Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

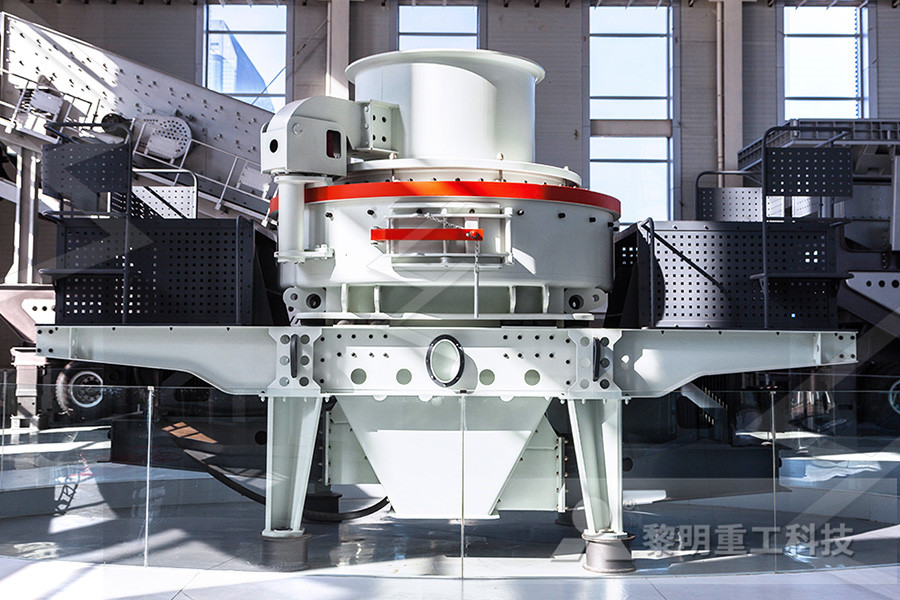

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Gold Wash Plants for Sale Portable Gold Mining Equipment

Allinclusive gold wash plants Our wash plants for sale are always mercuryfree, and they require no additional recovery equipment Setting up your wash plant is fast and easyit usually takes less than 2 hours When you need to move the mining site, you can Gold mining plants are supplied for both alluvial gold mining, and the hard rock gold mining operations DOVE gold mining plants are designed according to your ore’s characteristics, and minerals composition with the aim of highest recovery to micron size particles, with no lossGold Mining Plants For Alluvial And Hard Rock Mininggold extraction and recovery processes for gold plant There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship gold extraction and recovery processes for gold plantThe IGR 3000 Gold Recovery Plant was designed for a nominal 30 tons per hour feed rate based on an alluvial type material with moderate clay contamination Material is loaded into the plant feed hopper through a static scalping grizzly with 75 mm bar spacing Oversize is to be periodically removed manually from the grizzlyGold Recovery, iCON Gold Recovery, Gravity Concentrators Gold Recovery Gold recovery takes place in mines across the world Like most other industries, gold extraction must strike the delicate balance between controlling operating costs and maximising the return on investment (whilst maintaining environmental responsibility too) Choosing the right activated carbon supplier is vital to thisGold Recovery Jacobi Carbons

Gold Wash Plant Prices Cost of a M300 Wash Plant More

Gold Wash Plant Prices Purchase Your Gold Wash Plant Today Our custom gold wash plants are available for purchase Take a look at our gold wash plant prices and feel free to The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation characteristicsGold processing 101 Mining MagazineMay 01, 2013 Highlights Gold phytomining is potential route for economic exploitation of precious metal Metal extraction is by hyperaccumulating plant species from low grade ore bodies Phytomining has potential to meet the increasing demand of gold in metal market Economy depends on soil metal content, metal uptake, plant biomass, metal price Technology is environment friendly, aesthetically Phytomining of gold: A review ScienceDirectGold Extraction And Recovery Processes For Gold Plant Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%gold extraction and recovery plantThe IGR 3000 Gold Recovery Plant is designed for a nominal 30 tons per hour of solids The true limit of the plant is 20 tph of 2mm sand based on the capacity of the concentrators The overall capacity is 30 tph total or 20 tph sand, whichever comes firstGold Recovery, iCON Gold Recovery, Gravity Concentrators

gold extraction and recovery processes for gold plant

gold extraction and recovery processes for gold plant There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship Nov 07, 2019 It uses thiosulphate in conjunction with innovative plant technology to achieve gold extraction – at levels and returns that have been proven at an industrial scale A trial undertaken in 201718 achieved gold liberation at a p80 greater than 300 microns, with leach reagent consumption at 16 kg/t – the majority of this entrained loss with How to set up an ecofriendly gold processing plant Gold Wash Plant Prices Purchase Your Gold Wash Plant Today Our custom gold wash plants are available for purchase Take a look at our gold wash plant prices and Gold Wash Plant Prices Cost of a M300 Wash Plant MoreGold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Mining Process, Gold Recovery Process, Process Plant

Gold processing 101 Mining Magazine

The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation May 01, 2013 Highlights Gold phytomining is potential route for economic exploitation of precious metal Metal extraction is by hyperaccumulating plant species from low grade ore bodies Phytomining has potential to meet the increasing demand of gold in metal market Economy depends on soil metal content, metal uptake, plant biomass, metal price Technology is environment friendly, aesthetically Phytomining of gold: A review ScienceDirectGold Extraction And Recovery Processes For Gold Plant Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%gold extraction and recovery plantJun 20, 2019 Clean Mining’s CSIRO demonstration plant, Western Australia “Eliminating cyanide and the associated tailing dams from the gold recovery process is a gamechanger for the sector and Cyanidefree gold processing technology hits Concentrates from the CC are cleaned up on a Wave Table, to produce clean gold ready to be smelted and turned into a gold bar for sale Centrifugal Concentrators efficiently recover fine gold Gold Recovery Plant For Sale Contact Ian for details, including how to source a new 13 TPH Centrifugal Concentrator for under US$10K! There are larger Gold Recovery Plant For Sale: Centrifugal Concentrator for

Gold Recovery : 8 Steps (with Pictures) Instructables

The Borax Method is a technique of artisanal gold mining, with its basis in the principle that borax reduces the melting point of all minerals, including precious metals like gold The melting point of gold is 1063 ˚C, which is a higher temperature than can be obtained by cheap torches and burnersGold Extraction an overview ScienceDirect Topics Fort Knox cyanidation plant processes 38,000 tpd of a lowgrade (10 g/t Au), freemilling gold ore with a low metallic sulfide component (below 03%), by gravity (11% recovery) and by cyanidation (89% recovery)gold extraction plant with high recovery rateGoldlands' technicians have designed and manufactured proprietory industrial gold mining equipment since 1977 The mining machinery manufactured include a host of Gold Recovery and Mineral Processors including Gold Concentrators and Separators, Portable Placer or Alluvial Wash Plants, Portable Crushers, Trommels and Scrubbers, Gold Centrifuges, Jig Recovery Units, Rotary Helix Gold Mining Equipment for SaleConcentrates from the CC are cleaned up on a Wave Table, to produce clean gold ready to be smelted and turned into a gold bar for sale Centrifugal Concentrators efficiently recover fine gold Gold Recovery Plant Gold Recovery Plant For Sale: Centrifugal Concentrator for Gold extraction technology found in the modular gold plant includes enhanced gravity recovery as well as sulfide associated gold recovery via flotation The gravity circuit has been designed to maximize recovery Modular Gold Plants Proprietary Resources Gold Technology

How to set up an ecofriendly gold processing plant

Nov 07, 2019 It uses thiosulphate in conjunction with innovative plant technology to achieve gold extraction – at levels and returns that have been proven at an industrial scale A trial undertaken in 201718 achieved gold Gold Extraction an overview ScienceDirect Topics Fort Knox cyanidation plant processes 38,000 tpd of a lowgrade (10 g/t Au), freemilling gold ore with a low metallic sulfide component (below 03%), by gravity (11% recovery) and by cyanidation (89% recovery)gold extraction plant with high recovery rateGold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery Mining Process, Gold Recovery Process, Process Plant To be clear, these results are more than 220% the global average in gold recovery Processing methods used in the mining industry involve the use of cyanide and mercury These methods are so toxic to humans, plants It Started With An Idea New Gold Recoveryfor the chemical refining of gold from chloride media has shown considerable promise for the selective extraction of gold from silver, platinumgroup metals (PGMs), and base metals, and has potential applications in the refining of gold from various feed materials During the past year, two pilotplant Gold refining by solvent extraction—the Minataur™ Process

Phytomining of gold: A review ScienceDirect

May 01, 2013 Highlights Gold phytomining is potential route for economic exploitation of precious metal Metal extraction is by hyperaccumulating plant species from low grade ore bodies Phytomining has potential to meet the increasing demand of gold in metal market Economy depends on soil metal content, metal uptake, plant Jun 20, 2019 Clean Mining’s CSIRO demonstration plant, Western Australia “Eliminating cyanide and the associated tailing dams from the gold recovery process is a gamechanger for the sector and Cyanidefree gold processing technology hits The Borax Method is a technique of artisanal gold mining, with its basis in the principle that borax reduces the melting point of all minerals, including precious metals like gold The melting point of gold Gold Recovery : 8 Steps (with Pictures) InstructablesMay 01, 2011 The plant configuration presented in Table 8 as “CIL 2” illustrates the modifications that would be needed in the CIL plant for it to achieve the same gold extraction efficiency as the CIP plant These include almost doubling the carbon inventory from 75 to 145 t /stage, doubling the amount of gold locked up in the plant Factors influencing the rate of gold cyanide leaching and Trusted Industry Leader MSI has a Large selection of Gold Mining Equipment or Gold Recovery Equipment with Gold Machine like Gold Trommel, Gold Wash Plant, Sluice Box, Gold Shaking Table, Portable Gold Trommel, Portable Gold Wash Plant, Gold Concentrator, Gold , Gold Jig, Duplex Jig, Grizzly Feeder, Conveyor, Gold Gold Mining Equipment Msi Mining

ExtracTec Gold recovery and mining concentration equipment

We offer low, medium and highcapacity solutions for Alluvial and Hard Rock gold extraction as well as for other mineral recovery applications and for lead remediation of shooting ranges Our mobile solutions offer unbeatable recovery High extraction technology and accurate evaluation; Flexible account settlement system, including purchasing, bullion return and recovery as precious metal products; Strict confidentiality on TANAKA Precious Metals|Recovery and Refining