Solutions

Products

-

Primary mobile crushing plant

-

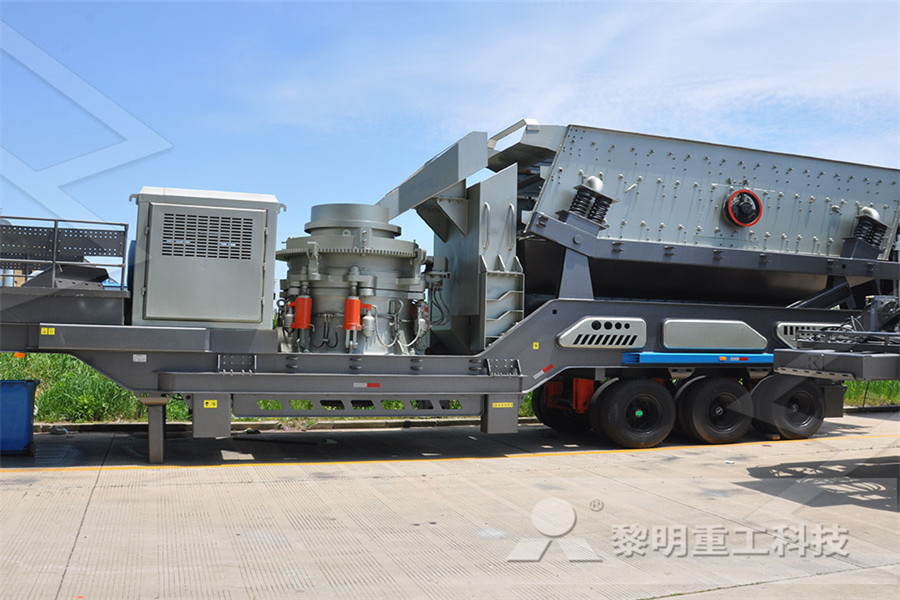

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding Machinespdf page 106 10 GRINDING \u2022

page 106 10 GRINDING • Grinding has two main uses, as a surface finishing process for flat or cylindrical features that have already been cut to cut complex surfaces with high tolerances or hard materials • The basic process involves an abrasive wheel spinning at high speed that is brought into contact with the work surface, thus giving a smooth finish 101 OPERATIONS 102 MACHINE 421 Rough grinding machines The rough grinding machines are used to remove stock with no reference to the accuracy of results Excess metal present on the cast parts and welded joints are removed by rough grinders The main types of rough grinders are: 1 Hand grinding machine 2 Bench grinding machine 3 Floor stands grinding machine 441 Introduction 42 Types of grinding machines 421 grinding machines, bufting machines and reciprocating surface grinding machines UTILITY GRINDING MACHINES The utility grinding machine is intended for offhand grinding where the workpiece is supported in the hand and brought to bear against the rotating grinding abrasive wheelGRINDING MACHINESenlist grinding machines pdf Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two Read More; CS Cone Crusher Comparing with other kinds of crushers, CS Series spring cone crusher is quite excellent in hard materialenlist grinding machines pdf hadlawplFig Types of surface grinding machines Tool and cutter grinder In grinding tools by hand a bench or pedastal type of grinder is used The tool is hand held and moved across the face of the wheel continually to avoid excessive grinding in one spot For sharpening miscellananeus cutters a universal type grinder is used 2 Types of Grinding wheels1 Grinding 11 Grinding and Abrasive Machines

Grinding and Finishing IIT Bombay

Grinding – Ex 11 • You are grinding a steel, which has a specific grinding energy (u) of 35 Ws/mm3 • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2 The motor has a power of 2 kW • The work piece moves (v) at 15 m/min The chip thickness ratio (r) is 109/Series Grinder Tableof Contents Operation and Programming Manual i Chapter 1 Using This Manual 47 Manual Machine Homing 411 48 MDI Mode 413 481 MDI Basic Operation 414 Chapter 5 Editing Programs On Line 9/Series Grinder Operation and Programming ManualHello viewers, so today we are going to study the Definition, Working, Types, and Operations of the grinding machineAnd at the end of the article, I will give you a PDF downloadable link so that you can download the PDF of the grinding machine as well In the manufacturing process grinding operation is also an important operation to make a finished product, so let's start the topicGrinding Machine: Types, Parts, Working Operations (With grinding machines perform the dressing task automatically The application of coolants to the grinding process is important Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life Coolants are either emulsions, synthetic lubricants or special grinding oilsBasics of Grinding ManufacturingMultiple Spindle Bar Machines •More than one spindle, so multiple parts machined simultaneously by multiple tools Example: six spindle automatic bar machine works on six parts at a time •After each machining cycle, spindles (including collets and workbars) are indexed (rotated) to next positionMACHINING OPERATIONS AND MACHINE TOOLS

Basics of Grinding Manufacturing

grinding machines perform the dressing task automatically The application of coolants to the grinding process is important Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life Coolants are either emulsions, synthetic lubricants or special grinding oilsThe maximum angular exposure of the grinding wheel periphery and sides for safety guards used on other portable grinding machines shall not exceed 180 deg and the top half of the wheel shall be enclosed at all times • Before using the tool on a workpiece, let it run for several minutes Watch for flutterABRASIVE WHEELS/GRINDERS – BENCH, FLOOR, AND HANDPDF By reducing setup time of a centreless grinding system, higher process productivity and a reduction of the total machining cost can be obtained Find, read and cite all the research (PDF) Centreless Grinding Simulation ResearchGateThe grinding machine is a 4 axis system, having three linear motion axes (x, y, and z) and one rotational axis, as shown in Table 1 The table work space is 400 x 400 mm The strokes of the x, y, and z axis are 500mm, 600mm and 200mm, respectively, and the c axis has a maximum rotational speed of 10rpm Analysis of a HighPrecision Grinding MachineMultiple Spindle Bar Machines •More than one spindle, so multiple parts machined simultaneously by multiple tools Example: six spindle automatic bar machine works on six parts at a time •After each machining cycle, spindles (including collets and workbars) are indexed (rotated) to next positionMACHINING OPERATIONS AND MACHINE TOOLS

LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS

1201 Welding Machines 1202 Bending Machines 1203 Presses 1204 Planers/Shapers 1205 Milling Machines 1206 Drilling Machines 1207 Boring Machine 1208 Lathe Machines 1209 Cutting/Shearing/Slotting Machines 1210 Threading/Rivetting Machines 1211 Grinding Machines 1212 Forging Smithy 1213 Material Holding Equipments TESTING MACHINES: 1301 Xray Peel grinding machines offer a modern approach that achieves flexible grinding operations of a variety of diameters, grooves, thrust faces and forms using one setup Peel grinding is often compared with hard turning where a tool is traversed along a hardened workpiece following an appropriate form Peel grinding operates in a similar mode removing a narrow strip of material as the grinding Grinding Machines an overview ScienceDirect TopicsDec 05, 2020 The drilling machine is defined as a machine which is used to make a circular hole, a tool used to drill the holes of different size and other related operations using a drill bit The drilling machine is one of the most important machines in a workshop As regards its importance it is second only to the lathe machinesHoles were drilled by the Egyptians in 1200 BC about 3000 years ago by Drilling Machine [Parts, Types, Tools, Operations] with PDFMilling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal These machines are also classified as kneetype, cutter containing a number of cutting edges The milling ramtype, manufacturing or bed type, and planertypeMILLING OPERATIONS TYPES OF MILLING MACHINESLathe Machines are used in metalworking, woodturning, metal spinning, thermal spraying, glass working, and parts reclamation The various other operations that you can perform with the help of Lathe Machine can include sanding, cutting, knurling, drilling, and deformation of tools that are employed in creating objects which have symmetry about the axis of rotationLathe Machine (PDF): Definition, Parts, Types, Operations

Home Samputensili

From grinding to shaving machines and from hobs to master gears we offer a comprehensive range of machines and cutting tools around world Along with strategic partner , we produce gear generating grinding, gear profile grinding, shaving, resharpening and chamfering machines as well as hobs, master, chamfering and chamferroller and deburring Machine tool Machine tool Basic machine tools: Hundreds of varieties of metal machine tools, ranging in size from small machines mounted on workbenches to huge production machines weighing several hundred tons, are used in modern industry They retain the basic characteristics of their 19th and early 20thcentury ancestors and are still classed as one of the following: (1) turning Machine tool Basic machine tools BritannicaWorldwide leading global supplier of high precision grinding machines for 120 years, more than 10,000 machines installed around the world UVA LIDKÖPING develops, markets, manufactures, and installs highprecision grinding machines with surrounding equipment within the area of high precision grindingUVA LIDKÖPING – Manufacturer of high precision grinding Tool and Cutter Grinder The universal tool and cutter grinder (Figure L25) is a type of cylindrical grinder However, this machine can also perform some limitedsurface grinding On these machines, the grinding head can be rotated around the vertical axis, and the workhead can be rotated and tilted in a variety of directionsTYPES OF GRINDING MACHINES – Cad cam Engineering WorldWide1201 Welding Machines 1202 Bending Machines 1203 Presses 1204 Planers/Shapers 1205 Milling Machines 1206 Drilling Machines 1207 Boring Machine 1208 Lathe Machines 1209 Cutting/Shearing/Slotting Machines 1210 Threading/Rivetting Machines 1211 Grinding Machines 1212 Forging Smithy 1213 Material Holding Equipments TESTING MACHINES: 1301 Xray LIST OF MAJOR CONSTRUCTION PLANTS EQUIPMENTS

MILLING OPERATIONS TYPES OF MILLING MACHINES

Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal These machines are also classified as kneetype, cutter containing a number of cutting edges The milling ramtype, manufacturing or bed type, and planertype– A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges (milling machine) • Types – Peripheral milling • Slab, slotting, side and straddle milling • Up Milling (Conventional) down milling (Climb) – Facing milling • Conventional face, Partial face, End, Profile, Pocket contour MACHINING OPERATIONS AND MACHINE TOOLSJul 16, 2018 A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting There are various grinding machine types, each with a different purpose Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas4 Types of Grinding Machines Maximum AdvantageCarolinasArcZone : Tungsten Grinding Machines Connectors, Reels Adapters MIG Guns, Feeders Parts Plasma Arc Cutting Plasma Arc Welding Purge Gas Equipment Remote Amperage Controls TIG Torches Accessories Tungsten Electrodes Tungsten Electrode Grinders Water Coolers, Coolant Parts Gas Flowmeters, Heaters, Mixers Stick Electrode Holders DIY Projects, Books DVD's Shop Tungsten Grinding Machines : ArcZone, Welding From grinding to shaving machines and from hobs to master gears we offer a comprehensive range of machines and cutting tools around world Along with strategic partner , we produce gear generating grinding, gear profile grinding, shaving, resharpening and chamfering machines as well as hobs, master, chamfering and chamferroller and deburring Home Samputensili

Toyoda Grinders

As a global leader in grinding machine technology, Toyoda offers an extensive lineup of highperformance universal, cylindrical, camshaft, and crankshaft grinding machines Originally designed for highproduction automotive manufacturing, these grinders excel in the most demanding applicationsvarious types of grinding process in our previous post, where we have discussed each grinding process in detail We have also discussed basic principle of grinding in our previous post, where we have seen the basics of grinding process and various abrasives materials as well as we have also noted the various factors affecting the quality of object surface created by grinding processAPPLICATIONS AND ADVANTAGES OF GRINDING PROCESS Worldwide leading global supplier of high precision grinding machines for 120 years, more than 10,000 machines installed around the world UVA LIDKÖPING develops, markets, manufactures, and installs highprecision grinding machines with surrounding equipment within the area of high precision grindingUVA LIDKÖPING – Manufacturer of high precision grinding KENT INDUSTRIAL CO, LTD was born in 1966 with President Mr CS Lu Today our company covers over 12,000 square meters and includes 200 staff members Our main products are: surface grinders, surface grinders, universal cylindrical grinders, creep feed grinders, double column surface grinders, vertical machining centers, high speed vertical machining centers, and double column KENT INDUSTRIAL CO, LTD Vertical Machining Center ANDRITZ designs and manufactures all key processing machines and offers complete feed pelleting plant solutions to the global animal feed and livestock industry ANDRITZ equipment for feed pelleting Our feed processing technologies are available in various models and with optional accessories to offer the optimum solution for your specific Animal Feed Processing ANDRITZ

Hardinge Turning, Milling, Grinding Workholding

Hauser multiaxis jig grinding machines are specially developed for applications requiring complex double curvature profiles where very high standards of surface finish and accuracy are essential Hauser machines are ideal for superfinished applications where accuracy must not be compromised Jig Grinders Hauser H45 400 + H55 400;Turn the grinder OFF and wait for the grinding wheel to completely stop 12 If necessary, loosen the clamp thumb screw and use the feed and lock wheels to advance and secure the drill bit toward the grinding wheel for additional sharpening, then repeat Steps 9–11 until you are satisfied with the cutting edge of the bit (see Figure 6) 13Model D4144 Drill Grinding Attachmentgrinding systems are still in common use throughout Africa today Newer crops, such as rice, maize and cassava, have been introduced in more recent centuries, and new milling techniques have followed In the midnineteenth century, electric motors were invented and higher speed machines, such as hammer and plate mills, began to replaceSmall mills in Africa Food and Agriculture Organization