 degree F to move empty belt 1000 Kg or L Use this calculator to calculate the force, torque and power required from a conveyor to move a load at an angleConveyor Chain Pull Calculation Software

Chain conveyor calculations Bechtel GmbH

As a specialist in the field of conveyor technology, Bechtel can also help you with design questions of chain conveyors Download PDF Calculations We provide you with the basic calculations for the determination of chain speed, capacity per hour, weight of the material to be conveyed, as well as the calculation of the required powerto design/calculate your conveyor Chain pull calculation – straight running conveyors 64 ENGINEERING MANUAL EM Edition 14 • 06/2006 Chain pull calculation elevators Power absorption 66 ENGINEERING MANUAL Chain/belt Lubrication Wearstrip material material Stainless steel, UHMWPE NoluS Return Extra Csteel PA roller SSE Dry 050 0 CALCULATION Required data for chain calculationThe design chain pull is calculated using the actual drive and motor selected and doing so will ensure the chain does not fail under upset conditions Additional factors for design chain pull include the Speed Factor and Service Conditions The design chain pull can be calculated using the following formula P = Design Chain Pull (LB)DragonFlite Drag Conveyor Horsepower Calculation Selecting the right chain for a given application is essential to obtain long service life This guide has been developed for use with Renold conveyor chain to help in specifying the right chain and lubrication for your conveyor system The significance of the Renold conveyor chain design is emphasised, followed by guidance on selection procedureConveyor Chain Designer Guide Renold Plastic Chain Conveyor Calculator: Minimum Between Rail Width on Curves Determine the minimum width of your curved conveyor Get Quote Live Roller Conveyors; If you have guardrails on your curve and the package being conveyed is too long, the package may become jammed in the curve if the curve is not wide enough Conveyor Curve Calculator Configure Curved Roller Conveyors

⚡Chain and Sprocket Calculator RPM and Chain Speeds

The lower the chain revolutions, the more frequently each chain link engages the same sprocket tooth, so greater and more uneven the wear When changing sprockets, you can adjust Chain Links to maintain (nearest to) current Sprocket Centers (eg: to keep motorcycle rear wheel within adjustment range)As a specialist in the field of conveyor technology, Bechtel can also help you with design questions of chain conveyors Download PDF Calculations We provide you with the basic calculations for the determination of chain speed, capacity per hour, weight of the material to be conveyed, as well as the calculation of the required powerChain conveyor calculations Bechtel GmbHThe calculator is designed to return pulley, belt and chain information for a given set of circumstances The measurements may be in millimetres or inches, as long as they are the same throughout There are five main sections in the calculator, dealing with pulleys and belts (or chains and sprockets see below ), together with speedPulley, Belt and Chain Information CalculatorConveyor Chain Pull Calculation Software 2 452 035 Normal friction factor for average conditions over 20 degree F to move empty belt 1000 Kg or L Use this calculator to calculate the force, torque and power required from a conveyor to move a load at an angleConveyor Chain Pull Calculation SoftwareContact Automated Conveyor Systems, Inc 3850 Southland Drive West Memphis, AR 72301 Call: 8707325050 Fax: 8707325191Automated Conveyor Systems, Inc Engineering Calculations

CALCULATION Required data for chain calculation

to design/calculate your conveyor Chain pull calculation – straight running conveyors 64 ENGINEERING MANUAL EM Edition 14 • 06/2006 Chain pull calculation elevators Power absorption 66 ENGINEERING MANUAL Chain/belt Lubrication Wearstrip material material Stainless steel, UHMWPE NoluS Return Extra Csteel PA roller SSE Dry 050 0 Enter any 3 known values to calculate the 4th If you know any 3 values (Pulley sizes or RPM) and need to calculate the 4th, enter the 3 known values and hit Calculate to find the missing value For example, if your small pulley is 80mm diameter, and spins at 1000 RPM, and you need to find the second pulley size to spin it at 400 RPM, Enter Pulley1 80, Pulley 1 RPM 1000, Pulley 2 RPM 400, and Pulley Calculator RPM, Belt Length, Speed, Animated DiagramsHorsepower CalculationSlider Bed Conveyor Instructions 1 Enter values in the "Enter Value" column 2 If you do not know a value, and a default value is given, you do not have to enter a value 3 If you do not know a value, and no default is given, you may enter a value on one of the option lines 4Sparks DURADRIVE PLUS HP CalculationSlider Bed ConveyorIntralox offers comprehensive conveyance solutions including conveyor belting, conveyor equipment, and services to help you optimize your plantIntralox Conveyor Belts, Equipment, and Services IntraloxL = (Chain Length in Pitches x Chain Pitch in Inches)/12 Slow Speed Selection If the linear chain speed is less than 160 ft/min, then a chain that is one size smaller than selected with the above method may be used To verify, check to see if the calculated chain tension (T) is less than the “Rated Working Load” of the chainRoller Drive Chain Selection and Engineering Information

conveyor torque calculation Gear Pulley engineering

Jan 09, 2009 I am asking for a professional confirmation that my calculations are correct theorywise The pallets are fixed to an aluminium articulating block chain and are supported by precision bearing wheels (mu = 0075)The loop is 60 mtr The weight of moving parts and load is 140kg/mtr and the velocity 24mtr/miniii Contributors Supervising Editor Kyosuke Otoshi Director Chain Products Division Editor Makoto Kanehira Manager Chain Products Division Production Engineering The Complete Guide to Chain TsubakiChoose from our selection of conveyor chain belting, sprockets for conveyor chain belts, ANSI roller chain attachment links, and more In stock and ready to shipConveyor Chain McMasterCarr Plastic Chain Conveyor Calculator: Minimum Between Rail Width on Curves Determine the minimum width of your curved conveyor Get Quote Live Roller Conveyors; If you have guardrails on your curve and the package being conveyed is too long, the package may become jammed in the curve if the curve is not wide enough Conveyor Curve Calculator Configure Curved Roller Conveyorsto design/calculate your conveyor Chain pull calculation – straight running conveyors 64 ENGINEERING MANUAL EM Edition 14 • 06/2006 Chain pull calculation elevators Power absorption 66 ENGINEERING MANUAL Chain/belt Lubrication Wearstrip material material Stainless steel, UHMWPE NoluS Return Extra Csteel PA roller SSE Dry 050 0 CALCULATION Required data for chain calculation

Chain Calculation Tool FlexLink Knowledge Base

Chain Calculation Tool Last Modified on 06/11/2019 11:08 am CET The Chain calculation tool (FLCT) is a client based tool used to perform advanced chain tension calculations on FlexLink based conveyorsConveyor Chain Pull Calculation Software 2 452 035 Normal friction factor for average conditions over 20 degree F to move empty belt 1000 Kg or L Use this calculator to calculate the force, torque and power required from a conveyor to move a load at an angleConveyor Chain Pull Calculation SoftwareThe calculator is designed to return pulley, belt and chain information for a given set of circumstances The measurements may be in millimetres or inches, as long as they are the same throughout There are five main sections in the calculator, dealing with pulleys and belts (or chains and sprockets see below ), together with speedPulley, Belt and Chain Information CalculatorEnter any 3 known values to calculate the 4th If you know any 3 values (Pulley sizes or RPM) and need to calculate the 4th, enter the 3 known values and hit Calculate to find the missing value For example, if your small pulley is 80mm diameter, and spins at 1000 RPM, and you need to find the second pulley size to spin it at 400 RPM, Enter Pulley1 80, Pulley 1 RPM 1000, Pulley 2 RPM 400, and Pulley Calculator RPM, Belt Length, Speed, Animated DiagramsHorsepower CalculationSlider Bed Conveyor Instructions 1 Enter values in the "Enter Value" column 2 If you do not know a value, and a default value is given, you do not have to enter a value 3 If you do not know a value, and no default is given, you may enter a value on one of the option lines 4Sparks DURADRIVE PLUS HP CalculationSlider Bed Conveyor

Cirrus FastTrack PF System Info Cirrus Conveyors

An average system chain pull will typically range between 15% and 5% of the sum of the moving load Maximum chain pull for a single drive is 750pounds Contact Cirrus for chain pull calculations that relate to your system Typical System Components Power Rail Components See our FastTrack Conveyor System page for details on the Calculation check of a specified chain For inspection of a selected chain, we made the calculation of real ratios in the chain transmission and then compare them with allowed values A new selection must be made, if the suggested chain does not correspond with these values Circumferential velocity of the chain v = [ms ]1Calculation of chain transmission czretezyczIntralox offers comprehensive conveyance solutions including conveyor belting, conveyor equipment, and services to help you optimize your plantIntralox Conveyor Belts, Equipment, and Services IntraloxIn these early days conveyor chain was generally of cast link construction The Company therefore has unrivalled experience in the production of highest quality cast link chains in ductile irons and steel under the “Climax Quality Brand”Conveyor Chain Design and Selection John King Chainsdriven live roller conveyor you require A chain driven live roller conveyor is a conveyor where the product rides directly on the carrying rollers These carrying rollers have sprockets welded to them, which in turn are powered by a chain This manual will explain the various types of Mathews chain driven live roller conveyors manufactured by Chain Driven Live Roller Conveyor

Technical page 6 Pacific Conveyors

Technical Page 6 HORSEPOWER CALCULATIONS : FOR CHAIN DRIVEN LIVE ROLLER CONVEYORS: Formula: PRODUCT WEIGHT (1) (lbs) Total weight of product on conveyor + CHAIN WEIGHT (lbs) weights and tables + ROLL WEIGHT (lbs) weights and tables + DRIVE WEIGHT (lbs) Best estimate (for small drives, use 250 lbs) BELT PULL DUE TO ACCUMULATED PRODUCT Chain Construction The Roller Chains generator is intended to design chain drives with roller and bush chains The chains can have single strand or multiple strands The doublepitch chains are also supported Typical construction of roller and bush chains is shown in the following picture The main difference is that bush chain does not have a rollerRoller Chain Calculation Basics Inventor 2016 Autodesk