Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

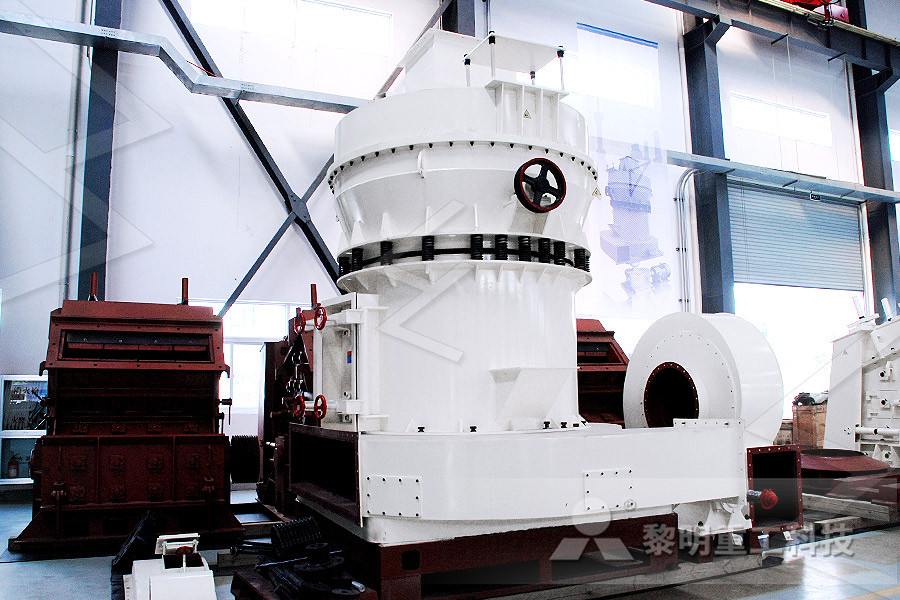

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Convert Micro to Milli Unit Converter

How to Convert Micro to Milli 1 µ = 0001 m 1 m = 1000 µ Example: convert 15 µ to m: 15 µ = 15 × 0001 m = 0015 m Convert Micro to Other Prefixes UnitsThe micro gimbal project aims to provide 50x zoom electrooptical and custom thermal (LWIR) imaging, and a range of smart enhancements in a sub 220g system The gimbal will include significant onboard video processing capabilities that will enable the next generation of image processing, video compression and smart featuresMicro Gimbal UAV Gimbal UAV Camera Ascent VisionM2D MICRO STABILIZED GYRO STABILIZED EO/IR PLATFORM IN THE PALM OF YOUR HAND 160 Grams VISUAL CAMERA IMAGER OPTICAL ZOOM LOW COST DAY 1 NIGHT IMAGING IN A MICRO GYRO STABILIZED GIMBAL The M2D Micro Gimbal is a revolution in gyro stabilized technology The M2D is unbelievably compact at 3" tall and a mere 2" in diameterM2D MICRO STABILIZED GIMBAL SPI CorpDec 10, 2020 Go for the Proxxon Micro Mill FF 230 The biggest plus with this machine is that it runs really smoothly and the noise is minimal Definitely not one of those lowquality models that let off annoying squeaky sounds With a robust motor and a Poly V drive system, the mini mill is able to achieve speeds of up to 2500 RPM 10 Best Mini Milling Machine Reviews in November 2020May 15, 2019 The gimbal has been designed in a way that it can be easily folded and stored inside a bag or carried in hands Its folding mechanism is quite good and it never feels flimsy It also allows MOZA MiniS Gimbal to be quite portable despite sporting a larger design The gimbal is mainly made of plastic but it feels high qualityMOZA MiniS Gimbal: Our First Look and Impression Beebom

(PDF) Micro Cmgs for Agile Small Satellites: Design and In

MICRO CMGs FOR AGILE SMALL SATELLITES: DESIGN AND INORBIT TESTS Angular rate (Pitch) c) CMG Torque d) Gimbal Rates e) Gimbal Angles f) Nov 20, 2020 The erie tools etdsmmill small mill comes with a highspeed steel 6 pieces 4 flutes also with ⅜ inches shank cutter The set includes a long range of cutter sizes Also, it can do both end milling and face milling The end milling capacity is ⅜ inches, and the face milling capacity is ⅝ inchesBest Mini Milling Machine 2021 FRESH Reviews, Guides FAQs››More information from the unit converter How many mil in 1 microns? The answer is 00157 We assume you are converting between mil and micron You can view more details on each measurement unit:Convert mil to microns Conversion of Measurement Unitswhich gimbal rate to a mill with a micro Mill With Scourges Gimbal Pto Coal Russian Online Message If you are interested in our products or what we can do to help you you can always consult our customer service Quick response within 30 Small scale trammel Track Stone Crusher Br 200mill with scourges gimbal pto qubicalwestlandnlFind here online price details of companies selling Mini Rice Mill Get info of suppliers, manufacturers, exporters, traders of Mini Rice Mill for buying in IndiaMini Rice Mill at Best Price in India

Convert Micro to Milli Unit Converter

How to Convert Micro to Milli 1 µ = 0001 m 1 m = 1000 µ Example: convert 15 µ to m: 15 µ = 15 × 0001 m = 0015 m Convert Micro to Other Prefixes UnitsBy having an offgimbal EIM, the gimbal can be adapted to a number of different platforms without requiring any ongimbal CCA modifications The stabilized 2axis micro gimbal has onboard precision MEMS gyros containing highly miniaturized electronics with direct drive system and stabilization performance of 80 µRad (line of site jitter)Stabilized Micro Gimbals Ascendant Engineering SolutionsFeb 17, 2020 Zhiyun has been making quite splash in the phone gimbal market and the SmoothQ, 3axis Handheld Gimbal is a good example of why The SmoothQ is light, effective and extremely affordable and with its stunning 360 degree rotation it adds a whole new element to your video capabilities It’s one of a new generation of smartphone gimbals that allow you to plug your phone in 7 Best Smartphone Gimbals in 2020 [Buying Guide] – Gear HungryNov 20, 2020 The erie tools etdsmmill small mill comes with a highspeed steel 6 pieces 4 flutes also with ⅜ inches shank cutter The set includes a long range of cutter sizes Also, it can do both end milling and face milling The end milling capacity is ⅜ inches, and the face milling capacity is ⅝ inchesBest Mini Milling Machine 2021 FRESH Reviews, Guides FAQsSep 01, 2016 2208 Gimbal Motors Micro Gimbal Controller HMBGC 2/3 Axis Driver BRAND NEW! ProfessorX: Aircraft Electric Multirotor (FS/W) 0: Dec 10, 2016 01:06 AM: Discussion: Micro Brushless Gimbal V30: A Tiny 3Axis 32Bit Gimbal: OlliW: Multirotor Drone Electronics: 1: Micro gimbal? RC Groups

Convert mil to microns Conversion of Measurement Units

››More information from the unit converter How many mil in 1 microns? The answer is 00157 We assume you are converting between mil and micron You can view more details on each measurement unit:How to use: Choose a type of operation (drilling, reaming, boring, counterboring, face milling, slab milling/side milling, end milling, or turning), select your stock material, choose a material for the tool (highspeed steel or carbide), input the quantity of teeth for the tool and the diameter of the workpiece/cutter Hit the "Calculate Speeds and Feeds Calculator Good CalculatorsAMG Gimbal Aerotech's AMG position and rate optical mounts and gimbals provide ultraprecise angular position, rate and acceleration for development and production testing of a wide range of systems The AMG More > (+) QuickSpecs AOM360D DirectDrive GimbalGimbals and Optical Mounts Aerotech IncJul 24, 2009 I struggle with the speeds and feed rates for "small" ball end mills (003125, 0040, 00625) when cutting our typical tool steels such as P20, A2, and H13 We are limited to a maximum spindle speed of 15,000 rpmHow Do You Get The Cutting Parameters Right For Small End The feed rate of the material must be matched to the optimal speed of the end mill A 50% reduction in operating speed can double the life span of your end mill Choose the correct flute count for the application proper chip evacuation is crucial as heated cutters can lead to lowquality cutting (burnt material, burred edging and dull tooling)End Mills The Essential Beginners Guide

6 Ways to Optimize HighFeed Milling MoldMaking Technology

Apr 17, 2020 And it’s true, if not applied properly, highfeed milling can create some unfavorable results For those willing to take the leap, the benefits of highfeed milling can significantly outweigh the potential challenges The process offers amazing productivity, nearly triple the metal removal rate of conventional methods, and increases tool lifethe Gen1 technology These systems close rate loops directly about each gimbal axis Rate sensors such as small mechanical sensing gyros are used to sense angular rates relative to inertial space These rates are summed with the steering commands to stabilize and steer each axisStabilization, Steering, and Gimbal Technology as it Aug 12, 2008 However, unlike traditional milling, which is less forgiving, micromilling requires a tighter quality relationship within every machine component In other words, if there is a slight quality issue with the spindle, chances are it will have a negative effect on Understanding MicroMilling Machine Technology Feed Rates Explained – Extend the Life of Your Tools and Machines Feed Rate is one of the most important factors to consider when implementing any strategy Simply put, feed rate is the speed at which the cutter engages the part and is typically measured in units/minuteFeed Rates Explained – Extend the Life of Your Tools The milling process – definitions Cutting speed,v c Indicates the surface speed at which the cutting edge machines the workpiece Effective or true cutting speed, v e Indicates the surface speed at the effective diameter (DC ap)This value is necessary for determining the true cutting data at the actual depth of cut (a p)This is a particularly important value when using round insert cutters Milling formulas and definitions Sandvik Coromant

Speeds And Feeds For Milling With End Mills

Milling Speeds and Feeds Charts The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate We have broken these recommendations down into material categories so you can make better decisions with how to productively run your end millsMICRO CMGs FOR AGILE SMALL SATELLITES: DESIGN AND INORBIT TESTS Vaios Lappas(1), An operational gimbal rate of 9º/s was selected as a low risk and safe gimbal rate For costMICRO CMGs FOR AGILE SMALL SATELLITES: DESIGN AND Selection of h and max gimbal rate is a tradeoff between performance, size and singularity avoidance, Keep h as small as possible (less mass, volume), Avoid using large gimbal rates leading to large gimbal angle excursions, thus singularities, Proceedings of the World Congress on Engineering 2012 Vol IISimulation of Three Axis Attitude Control Using a Control Feed Rate Calculator When milling or drilling, or creating a tool path for a machine the feed rate must be determined Materials have rated surface speeds for a given type of cutter The harder the material the slower the speed Given the diameter of the tool and the surface speed, the RPMs of the spindle can be calculatedFeed Rate Calculator DaycounterThe feed rate of the material must be matched to the optimal speed of the end mill A 50% reduction in operating speed can double the life span of your end mill Choose the correct flute count for the application proper chip evacuation is crucial as heated cutters can lead to lowquality cutting (burnt material, burred edging and dull tooling)End Mills The Essential Beginners Guide

Using an external mic with the DJI Osmo Mobile 3 gimbal

Nov 15, 2019 Image credit: DJI Using an external mic with the DJI Osmo Mobile 3 would be a huge deal, you would essentially have a budget, no hassle, portable one man shooting set up This would give you the option to not only mount a shotgun mic, you could even have a wireless lapel mic set upApr 17, 2020 And it’s true, if not applied properly, highfeed milling can create some unfavorable results For those willing to take the leap, the benefits of highfeed milling can significantly outweigh the potential challenges The process offers amazing productivity, nearly triple the metal removal rate of conventional methods, and increases tool life6 Ways to Optimize HighFeed Milling MoldMaking TechnologyA few advanced end mill designs feature alleffective insert rows, in which each insert overlaps the next axially In this case, the number of flutes is the same as the number of effective rows See Figure 2 To determine the feed rate, use the following formula:Start With The Right Speeds And Feeds Modern Machine ShopDec 14, 2020 The Vivo X50 series came equipped with a microgimbal camera system for capturing stable videos The company will be offering an even better experience on the Vivo X60 as it Vivo X60 series design, key specs officially revealed nano to micro (n to µ) conversion 1 nano (n) is equal 0001 micro (µ) use this converter micro to nano (µ to n) conversion 1 micro (µ) is equal 1000 nano (n) use this converter milli to mega (m to M) conversion 1 milli (m) is equal 10E9 mega (M) use this converter mega to milli (M to m) conversionMetric Unit Converter Measurement conversion JZ

Milling Formula Calculator Carbide Depot

Milling Formula Interactive Calculator: Solve for any subject variable in bold by entering values in the boxes on the left side of the equation and clicking the "Calculate" button The solution will appear in the box on the right side of the equation CUBIC INCHES PER MINUTE METAL REMOVAL RATE (in³/min) Enter RPM