Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

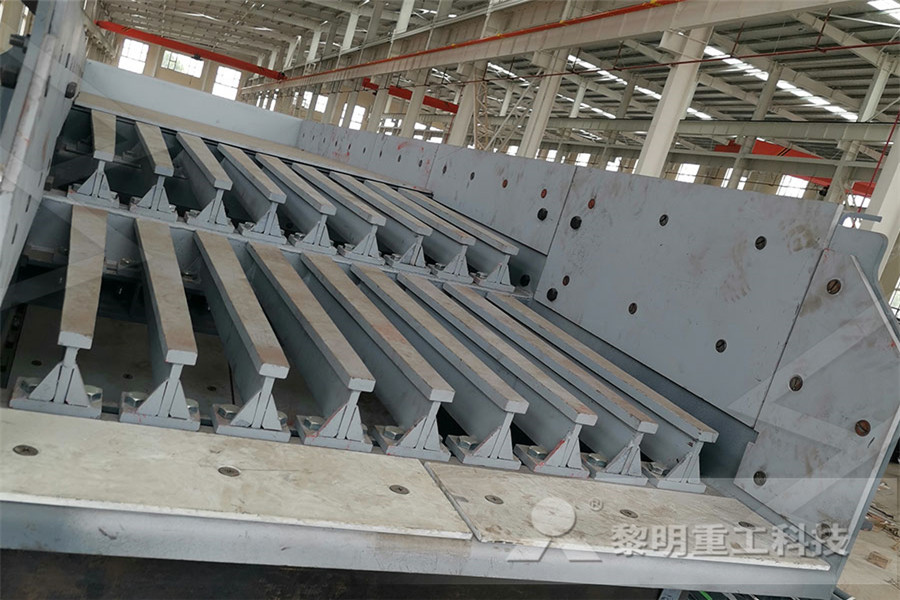

FH heavy vibrating feeder

-

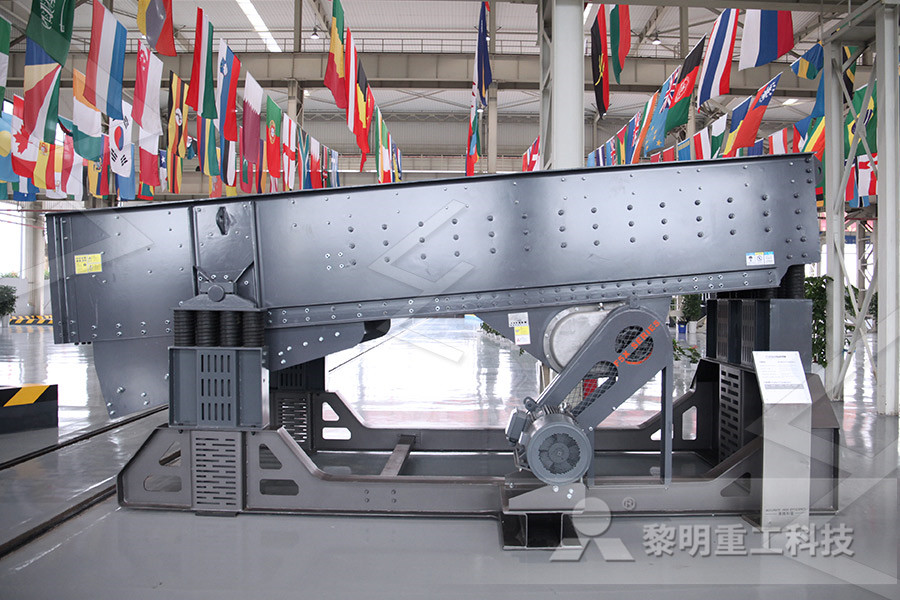

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Material Safety Data Sheet on Machine Coolant

Material Safety Data Sheet (There are a lot of really bad MSDS sheets If you are a manager you need an MSDS sheet that will protect you and your employees from hazards and that will qualify as valid during government inspections Also see our Article on Machine Coolant Health and Safety, According to a report from the National Renewable Energy Laboratory, wind turbines are predominantly made of steel (7179% of total turbine mass), fiberglass, resin, or plastic (1116%), iron or cast iron (5 17%), copper (1%), and aluminum (02%) According to the 2017 Wind Technologies Market Report, many turbine components are domestically sourced and manufactured (in the United States)What materials are used to make wind turbines?Interface Performance Materials' millboard materials are strong, thin, dense boards with excellent insulating characteristics They are made from ceramic fiber, clay, inert fillers and a small amount of organic and/or inorganic binders for increased handling strengthThermal Millboard :: Interface Performance MaterialsMATERIAL SAFETY DATA SHEET STEEL MILL SCALE SECTION I MATERIAL IDENTIFICATION Manufacturer's Name Emergency Telephone Number Gerdau AmeriSteel 813/2868383 Contact Telephone Number for Information Matt D Moore 813/2868383 Director, Safety Health Date MATERIAL SAFETY DATA SHEET STEEL MILL SCALEThe feed to ball mills (dry basis) is typically 75 vol% ore and 25% steel The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones The cyclones send correctsize material on to flotation and direct oversize material back to the ball mill for further grinding View chapter Purchase bookBall Mill an overview ScienceDirect Topics

Cold Rolling Mill for Aluminium Sheet

The aluminium cold rolling mill can process the Aluminium coil in thickness of 610mm from casters and hot rolling The proceed materials can be offered to produce sheet, strip, can, PS sheet, foil and precision raw material for further processing According to the gauge of the coils, it can beAn Introduction to Millable Dental Materials Determine which materials are the best fit for your laboratory By Chris Brown, BSEE Before one can make the business decision to invest in CAM milling technology, it is first necessary to ask what types of materials and substructures do I want to mill?An Introduction to Millable Dental Materials Inside ©2016 MachiningCloud, Inc End Mill Materials 7 End Mill Materials End mills are made out of either cobalt steel alloys (known as high speed steel, or HSS), or from tungsten carbide in a cobalt lattice (shortened to "carbide") High Speed Steel (HSS): Provides good wear resistance and costs less than cobalt or carbide end millsIntroduction to Milling Tools and Their ApplicationUnlike milling in most other materials, coolant is always recommended to assist in chip removal, to control heat at the cutting edge and to prevent the recutting of chips High pressure coolant (70 bar (1015 psi)) applied through the spindle/tools is always to How to do milling in different materialsOther materials that have been tried include steel, various composites and carbon filamentreinforcedplastic (CFRP) As the rotor size increases on larger machines, the trend will be toward high strength, fatigue resistant materialsWind Turbine Materials and Manufacturing Fact Sheet

What materials are used to make wind turbines?

According to a report from the National Renewable Energy Laboratory, wind turbines are predominantly made of steel (7179% of total turbine mass), fiberglass, resin, or plastic (1116%), iron or cast iron (5 17%), copper (1%), and aluminum (02%) According to the 2017 Wind Technologies Market Report, many turbine components are domestically sourced and manufactured (in the United States)Cool for 175 hours (20°F or 11°C per hour) to get to 1100°F (593°C) In case of oil quenching, heat the material to 1750°F (955°C) first for each inch of thickness For pancake forgings (tensile strength of 142,000 and yield strength of 126,500), the next steps apply: Normalizing – heat the material Steel 1722A Tech Steel MaterialsShingle roofs consist of overlapping panels made from a variety of materials such as fiberglass asphalt, wood, polymers, or metals How they can be made cool: Buy cool asphalt shingles, which use specially coated granules that provide better solar reflectance (Coating existing asphalt shingles to make them cool, however, is not normally recommended or approved by shingle manufacturers)Cool Roofs Department of EnergyWhat is “My list“? “My list” is a function that keeps a list of the pages in this site that you view often My list can be viewed by clicking the “To view my list” buttonMilling MITSUBISHI MATERIALS CORPORATION2 Data was obtained from green parts, printed using Form 2, 100 µm, Tough settings, washed and air dried without post cure 3 Data was obtained from parts printed using Form 2, 100 µm, Tough settings, and postcured with 25 mW/cm² of 405 nm LED light for 120 minutes at 60 °C 1 Material Materials Data Sheet Formlabs

Mill test report (metals industry) Wikipedia

A mill test report (MTR) and often also called a certified mill test report, certified material test report, mill test certificate (MTC), inspection certificate, certificate of test, or a host of other names, is a quality assurance document used in the metals industry that certifies a material's chemical and physical properties and states a product made of metal (steel, aluminum, brass or Nov 10, 2011 Material Safety Data Sheet for Printing Ink and Related Materials: SECTION X – STABILITY AND REACTIVITY General: Stable under recommended storage conditions Conditions to Avoid: Heat, sparks, electrical equipment and open flames Incompatibility With Other Materials: Avoid contact with oxidizing materials Hazardous Polymerization: No dataMaterial Safety Data Sheet for Printing Ink and Related Norske Skog reviews future of Tasman newsprint mill in New Zealand October 15, 2020 Baden Board debt resettlement plan approved October 15, 2020 Modern Karton to convert RCCM PM 3 at its Tekirdag mill in Turkey to production of highquality coated containerboard grades October 15, Pulp and Paper Price Index RISI Fastmarkets RISIAs one of the world’s leading manufacturers of metal composite materials, ALPOLIC ® carefully considers every detail of the manufacturing, distribution and sales process Most of our products are manufactured in Chesapeake, VA, many with a substantial amount of postconsumer recycled materialsALPOLIC® Materials Aluminum Metal Composite Materials Toray Advanced Composites specializes in multiple composite and carbon fiber materials and processes for the world's aerospace, space/satellite, highperformance automotive racing, highend industrial, and athletic footwear posite and carbon fiber materials and processes Toray

Materials An Open Access Journal from MDPI

Materials (ISSN 19961944; CODEN: MATEG9) is a peerreviewed open access journal of materials science and engineering published semimonthly online by MDPI The Portuguese Materials Society (SPM), Spanish Materials Society (SOCIEMAT) and Manufacturing Engineering Society (MES) are affiliated with Materials and their members receive a discount on the article processing chargesD2 Tool Steel D2 Tool Steel is a versatile highcarbon, highchromium, airhardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromiumrich alloy carbides in the microstructure These carbides provide good resistance to wear from sliding contact with other metals and abrasive materials Although other steels with improved toughness or High Speed Steel D2 Steel D2 Technical DataSections of an SDS The original intent of the GHS was to bring some consistency and coherency to the hazard information available to workers Material Safety Data Sheets (MSDSs), the original versions of documents containing chemical hazard information prior to GHS, had as many formats as the imaginations of chemical suppliers would allow, leading to confusion and lost time including during SDS / MSDS Database Safety Data Sheets Library Get the Specs Full Spec Guide Freight Policy ARCAT Spec Guide ARCAT Spec Wizard Green/LEED Products 2010 Lead Abatement Resources EPA Renovation, Repair and Painting Guide Kachina Lead Paint Solutions Hanley Wood Article FAQ by NAHB FAQ by NARI Renovate Right Brouchure Material Safety Data Sheets Copolymer Siding, Gables, Vents, Mounts, Accessories Copper Leaf Relief []Mastic Technical Data Ply GemJan 11, 2016 Colloid mill works on the rotorstator principle The equipment breaks down materials by forming dispersion of materials in a liquid Shearing takes place in a narrow gap between a static cone (the stator) and a rapidly rotating cone (the rotor) To reduce wear, the rotor and stator are constructed using toughened steel or corundumColloid Mill: Operating Principles, components, Uses

Thermal Millboard :: Interface Performance Materials

Interface Performance Materials' millboard materials are strong, thin, dense boards with excellent insulating characteristics They are made from ceramic fiber, clay, inert fillers and a small amount of organic and/or inorganic binders for increased handling strengthAccording to a report from the National Renewable Energy Laboratory, wind turbines are predominantly made of steel (7179% of total turbine mass), fiberglass, resin, or plastic (1116%), iron or cast iron (5 17%), copper (1%), and aluminum (02%)What materials are used to make wind turbines?The 4Hi Cold Rolling Mills are used for rolling of coils, sheets and plates of all types of metals and alloys like Stainless Steel, Mild Steel, Brass, Copper, CuproNickel, Aluminum etccold rolling mills for sheet, cold rolling mills for strip Aug 14, 2019 Nevertheless, The material is not a solid metal at all, but a matrix composed of tungsten carbide (which itself is tungsten and carbon in equal parts) held together with a binder–typically cobalt In addition, there may be a very thin end mill coating to further enhance performance More about end mill coatings belowSolid Carbide End Mill Coatings, Grades, and GeometriesThe aluminium cold rolling mill can process the Aluminium coil in thickness of 610mm from casters and hot rolling The proceed materials can be offered to produce sheet, strip, can, PS sheet, foil and precision raw material for further processingCold Rolling Mill for Aluminium Sheet

Steel 1722A Tech Steel Materials

Cool for 175 hours (20°F or 11°C per hour) to get to 1100°F (593°C) In case of oil quenching, heat the material to 1750°F (955°C) first for each inch of thickness For pancake forgings (tensile strength of 142,000 and yield strength of 126,500), the next steps apply: Normalizing – heat the material Unlike milling in most other materials, coolant is always recommended to assist in chip removal, to control heat at the cutting edge and to prevent the recutting of chips Highpressure coolant (70 bar (1,015 psi)) applied through the spindle/tools is always to be preferred instead of How to mill in different materials Sandvik CoromantA Mill Test Report (MTR) documents a material's physical and chemical properties These quality assurance certificates show a metal product's compliance with international standards ANSI and ASME are two of the most important and common standards that require MTR information Other names for mill test reports include:What is a Mill Test Report? Paul Mueller CompanyLooking for MSDS information regarding the chemicals in a commercial product or a material safety data sheet (MSDS)? Here is THE most complete MSDS list on the Internet, and it's free! By federal law, manufacturers must supply this info in an MSDS which we provide here, FREE!The Most Complete Free Material Safety Data Sheet (MSDS 2 Data was obtained from green parts, printed using Form 2, 100 µm, Tough settings, washed and air dried without post cure 3 Data was obtained from parts printed using Form 2, 100 µm, Tough settings, and postcured with 25 mW/cm² of 405 nm LED light for 120 minutes at 60 °C 1 Material Materials Data Sheet Formlabs

Mastic Technical Data Ply Gem

Get the Specs Full Spec Guide Freight Policy ARCAT Spec Guide ARCAT Spec Wizard Green/LEED Products 2010 Lead Abatement Resources EPA Renovation, Repair and Painting Guide Kachina Lead Paint Solutions Hanley Wood Article FAQ by NAHB FAQ by NARI Renovate Right Brouchure Material Safety Data Sheets Copolymer Siding, Gables, Vents, Mounts, Accessories Copper Leaf Relief []Norske Skog reviews future of Tasman newsprint mill in New Zealand October 15, 2020 Baden Board debt resettlement plan approved October 15, 2020 Modern Karton to convert RCCM PM 3 at its Tekirdag mill in Turkey to production of highquality coated containerboard grades October 15, Pulp and Paper Price Index RISI Fastmarkets RISIAs one of the world’s leading manufacturers of metal composite materials, ALPOLIC ® carefully considers every detail of the manufacturing, distribution and sales process Most of our products are manufactured in Chesapeake, VA, many with a substantial amount of postconsumer recycled materialsALPOLIC® Materials Aluminum Metal Composite Materials