Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

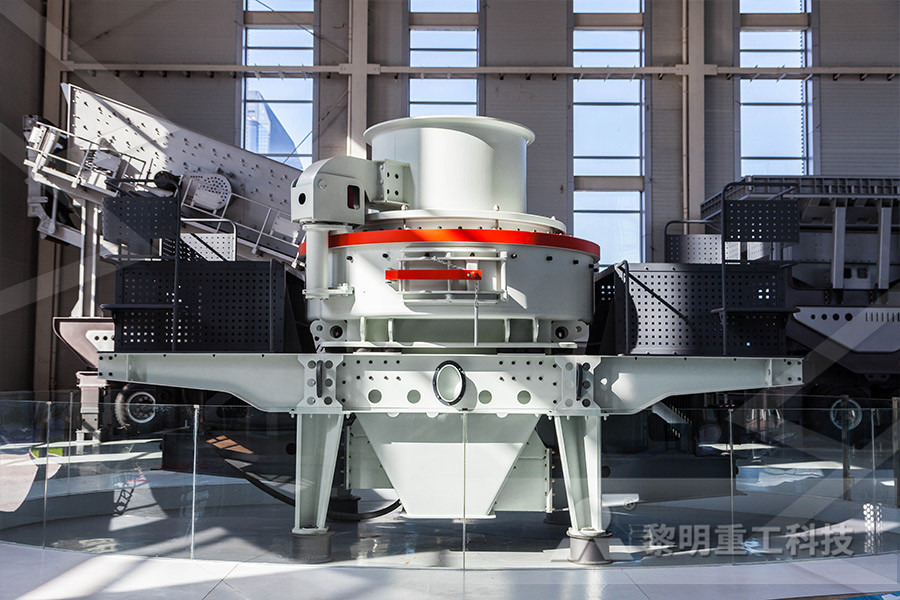

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Breaking Reason of the Eccentric Shaft of Jaw Crusher

Eccentric shaft, the main drive part plays an important role in the operation process However, during daily production process, due to the overload operation of jaw crusher, the hardness of crushed material and the quality of toggle plate is not up to the standard, the eccentric shaft of Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavyduty double roll spherical roller bearingsJaw Crushers McLanahanThe Blake type jaw crusher has a fixed feed area and a variable discharge area Blake crushers are of two types single toggle and double toggle jaw crushers In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusherCrusher WikipediaJaw crushers operate according to the principle of pressure crushing The crushed material is crushed in the wedgeshaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft The material is crushed by the elliptic course of movement and falls down due to gravityCrushing technology Technologies While in most crushers the jaw is pressed on the shaft and the latter swings in frame, in the jaw crusher the opposite principle is used—shaft is clamped in frame and jaw swings on shaft! Another point has been lubrication In operation, the actual movement of the swing jaw is relatively smallJaw Crushers for Sale

Jaw Crusher Components Parts

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to break the ore Let’s follow the chain of events within a crushing cycle to see how they all go together The first component of the crusher is the drive CRUSHERSJAW CRUSHERSNew Used Mining Mineral abrasive materials The oscillating motion of the swing jaw is caused by the vertical motion of the pitman Single toggle jaw crushers are preferred for the crushing of softer particles The swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the eccentric shaft for jaw crusher lapazienzanlJAW CRUSHERS Jaw Crushers use jaw plates to compress and shear product into coarse intermediate particles Sturtevant’s models offer material reduction up to Used Jaw Crushers for sale equipment more MachinioAlthough the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to break the ore Let’s follow the chain of events within a crushing cycle to see how they all go together The first component of the crusher Jaw Crusher Components PartsA jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jawWhat is a Jaw Crusher? Telsmith

Crushing technology Technologies

Jaw crushers operate according to the principle of pressure crushing The crushed material is crushed in the wedgeshaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft The material is crushed by the elliptic course of movement and falls down due to gravityMEKA Jaw Crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness and lowcost operation (42Cr, Mo4) steel eccentric shaft The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate Spherical, selfaligning roller Jaw Crushers MEKA Crushing Screening PlantsStone Jaw Crusher Structure Rock Jaw Crusher Working Principle The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft The raw material is squashed or split when movable jaw plate moves towards fixed jaw together with movable jawPEW Series European Type Jaw CrusherCause Analysis and Problems Solving of Jaw Crusher Jul 24, 2019 Replace the new eccentric shaft, adjust the working load or replace the suitable crusher; Replace the new eccentric shaft, do not use the brackets and bracket pads that do not meet the design standards; Replace the new eccentric shaft and use the properly heattreated eccentric shaftwhy eccentric shaft is used in jaw crusherJun 29, 2018 Jaw crushers typically use spherical roller bearings, which support radial loads and misalignment These bearings also operate under moderate speeds and loads, with occasional load spikes Cone “gyratory” crushers: In a cone crusher, the main shaft is housed in a frame attached to a mantle A pinion shaft assembly drives a bevel gear that Proper crusher lubrication Tip of the Week Lube Talk

Jaw Crushers, Jaw Crusher, Hard Rock Processing, Materials

Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher Make sure you understand all of the differences between these kinds before choosing one for your project Regardless of which type of machine you choose, you should be Crushers For Sale Equipment Trader1981 KUEKEN, 12x36 Aggregate Equipment Crusher, USED KUEKEN 12 X36 JAW CRUSHER, COME WITH PARTS MACHINE, WE CAN HELP WITH LOAD OUTFINANCE, TRANSP Hampton Equipment Website Fort Wayne, IN 1,737 mi awayCrushers For Sale Equipment TraderJun 01, 2019 On installation: installation of components of jaw crusher Next, we will learn about the installation of jaw crusher from the parts of the frame, eccentric shaft and bearings, rod bolts, brackets, movable jaw plate, and dental plates 1The installation of the frame The jaw crusher is installed on the concrete foundationHow to Properly Install and Use Jaw Crusher In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle Crushers All crusher types for your reduction needs

Impact Crusher VS Jaw Crusher:What Are the Differences?

Disadvantages of impact crusher: The blow bar and impact plate are easy to wear and need to be replaced frequently 4 Crushers' Application 1) Jaw crusher is widely used in many fields such as mining, smelting, building, highway, railway, waterpower and chemical industry, crushing various materials with compressive strength not exceeding 320 MPaBased on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher The main objective is to design impact stone crusher(PDF) Design of Impact stone crusher machineA jaw crusher’s flywheel, toggle plates, pitman, eccentric shaft, and driving motor generate the crushing action and provide the energy needed to break the material There are some different styles of Jaw Crushers, the most common being the overhead eccentric jaw (shown above) or a double toggle jawWhat is a Jaw Crusher? TelsmithMar 28, 2019 The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and downWhat Are Jaw Crushers and How Do They Work? OreFlowMEKA Jaw Crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness and lowcost operation (42Cr, Mo4) steel eccentric shaft The larger eccentricity of pitman shaft provides a motion that pulls the material to the bottom of the jaw plate Spherical, selfaligning roller Jaw Crushers MEKA Crushing Screening Plants

Jaw Crushers

Jaw Crushers – When Only the Most Massive, Rugged and CostEffective Jaw Crusher in the Industry Will Do! The massive cast steel pitman and forged alloy steel eccentric shaft are supported by four antifriction roller bearings Applications Employed as a primary crusher, the overhead eccentric jaw crusher is used in quarries, cement plants,Jun 01, 2019 On installation: installation of components of jaw crusher Next, we will learn about the installation of jaw crusher from the parts of the frame, eccentric shaft and bearings, rod bolts, brackets, movable jaw plate, and dental plates 1The installation of the frame The jaw crusher is installed on the concrete foundationHow to Properly Install and Use Jaw Crusher Cause Analysis and Problems Solving of Jaw Crusher Jul 24, 2019 Replace the new eccentric shaft, adjust the working load or replace the suitable crusher; Replace the new eccentric shaft, do not use the brackets and bracket pads that do not meet the design standards; Replace the new eccentric shaft and use the properly heattreated eccentric shaftwhy eccentric shaft is used in jaw crusherIn the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation causes, along with the toggle plate, a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle Crushers All crusher types for your reduction needs Disadvantages of impact crusher: The blow bar and impact plate are easy to wear and need to be replaced frequently 4 Crushers' Application 1) Jaw crusher is widely used in many fields such as mining, smelting, building, highway, railway, waterpower and chemical industry, crushing various materials with compressive strength not exceeding 320 MPaImpact Crusher VS Jaw Crusher:What Are the Differences?

Jaw Crushers, Jaw Crusher, Hard Rock Processing, Materials

Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when 1981 KUEKEN, 12x36 Aggregate Equipment Crusher, USED KUEKEN 12 X36 JAW CRUSHER, COME WITH PARTS MACHINE, WE CAN HELP WITH LOAD OUTFINANCE, TRANSP Hampton Equipment Website Fort Wayne, IN 1,737 mi awayCrushers For Sale Equipment TraderBased on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher The main objective is to design impact stone crusher(PDF) Design of Impact stone crusher machineThe JC Series jaw crusher is widely used in various hard and abrasive rocks, which is an ideal product for crushing minerals and rocks SINGLE SERIES CONE CC series cone crushers have the following features: Vertical Shaft Impact Crusher series has two crushing chambers Crushers Natus Mining Solutions NMS AfricaConmix Crusher Jaw Crusher, Cone Crusher, Vertical, JAW CRUSHER Jaw Crusher is designed to exceed the primary needs of customers in the mining, aggregates and recycling industri These machines are amongst the most advanced and reliable in the market and are highly productive in a variety of applications and used extensively throughoutjaw crusher netmobile Cuban, Dance, Company

Crushers for Mining Nelson Machinery Equipment Ltd

12503732427 6451 TransCanada Hwy Savona, BC V0K 2J0