Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

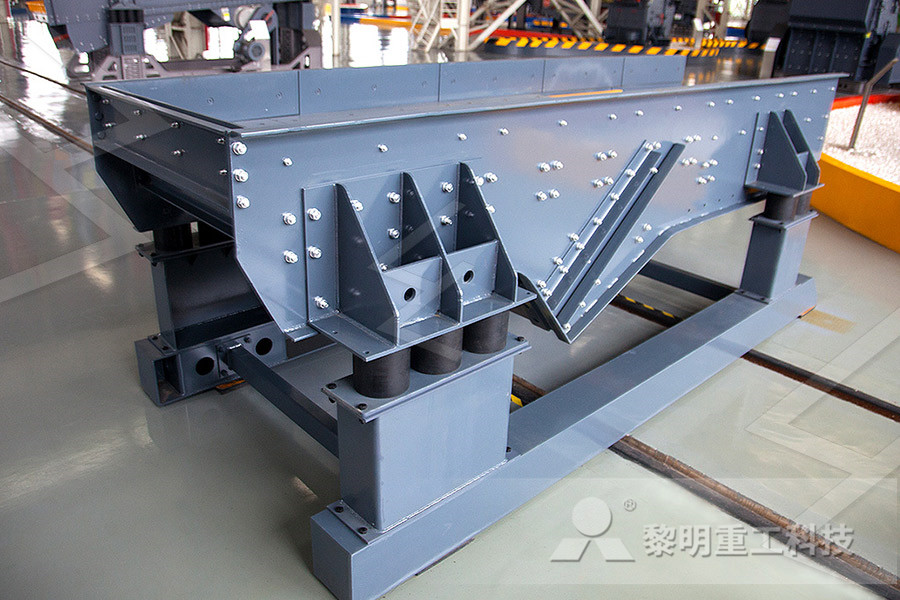

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Rotary Dryer Design Working Principle

Metallurgical ContentSizing a Rotary Dryer using a Capacity TableRotary Dryer Capacity TableROTARY DRYERS, DirectHeat DesignROTARY DRYERS, IndirectHeat DesignROTARY DRYERS, Tedrow Steam DesignRotary Dryer Direct Heat and Indirect Heat Type Capacity and Sizing Table For evaporating moisture from concentrates or other products from plant operations, Rotary Dryers are DIRECT HEAT DRYERS The Louisville Rotary Direct Heat Dryer provides a costeffective, proven method of drying a variety of both organic and inorganic materials Inlet gas temperature to the dryer can be optimized to suit the heat tolerance of the feedstock to provide maximum efficiencyRotary Dryer Design Manufacturing Louisvile Dryer CompanyIntroduction Direct heat rotary driers are used to lower the moisture content of materials passing through the dryer Materials are directly heated using heat from a combustion process; the fuel used is typically gas although pulverised coal, light fuel oil or waste process gasses could also be usedDirect Heat Rotary Dryer saVReeA simplied diagram of a directheat rotary dryer is presented in Figure 71 The direction of gas flow through the cylinder relative to the solids is dictated mainly by the properties of the (PDF) Modelling and design of rotary dryersApr 10, 2018 DIRECT HEATED ROTARY DRYER FOR SILICA SAND Required: “CONFIDENTIAL” Sha DESIGNED: Arberor MITA Design group“ELMAGERARD” 395 Total air mass 396 Sum of overall heat required (Q1 ) and total heat loss from gasses(Q2 ) 397 Heat loss from exhaust gases leaving the dryer 310 Heat loss from moisture in exhaust gases leaving the dryer Direct heated rotary dryer SlideShare

911metallurgistRotary Dryer Design amp Working

Whenever possible to apply heat direct to the material to be dried, Rotary Dryers of the Direct Heating Design are used If it is not possible to apply heat direct to the material to be dried, Rotary Dryers of the Indirect Heating Design can be furnished so that the heated gases will not come in direct contact with the materialNov 26, 2001 In direct heat rotary dryers, a hot gas flowing through the dryer provides the heat required for the vaporization of the water To promote gas–solid contact, most direct heat dryers have flights, placed parallel along the length of the shell, which lift solids and make them rain across the section of the dryer Fig 1)The design of flights in rotary dryers ScienceDirectRotary drying is one of the many drying methods existing in unit operations of chemical engineering The drying takes place in rotary dryers, which consist of a cylindrical shell rotated upon(PDF) 7 Rotary Drying ResearchGateA rotary dryer is said to be of the direct type if, by virtue of its design, heat is added to or removed from the solids by direct exchange between the gas and solids The direct heat dryers are the simplest and the most economical class They are used when direct contact with the hot gas or air is not detrimental to the fedRotary Dryer: Operating principle, Classifications, Uses Academiaedu is a platform for academics to share research papers(PDF) Rotary Dryer Handbook Niel vd Merwe Academiaedu

Rotary Dryer Machine Design and Working Principle Sunco

For evaporating the moisture from the wet raw material, Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption The rotary dryer machines has the direct heating type, in direct heating type Direct heating type rotary dryer machine are used to apply heat / hot air to contact and heat the raw material such as sawdust, wood chips, chicken manure, silica A rotary dryer is said to be of the direct type if, by virtue of its design, heat is added to or removed from the solids by direct exchange between the gas and solids The direct heat dryers are the simplest and the most economical classRotary Dryer Engineering Design HandbookNov 26, 2001 In direct heat rotary dryers, a hot gas flowing through the dryer provides the heat required for the vaporization of the water To promote gas–solid contact, most direct heat dryers have flights, placed parallel along the length of the shell, which lift solids and make them rain across the section of the dryer Fig 1 )The design of flights in rotary dryers ScienceDirectRotary Dryer Capacity Table ROTARY DRYERS, DirectHeat Design Size of Dryer Cap Tons per 24 Hours Dimensions RPM HP of Motor Shipping Weight Lbs Motor Drive L W H 24″dx15’1 18 26’6″ 3’8″ 7’9″ 7½ 3 12,000 24″dx20’1 25 31‘6″ 3’8″ 8’2″ 7½ 3 13,000 36″dx20’1 55 33’0″ 4’10” 8’8″ 5 5 14,400 1/7911metallurgistRotary Dryer Design amp Working Most of the drying takes place while the material falls through the air blast Using very hot air or combustion gases, rotary dryers can also function as roasters for nuts, sesame seeds, and cocoa beans A detailed method for the design of rotary dryers, based on a heat exchange approach has been described by Nonhebel (1971)Rotary Dryers an overview ScienceDirect Topics

Indirect Drying vs Direct Drying FEECO International Inc

And while direct fired rotary dryers are most often the selected drying method, indirect rotary dryers are a valuable alternative for specific processing needs The Difference Between Indirect and DirectFired Dryers Operation While both types of dryers are comprised of a rotating drum in which the processing occurs, these two types of dryers The dryer is positioned at a slight slope to assist gravity and the slow rotation of the drum ensures efficient and uniform drying as the material is tumbled down the length of the vessel We supply rotary dryers where the heat energy is applied directly or indirectly, with an external heat source, as in the case of a steamtube dryerRotary Dryers Our Process Equipment British RemaModel predictions compare satisfactorily with the operating data of an indirect heat industrial lignite dryer Overall heat transfer coefficients of the pilot rotary dryer were found to agree well with those reported for direct heat dryersINDIRECT THERMAL DRYING OF LIGNITE: DESIGN ASPECTS Rotary dryers are a class of dryer commonly used in industry to dry particulate solids (Keey, 1972) They are made of a long cylindrical shell that is rotated The shell is usually slightly inclined to the horizontal to induce solids flow from one end of the dryer to the other In direct heat rotary dryers, a hotA STUDY OF PARTICLE MOTION IN ROTARY DRYERRotary Dryer Design Working Principle Of the different types of dryers that there are the most common is the ROTARY DRUM DRYER/Kiln, This type of drier is common not only in the mining industry but you will find them in fertilizer plants, Cement plants, and peat hogs to name but a few In direct heat rotary dryers, a hotrotary drum dryer design pdf bookingshotelsnl

Hemp Dryers Vulcan® Drying Systems

Rotary Drum Dryer The workhorse of the Vulcan® Drying Systems Hemp Dryer is the heavyduty, lowtemp, directheating rotary drum dryer The lowtemp dryer is extremely energyefficient and can be configured to utilize a variety of fuels to perform the drying processDryers can be: Adiabatic or direct in which heat is supplied by direct contact of the solid with a hot gas, usually air Indirect in which heat is supplied by an external medium such as electricity, steam, and such Figure 1 shows five different designs of direct dryersSolid Dryer Design Lecture Notes on Unit OperationsHeat and mass energy balances in designing a dryer for food applicationsPlease provide feedback on this module by selecting Like or Dislike Your feedbacDryer Design Heat and Mass Energy Balance YouTubeThe rotary dryer design consists principally of a rotating cylinder that is enclosed in a furnace along its active length With heat transfer indirect and through the cylinder wall, the gas velocities within an indirect dryer are low as compared to a direct heat dryer, and correspondingly, the offgas system is smaller and more economicalRotary Dryer Schenck ProcessFor evaporating the moisture from the wet raw material, Rotary Dryers are designed and constructed for high efficiency and economy in fuel consumption The rotary dryer machines has the direct heating type, in direct heating type Direct heating type rotary dryer machine are used to apply heat / hot air to contact and heat the raw material such as sawdust, wood chips, chicken manure, silica Rotary Dryer Machine Design and Working Principle Sunco

Selecting Rotary Direct Heat Dryers powderbulksolids

A rotary direct heat dryer seems to be a basic and simple piece of equipment It consists of a steel tube that rotates on a set of steel tires (riding rings), which rests on a set of rollers (trunnions) and is powered by a gear or chain drive Material is fed into one end and usually discharges out the other endA rotary dryer is said to be of the direct type if, by virtue of its design, heat is added to or removed from the solids by direct exchange between the gas and solids The direct heat dryers are the simplest and the most economical classRotary Dryer Engineering Design HandbookThe cocurrent directheat rotary dryer is the most common, wet material is in contact with the hot gas stream as its highest temperature, which causes rapid evaporation of surface moisture As it progresses through the dryer, heat energy is lost to the material it is drying and it leaves the dryer at a comparatively low temperatureRotary Dryer Industrial Rotary Dryers Manufacturer from PuneMost of the drying takes place while the material falls through the air blast Using very hot air or combustion gases, rotary dryers can also function as roasters for nuts, sesame seeds, and cocoa beans A detailed method for the design of rotary dryers, based on a heat exchange approach has been described by Nonhebel (1971)Rotary Dryers an overview ScienceDirect TopicsRotary Drum Dryer The workhorse of the Vulcan® Drying Systems Hemp Dryer is the heavyduty, lowtemp, directheating rotary drum dryer The lowtemp dryer is extremely energyefficient and can be configured to utilize a variety of fuels to perform the drying processHemp Dryers Vulcan® Drying Systems

Design Calculation Of Rotary Dryer

Modelling and design of rotary dryers A mathematical model is developed for predicting the performance of direct heat cocurrent rotary dryers equipped with lifting flights Although the motion of solids and the drying process are intermittent in nature they have been treated as if they were continuous by considering the effective valuesApr 15, 2014 Heat and mass energy balances in designing a dryer for food applicationsPlease provide feedback on this module by selecting Like or Dislike Your feedbacDryer Design Heat and Mass Energy Balance YouTubeWhen the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirectheated type Often, indirect heated dryers are used when product contamination is a concern In some cases, a combination of directindirect heated rotary dryers are also available to improve the overall efficiencyRotary dryer WikipediaIndirect Heat Transfer Dryer with Rational Design Rotary Dryer Low Cost and High Return Energy Saving,US $ 6,985 36,000 / Set, New, Rotary Drying Equipment, Henan Read more used indirect dryers for sale Iron beneficiation and Indirect Heating Rotary Dryer mayukhportfoliocoDryers in the United States Location Type of Dryer Type of Biosolids Dried Milwaukee, WI Direct, rotary Blend of raw secondary with digested primary Baltimore, MD (Patapsco) Direct, rotary Blend of raw primary with secondary North Andover, MA Direct, rotary Anaerobically digested Newport, TN Indirect, rotary chamber Anaerobically digestedBiosolids Technology Fact Sheet, Heat Drying

Direct Vs Indirect Drying SlideShare

Nov 04, 2015 DirectFired Dryers Directfired rotary dryers rely on direct contact between the material and the drying air to dry the material 8 Flights, or material lifters, pick up the material, and drop it through the air stream in a cascading motion to maximize heat transfer efficiencyROTARY DRYER : The Rotary Dryer is a type of industrial dryer employed to reduce or to minimize the liquid moisture content of the material it is handling byRotary Dryer YouTubeRotary drum dryer adopts slightly tilted drum which can be rotated The wet materials are sent to hopper of rotary dryer by belt conveyor or bucket elevator from the higher side, and welldried materials are collected from the other lower side, and hot air enters the drum from the feeding side or discharging side according to user needsRotary Drum Dryer manufacturers and suppliers Exceed