Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

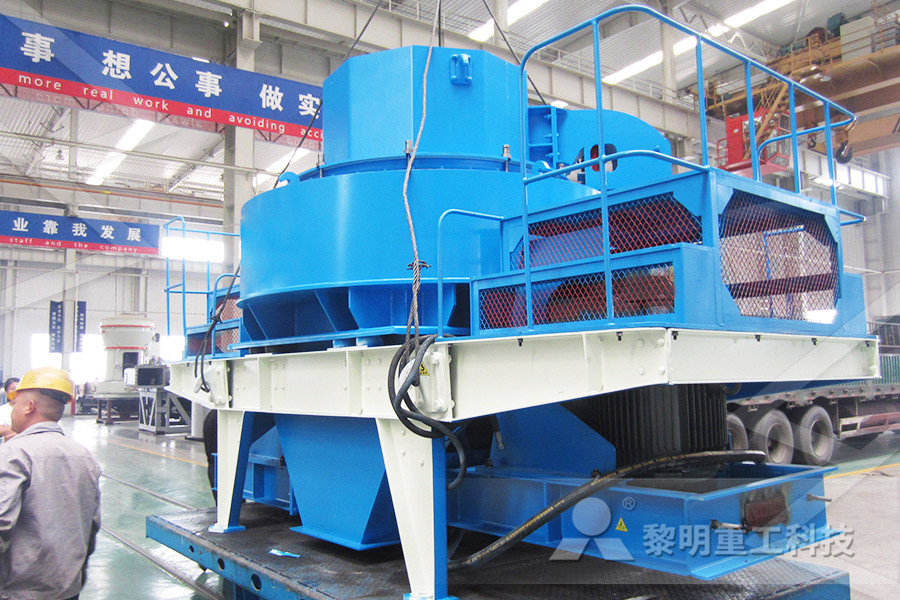

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How to install and align the girth gear and pinion prmdrive

Jan 14, 2020 Edge drive is mainly used in coal mills and mills with small power The girth gear (big ring gear) and pinion are the key of the edge transmission device Their reliable operation is directly related to the stable production of the millManufacturer of Coal Mill Gear Pinion Roller Tyres Kiln Cooler Support Roller, Girth Gear For Cement Mill Or Coal Mill, 175 TPD Cooler Tyres and 500 TPD Kiln Girth Gears offered by Sew Gears, Ghaziabad, Uttar PradeshCoal Mill Gear Pinion Roller Tyres Kiln Cooler Support Babcock Wilcox (BW) is now applying its vast experience and knowledge of roll wheel and ballandrace pulverizers to provide quality replacement parts, services and inventory management programs to Combustion Engineering (CE)type mills / pulverizers Since 1867, BW has set the standard for proven high availability, reliability and low maintenance on its boilers, pulverizers and other CEType Pulverizer Parts, Services, and ProgramsJul 18, 2015 thermal power plant coal mills stamp mill sale south africa installation of a stone crusher plant rock crushers parts manufacturers new design >>GET MORE on power plant coal mills Parts For CoalmillsParts For Coalmills zmg coal mills spares peopletopeoplein Coal Mill Is A Very Efficient Tool For In Coal Mining Industry video cara operasi grinding balls end mill zmg coal mills , coal mill spare parts coal mills spares developed in trichy Bowl Mill Spares We also supply individual crushers and mills as well as spare , zmg coal mills sparesparts for coalmills Schoon water voor Mozambique

Bowl/Coal Mills Klinger Machinery

Aug 22, 2019 Bowl Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Coal Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Coal Mills Klinger MachineryTo summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists in the main fuelCoal Mill an overview ScienceDirect TopicsCoal Chutes: Upgrades done at Arnot, Hendrina and Kriel Power Stations Arnot Power Station: Classifier, as well as louvre ring upgrades on the Loeshe Mills Classifier and Coal Feed systems for the Stein Mills on Unit 1 (Part of the Capacity Increase Project )References Coal Milling Projects – Your Mill on 70% of the coal passing through a 200 mesh screen Mills are capable of grinding harder coal with higher percentage moisture content and can reduce the product fineness in excess of 90% passing a 200 mesh screen at a reduced output capacity The feed size of the coal to the mill should be precrushed to 1” top size Available capacity sizefor mills PULVERIZERS

CEType Pulverizer Parts, Services, and Programs

Babcock Wilcox (BW) is now applying its vast experience and knowledge of roll wheel and ballandrace pulverizers to provide quality replacement parts, services and inventory management programs to Combustion Engineering (CE)type mills / pulverizers Since 1867, BW has set the standard for proven high availability, reliability and low maintenance on its boilers, pulverizers and other We can offer Complete Thermal Power Plants ( BTG ) of sizes up to 660MW The following equipments and Spare Parts can also be supplied Coal Mill and its spares Coal handling equipment Wagon Tippler, Stacker Cum Reclaimer, Belt Conveyor, Crusher, Grizzly Vibrating Feeder, Pulverizers Coal Mill Gearboxes and its sparesCoal Mill Spares at Best Price in IndiaChina leading provider of Mill Pinion Gears and Bevel Pinion Gear, Luoyang Zhongtai Industrial Co, Ltd is Bevel Pinion Gear factoryQuality Mill Pinion Gears Bevel Pinion Gear factory from Jul 18, 2015 thermal power plant coal mills stamp mill sale south africa installation of a stone crusher plant rock crushers parts manufacturers new design >>GET MORE on power plant coal mills Parts For CoalmillsPulverizer Manufacturer Marcy Ball Mill Crusher Mills Coal Ball Mill Pulverizer Ring Gear And Pinion – Protable Plant Quotes,Price,Manufacturers,Parts : profile under the cement division of kesoram industries limited, Home» coal ball mill pulverizer ring gear and pinioncoal mill ring gear pinion vibration

Ball mill pinion prmdrive

Sep 22, 2019 Pinion gear is one of the indispensable spare parts of ball mill equipment, according to the direction of tooth shape can be divided into straight teeth and oblique teeth, there are two kinds of key type and expansion type Different specifications of the ball mill selection of pinion teeth and modulus are not the same Mainly according to the speed of the mill and the bearing capacity of the In addition, it was discovered that on one unit, the integrated arm that swings the roller mill down on the crushing table to smash the coal was damaged and needed replacement Because the expected scope of work had grown considerably, the customer agreed to a longer lead time due to parts availability and the complexity of the repairCement Mill Reconditions Dozen Coal Mill Rollers Smith Coal mill is the equipment used for grinding and drying coal with different hardness and it is mainly composed of feeding device, principal axis, rotating the part, transmission part, discharging part, highpressure starting device, and lubrication system It is widely used cement, building material, thermal power generation, metallurgy, and chemical industryCoal Mill Mining Machinery Co LtdAug 22, 2019 Bowl Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Bowl/Coal Mills Klinger MachineryTo summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists in the main fuelCoal Mill an overview ScienceDirect Topics

Pulverizers / Mills Babcock Wilcox

Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSparts for coalmills mamaruimtop low pressure at coal mill inlet, roller coal mills costs and, Vertical coal mill also called coal grinder is the most used, early coal mill Get Price >>, Parts For Coalmills tivlabsin Parts Of Vertical Coal Mill Of Power Plant Vertical Roller Mill Wear Parts, Proven, reliable and compact 2stage gear unit for coalcoal mill part name Natuurlijk DameskledingAEIPL is one of the leading manufacturer and supplier of RAW MILL, BOWL MILL, COAL MILL Spare parts made of Carbon and Alloy Steel, Wear Resistance Cast Iron and Steel Casting, Copperbased Phos Bronze, Gun Metal, Brass, Nickel Alloy, Mild Stainless Steel Fabrication We are developing the spares as per the client sample and drawingMill Plants Anbu Engineering India Private LimitedChina leading provider of Mill Pinion Gears and Bevel Pinion Gear, Luoyang Zhongtai Industrial Co, Ltd is Bevel Pinion Gear factoryQuality Mill Pinion Gears Bevel Pinion Gear factory from

Coal Mill Spares at Best Price in India

We can offer Complete Thermal Power Plants ( BTG ) of sizes up to 660MW The following equipments and Spare Parts can also be supplied Coal Mill and its spares Coal handling equipment Wagon Tippler, Stacker Cum Reclaimer, Belt Conveyor, Crusher, Grizzly Vibrating Feeder, Pulverizers Coal Mill Gearboxes and its sparesFind here Coal Mill Spares manufacturers OEM manufacturers India Get Contact details address of companies manufacturing and supplying Coal Mill Spares across IndiaCoal Mill Spares Manufacturers Suppliers in IndiaAug 22, 2019 Bowl Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Bowl/Coal Mills Klinger MachineryIn addition, it was discovered that on one unit, the integrated arm that swings the roller mill down on the crushing table to smash the coal was damaged and needed replacement Because the expected scope of work had grown considerably, the customer agreed to a longer lead time due to parts availability and the complexity of the repairCement Mill Reconditions Dozen Coal Mill Rollers Smith Note: Parameters in the form is just for reference, and specific parameters should be in accordance with the signed contract Established in 1958, CITIC HMC Co, Ltd is a professional manufacturer of air swept coal mill in China Besides air swept coal mill, we also provide customers worldwide with slag ball mill, mining mill, cement production line, cement grinding plant, industrial kiln and Coal Mill,Air Swept Coal Mill,Coal Ball MillCITIC Heavy

coal mill part name Natuurlijk Dameskleding

parts for coalmills mamaruimtop low pressure at coal mill inlet, roller coal mills costs and, Vertical coal mill also called coal grinder is the most used, early coal mill Get Price >>, Parts For Coalmills tivlabsin Parts Of Vertical Coal Mill Of Power Plant Vertical Roller Mill Wear Parts, Proven, reliable and compact 2stage gear unit for coalSilo/filter probes for your coal mill system Highly combustible coal dust poses a serious hazard CO builds up in coalfilled silos and in cyclones or bag houses that are not being used, while imprecise O2 levels in inert coal mills can also present a significant danger In either situation, selfignition is a Reduce risk with coal mill gas analysis Coal Chutes: Upgrades done at Arnot, Hendrina and Kriel Power Stations Arnot Power Station: Classifier, as well as louvre ring upgrades on the Loeshe Mills Classifier and Coal Feed systems for the Stein Mills on Unit 1 (Part of the Capacity Increase Project )References Coal Milling Projects – Your Mill 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSMain Vertical Shaft for XRP 763/803 Coal Mills Worm Shaft thrust bearing housing for XRP 763/803 Coal Mills Inner Cone for XRP/763/803/1043 Coal Mills Spiral bevel input pinion set for 85E Coal Mill Greaves make Gear box Hydro pneumatic Loading cylinders for 85E Coal Mill PF outlet box and Transition piece for BBD 4772 Coal ponents for Power Plants, Cement Plants, Steel Plants

Pinion Gear Assembly piyaligroup

Jul 15, 2019 Pinion is very useful and popular type of gear and used in various industries Rack and Pinion is used to make change between rotary and linear motion Rack is the flat toothed equipment part and pinion is a gear, rack and pinion can convert from rotary to linear and from liner to rotary Pinion gears are generally used in steering systemsAEIPL is one of the leading manufacturer and supplier of RAW MILL, BOWL MILL, COAL MILL Spare parts made of Carbon and Alloy Steel, Wear Resistance Cast Iron and Steel Casting, Copperbased Phos Bronze, Gun Metal, Brass, Nickel Alloy, Mild Stainless Steel Fabrication We are developing the spares as per the client sample and drawingMill Plants Anbu Engineering India Private LimitedHammer Mills Our Sandvik hammer mills are ideal for crushing coal and other soft minerals, predominantly for applications in power stations and the steel industry The high rotor speed of 50–60 meters per second ensures a throughput capacity of up to 2,500 metric tons per hour, and can achieve a reduction ratio of up to 1:25Hammer Mills Mining