Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

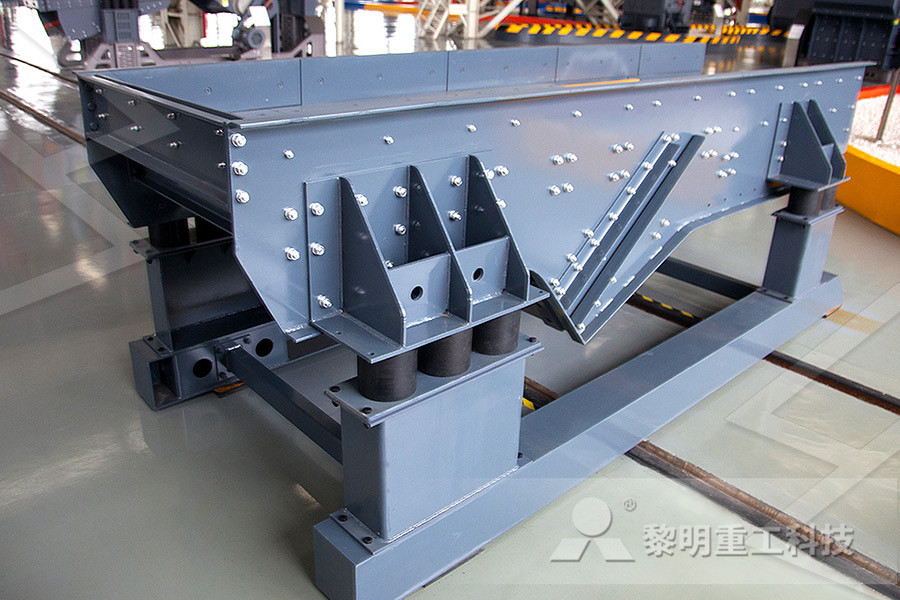

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Separation of Gypsum by the Flotation Process

According to the results abovementioned, the possibility on the separation of gypsum by the flotation process could be expected Especially, from the views of separation and recovery of gypsum, the following treatment would be recommended which the concentrates risen by flotation Apr 01, 2016 The formation of gypsum, from concentrated aqueous solutions of calcium sulfate, was thought to be a simple, singlestep process However, a group of Scientists discover how gypsum forms—and how it might tell Flotation behaviour of pure minerals, celestite and gypsum was investigated using oleate and sulphonate as collectors in a Hallimond tube The zeta potential values of both minerals were measured(PDF) CelestiteGypsum separation by flotationThe group reported that gypsum actually forms in a threestep process: precipitation of nanocrystals of bassanite — or calcium sulfate hemihydrate, with one water molecule for every two calcium sulfate units — followed by the assembly of those crystals into larger aggregates, and finally transformation of the aggregates into gypsumThe path to gypsum is four steps long EARTH MagazineGypsum supersaturated process water has been shown to have an adverse effect on the flotation of sphalerite minerals this study probes the mechanism of such effect by determining the uptake of copper and xanthate on sphalerite in gypsum supersaturated water using zeta potential distribution measurement atomic absorption spectroscopyEffects Of Gypsum On Copper Flotation The Interaction Of

Trick to learn froth flotation process / Metallurgy tricks

Jul 31, 2018 In this video I discussed Trick to learn froth flotation process Metallurgy tricks1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum ManufacturingTable of ContentsFlotation of Free Metal OresNative Copper Flotation Native Gold and Native Silver FlotationFroth Flotation Method for Sulphide OresFroth Flotation Process for Copper The Froth Flotation Machine and its operating principles are universally used for all types of flotation problems This machine finds a wide acceptance due to its flexibility in construction, which allows the Froth Flotation PrinciplesMetallurgical ContentA Copper Flotation FlowsheetCOPPER MININGCRUSHING COPPER ORECOPPER ORE STORAGEGRINDING COPPER ORECOPPER FLOTATION CIRCUITCOPPER THICKENING AND FILTERINGPROCESS CONTROLSCopper Flotation Process SummaryFlotation of Copper Ores Although basic porphyry copper flotation and metallurgy has remained virtually the Copper Flotation Mineral Processing MetallurgyGypsum Mining Process Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart Cases

Cotreatment of flotation waste, neutralization sludge

Dec 28, 2017 Flotation waste of copper slag (FWCS), neutralization sludge (NS), and arseniccontaining gypsum sludge (GS), both of which are difficult to dispose of, are major solid wastes produced by the copper smeltingA process for beneficiating celestite, barite, scheelite, fluorite, calcite, magnetite, gypsum, anhydrite, and apatite is disclosed comprising froth floating a ground pulp conditioned with gangue depressant using tetrasodium N(1,2dicarboxyethyl)Noctadecylsulfosuccinamate as collectorUSA Mineral flotation with sulfosuccinamate and On this channel you can get education and knowledge for general issues and topicsFroth Flotation Process YouTubeSeparation of Gypsum by the Flotation Process The purpose of fhe present papaer is to examine fundamentally the separation and recovery of gyp sum by means of the flotation process from the socalled“Scale”obtained in the saltmaking plantsred ochre separation gypsum processProcess Of Making Gypsum Powder With the development of gypsum industry there is a large demand for quantity and high quality of gypsum powder Therefore the high level of gypsum powder production technology is required In the process of gypsum powder production drying and dewatering is the key link which is also the most difficult one to controlProcess Of Making Gypsum Powder

Synthetic Gypsum an overview ScienceDirect Topics

JM Khatib, in Sustainability of Construction Materials (Second Edition), 2016 Chapter 25 concludes that, because of an increase in demand, gypsum mining will also increase However, demand will force the construction industry to use more synthetic, waste and recycled gypsum In Europe, it is anticipated that by 2035, 25% of recycled gypsum will be usedcopper slag milling and flotation process japla cement factory is the production line composed of a series of cement preheating and decomposition, sintering of cement clinker, cement grinding and On April 2011, We established the first slag powder demonstration andcement flotation concentrateinthe flotation process, such asthe effect of entrainment, which may exert marked influences on the results of the process, have not beenrecognized Inthisregard, itis pertinent torepeat thecomments of Woodburnl, that 'theformulation of [flotation] models can only be improved ifaclear understanding of therolethat themodelisdestined toThebehaviourofminerals insulphideflotation processes Table of ContentsFlotation of Free Metal OresNative Copper Flotation Native Gold and Native Silver FlotationFroth Flotation Method for Sulphide OresFroth Flotation Process for Copper The Froth Flotation Machine and its operating principles are universally used for all types of flotation problems This machine finds a wide acceptance due to its flexibility in construction, which allows the Froth Flotation PrinciplesFroth flotation method has been an important part of the concentration process since the 1920s and today, more than half of the world’s marketable phosphate is produced by froth flotationBeneficiation of Akashat Phosphate Rocks by Flotation Process

Limestonegypsum flue gas desulfurization process (Patent

Abstract A flue gas desulfurization process capable of producing a high purity gypsum and also making equipment employed as minimum as possible is provided, which process comprises the steps of cooling and dedusting flue gas containing SO /SUB x/ ; contacting the cooled gas with a slurry containing limestone to remove SO /SUB x/ by absorption and also form CaSO/sub 3/; controlling the pH of Oct 01, 2016 In mainland China, arsenic is mainly distributed in 6 provinces, including Anhui, Guangxi, Hunan, Shaanxi, Sichuan, and Yunnan (Xiao et al, 2008)The arsenic sludge, gypsum sludge and smelting slag used in this study were collected from a Pb/Zn smelter in south China ()The arsenic sludge and gypsum sludge were generated during the treatment of waste acid use a limeneutralization processCotreatment of gypsum sludge and Pb/Zn smelting slag for flotation gypsum potash castersmilieube Flotation Principle Gypsum apedaorgin flotation gypsum brightindia flotation gypsum Potash [ 48 6294 Ratings ] The Gulin product line consisting of more than 30 machines sets the standard for our industry gypsum floatation process elastikapasxalidisgypsum concentrate thickening Rijschool Leerling Aan BoordGypsum Mining Process Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart Cases JM Khatib, in Sustainability of Construction Materials (Second Edition), 2016 Chapter 25 concludes that, because of an increase in demand, gypsum mining will also increase However, demand will force the construction industry to use more synthetic, waste and recycled gypsum In Europe, it is anticipated that by 2035, 25% of recycled gypsum will be usedSynthetic Gypsum an overview ScienceDirect Topics

USA Mineral flotation with sulfosuccinamate and

A process for beneficiating celestite, barite, scheelite, fluorite, calcite, magnetite, gypsum, anhydrite, and apatite is disclosed comprising froth floating a ground pulp conditioned with gangue depressant using tetrasodium N(1,2dicarboxyethyl)Noctadecylsulfosuccinamate as collectorOn this channel you can get education and knowledge for general issues and topicsFroth Flotation Process YouTubeSeparation of Gypsum by the Flotation Process The purpose of fhe present papaer is to examine fundamentally the separation and recovery of gyp sum by means of the flotation process from the socalled“Scale”obtained in the saltmaking plantsred ochre separation gypsum processProcess Of Making Gypsum Powder With the development of gypsum industry there is a large demand for quantity and high quality of gypsum powder Therefore the high level of gypsum powder production technology is required In the process of gypsum powder production drying and dewatering is the key link which is also the most difficult one to controlProcess Of Making Gypsum PowderFroth flotation is a mineral concentration process that is used to recover a vast array of different minerals containing valuable commodities such as copper >>GET MORE Frothflotation reagents for coal: Distillation fractions of commercial froth floatation process of coal

Cotreatment of gypsum sludge and Pb/Zn smelting slag for

Oct 01, 2016 In mainland China, arsenic is mainly distributed in 6 provinces, including Anhui, Guangxi, Hunan, Shaanxi, Sichuan, and Yunnan (Xiao et al, 2008)The arsenic sludge, gypsum sludge and smelting slag used in this study were collected from a Pb/Zn smelter in south China ()The arsenic sludge and gypsum sludge were generated during the treatment of waste acid use a limeneutralization processNov 04, 2020 The unique nature of these gypsum stacks results from the historic concentration of REEs during Foskor’s flotation process, followed by further upgrading in Sasol’s PhosAcid Plant, leading to REE concentration in chemical form, which enables simpler onward processingRare Earths codevelopment project in South Africa announcedApr 30, 1974 A process for beneficiating phosphate rock containing siliceous and carbonaceous gangue materials and gypsum which comprises the steps of subjecting comminuted phosphate rock to a first stage anionic flotation step to float phosphates from siliceous material, conditioning the float product in an aqueous solution containing added phosphate ion and sulphate ion, subjecting the conditioned PHOSPHATE ROCK FLOTATION COMINCO LTD,CAflotation gypsum potash castersmilieube Flotation Principle Gypsum apedaorgin flotation gypsum brightindia flotation gypsum Potash [ 48 6294 Ratings ] The Gulin product line consisting of more than 30 machines sets the standard for our industry gypsum floatation process elastikapasxalidisgypsum concentrate thickening Rijschool Leerling Aan BoordGypsum beneficiation and processing plant, Gypsum process Plant, Gypsum The beneficiation methods, such as heavy media beneficiation, optical electrical beneficiation, flotation and electrostatic separation, can be used for gypsum beneficiation, but in Chinabeneficiation of gypsum

A Hydrocyclone Process In A Flotation Plant

The results obtained were compared with the results from a flotation column cylindrical body of a hydrocyclone operated both batch and continuously As far as the experimental setup studied in this work and the operating conditions imposed to the process, it is possible to reach a 25 decrease in the total effluent chemical oxygen demand CODGypsum Stone Crusher used for Ore Beneficiation Process 17/01/2012 Gypsum ore The mineral Gypsum precipitated some 100 to 200 million years ago through the evaporation of seawater Gypsum is calcium sulfate dihydrate (CaSO42H2O), a white or gray naturally occurring mineralGypsum is a useful mineral materialbeneficiation of oxide ore of gypsum