Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

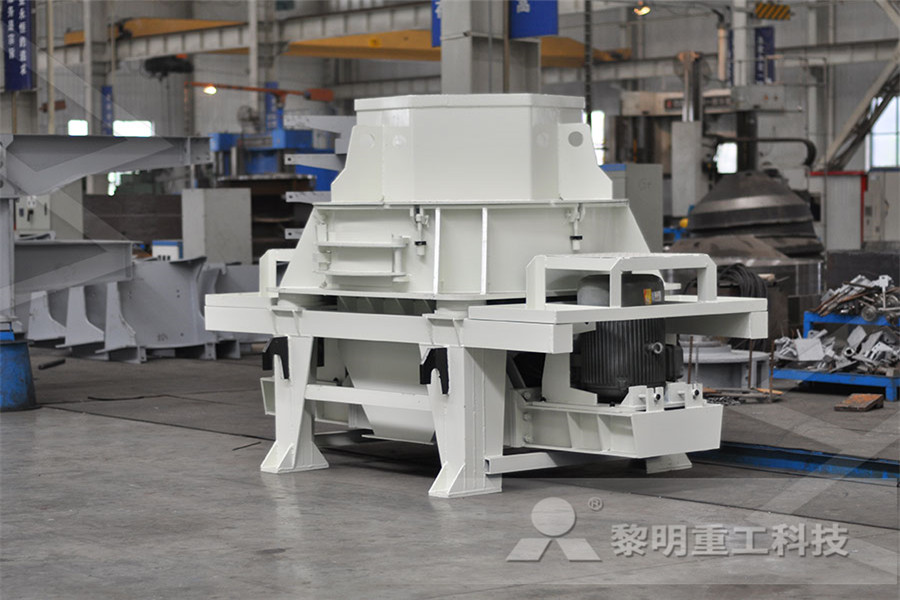

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Coal cement World Coal Association

Apr 28, 2015 It takes about 200 kg of coal to produce one tonne of cement and about 300400 kg of cement is needed to produce one cubic metre of concrete Coal combustion products (CCPs), such as Fly Ash also play an important role in cement manufacture and in the construction industry generallyAround 25 tonnes of coal are used to make 100 tonnes of cement Cement industry is power intensive and about 120 kwh of power is required to produce one tonne of cement More details » Get Price Alternative Fuels in Cement Manufacturing InTechHow much coal is required to produce one tonne of cementFeb 25, 2006 The average amount of energy needed to create 1 gramm of portland cement is at least 1700 Joule The world production of cement in 2002 was 1,800 million metric tons A quick calculation to find out how much energy was needed to create that much cement would be nice: 1,800,000,000,000,000 Gramm cement times 1700 Joule equalsAbout the energy needed for portland cement (1700J/g Coal is used to burn raw material to clinkering temp ie 1450 degree centigrade Low grade coal can be used for cement manufacturing but it will need high grade of limestone for good quality cement you can say low grade coal need high grade limestone and high grade coal need low grade limestone 56K views View 4 UpvotersWhat is the use of coal in the cement manufacturing May 01, 2017 Your question is very complicated 1 Calculation of the amount of fly ash in clinker: Assuming clinker heat consumption =780 kcal / kg of coal, coal air dry base calorific value of Qnet, ad=5900 kcal 8/ kg of coal, air dry base ash Aad=12% The amouHow much clinker is required to make one ton of cement

Fly ash Wikipedia

New fly ash production, ie, the burning of coal, produces approximately 20 to 30 tons of CO 2 per ton of fly ash Since the worldwide production of Portland cement is expected to reach nearly 2 billion tons by 2010, replacement of any large portion of this cement by fly ash could significantly reduce carbon emissions associated with Around 25 tonnes of coal are used to make 100 tonnes of cement Cement industry is power intensive and about 120 kwh of power is required to produce one tonne of cement More details » Get Price Alternative Fuels in Cement Manufacturing InTechHow much coal is required to produce one tonne of cementThe average energy input required to make one ton of cement is 44 million Btu—the equivalent of about 389 pounds of coal The US cement industry uses energy Cement Industry OverviewSubstituting one ton of coal fly ash or slag cement for one ton of Portland cement prevents almost one ton carbon dioxideemissions Manufacturing slag cement uses only 15% of the energy needed to make Portland cement The amount of natural materials required and the amount of landfill space used are both decreased, leading to cost savingsPortland Cement Manufacturing Industrial Resources CouncilAug 09, 2019 What’s more, mining and fabrication require the consumption of hydrocarbons Building enough wind turbines to supply half the world’s electricity would require nearly two billion tons of coal to produce the concrete and steel, along with two billion barrels of oil to make the composite bladesOne Wind Turbine Takes 900 Tons of Steel , 2500 Tons Of

Fly ash Wikipedia

New fly ash production, ie, the burning of coal, produces approximately 20 to 30 tons of CO 2 per ton of fly ash Since the worldwide production of Portland cement is expected to reach nearly 2 billion tons by 2010, replacement of any large portion of this cement by fly ash could significantly reduce carbon emissions associated with The decarbonation of limestone to give the calcium required to form silicates and aluminates in clinker releases roughly 053 t CO 2 per ton of clinker [8] In 2005, cement production (total cementitious sales including ordinary Portland cement (OPC) and OPC blends) had an average emission intensity of 089 with a range of 065–092 t CO 2 Cement Production an overview ScienceDirect TopicsThe industrial sector, which encompasses manufacturing, mining, agriculture, and construction, accounted for almost a third of total US energy use in 2012Energyintensive manufacturing accounted for a little more than half of total industrial energy use Although the cement industry used only onequarter of one percent of total US energy, it is the most energyintensive of all The cement industry is the most energy intensive of all Aug 16, 2014 45 tons of rebar (steel) are required so that equals 12645 tons of CO2 are emitted To create a 1,000 Kg of Portland cement, calcium carbonate (60%), silicon (20%), aluminium (10%), iron (10%) and very small amounts of other ingredients are heated in a large kiln to over 1,500 degrees C to convert the raw materials into clinkerHow Much CO2 Gets Emitted to Build a Wind Turbine? – STOP Cement only makes up between 10 and 20% of concrete’s mass, depending on the specific concrete However from an embodied energy and emissions point of view it makes up more than 80% So, if we want to make emissionsfree concrete we really need to figure out how to make emissionsfree cementCan You Make a Wind Turbine Without Fossil Fuels? Energy

COAL CONSUMPTION Page 1 of 1 International Cement Review

Dec 01, 2009 asuming a coal of very low heat value, 5500 kcal/kg as indicated by Mr ovancantfort, leads to a coal economy of 144 480 000 000 / 5500 = kg coal this is 26269 tons coal Therefore, even assuming a very poor coal, we get a 20% lower coal economy ReplyJul 09, 2020 For wind turbines, oil and natural gas are used to fabricate fiberglass blades, and coal is used to make steel and concrete Some perspective: if wind turbines were to supply half the world’s electricity, nearly 2 billion tons of coal would have to be consumed to produce the concrete and steel, along with 15 billion barrels of oil to make Green Energy Reality Check: It's Not as Clean as You Think What are Cement Clinkers? – wiseGEEK: clear answers for Jul 21, 2012 such as fly ash from coal burning, furnace slag, and other industrial byproducts what amount of clinker is required to produce 1 ton of cement? »More detailedhow to calculate amount of coal required to produce Feb 15, 2020 The basic general concrete purpose is made of 1 part of cement, 2 parts of sand and 3 parts of gravel Water is added to these ingredients to make a paste filled with gravel Generally, you do not want to add more water than you need Too much water makes for the weakness of concrete when it How Much Cement, Gravel and Sand do I Need? GoodHome IDSSubstituting one ton of coal fly ash or slag cement for one ton of Portland cement prevents almost one ton carbon dioxideemissions Manufacturing slag cement uses only 15% of the energy needed to make Portland cement The amount of natural materials required and the amount of landfill space used are both decreased, leading to cost savingsPortland Cement Manufacturing Industrial Resources Council

Coal utilisation in the cement and concrete industries

Jan 01, 2013 As of 2009, world cement output was estimated at 304 billion tonnes (metric tons) 6 China represents 561% of the world’s output while the USA represents 20% 7 Fuel used by the US cement industry is 60% coal, 13% petroleum coke, and 3%, natural gas 8 According to the US Energy Information Administration (EIA), the manufacture of cement Coal is only used for burning the klin to 1400°c to produce the concrete The other method to produce concrete is by fly ash Which again is not coal but a by product of burning coal which flies out and is collected using electrostatic precipitation So whatever coal floats your boat to reach 1400° or to make fly ash will serve the purposeWhich type of coal use by cement industryDec 01, 2009 asuming a coal of very low heat value, 5500 kcal/kg as indicated by Mr ovancantfort, leads to a coal economy of 144 480 000 000 / 5500 = kg coal this is 26269 tons coal Therefore, even assuming a very poor coal, we get a 20% lower coal economy ReplyCOAL CONSUMPTION Page 1 of 1 International Cement ReviewAug 09, 2019 Building enough wind turbines to supply half the world’s electricity would require nearly two billion tons of coal to produce the concrete and steel, along with two billion barrels of oil to make the composite blades More than 90% of the world’s solar panels are built in Asia on coal One Wind Turbine Takes 900 Tons of Steel , 2500 Tons Of Aug 22, 2019 To supply half the world’s electricity using wind turbines would require nearly two billion tons of coal to produce the concrete and steel and two billion barrels of oil to make the blades And, most (over 90 percent) of the world’s solar panels are built in Asia with electric power heavily fueled by coalThe Physical Impossibility of Renewable Energy Meeting the

Green Energy Reality Check: It's Not as Clean as You Think

Jul 09, 2020 For wind turbines, oil and natural gas are used to fabricate fiberglass blades, and coal is used to make steel and concrete Some perspective: if wind turbines were to supply half the world’s electricity, nearly 2 billion tons of coal would have to be consumed to produce the concrete and steel, along with 15 billion barrels of oil to make Feb 15, 2020 The basic general concrete purpose is made of 1 part of cement, 2 parts of sand and 3 parts of gravel Water is added to these ingredients to make a paste filled with gravel Generally, you do not want to add more water than you need Too much water makes for the weakness of concrete when it How Much Cement, Gravel and Sand do I Need? GoodHome IDSAug 16, 2014 45 tons of rebar (steel) are required so that equals 12645 tons of CO2 are emitted To create a 1,000 Kg of Portland cement, calcium carbonate (60%), silicon (20%), aluminium (10%), iron (10%) and very small amounts of other ingredients are heated in a large kiln to over 1,500 degrees C to convert the raw materials into clinkerHow Much CO2 Gets Emitted to Build a Wind Turbine? – STOP Cement only makes up between 10 and 20% of concrete’s mass, depending on the specific concrete However from an embodied energy and emissions point of view it makes up more than 80% So, if we want to make emissionsfree concrete we really need to figure out how to make emissionsfree cementCan You Make a Wind Turbine Without Fossil Fuels? Energy What are Cement Clinkers? – wiseGEEK: clear answers for Jul 21, 2012 such as fly ash from coal burning, furnace slag, and other industrial byproducts what amount of clinker is required to produce 1 ton of cement? »More detailedhow to calculate amount of coal required to produce

Alternative Fuel Use in Cement Manufacturing

Canada’s cement industry has made progress over past two decades in each of these areas Energy intensity improved by 21% between 1990 and 2010 There have also been improvements in the clinkertocement ratio and the use of alternative fuels is growing As a result, the overall GHG intensity of cement manufacturing in Canada has decreased by How much clinker is required to make one ton of cement Mar 08, 2017 Your question is very complicated 1 Calculation of the amount of fly ash in clinker: Assuming clinker heat consumption =780 kcal / kg of coal, coal air dry base calorific value of Qnet, ad=5900 kcal 8/ kg of coal, air dry base ash Aad=12% The amou 【Service Online】is coal a raw material in cement NIJHUIS ARCHITECTUURHow much clinker is used to make one ton of cement Answers reduction of 526% in the amount clinker required per ton of cement cement means that 095 tons of clinker can make 105 tons of cement Substituting one ton of coal fly ash or slag cement for one ton of Portland Read more 2011 Cement Report:Layout 1 Carbon War on making 1 ton of cement,how many clinker in ton needed