Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

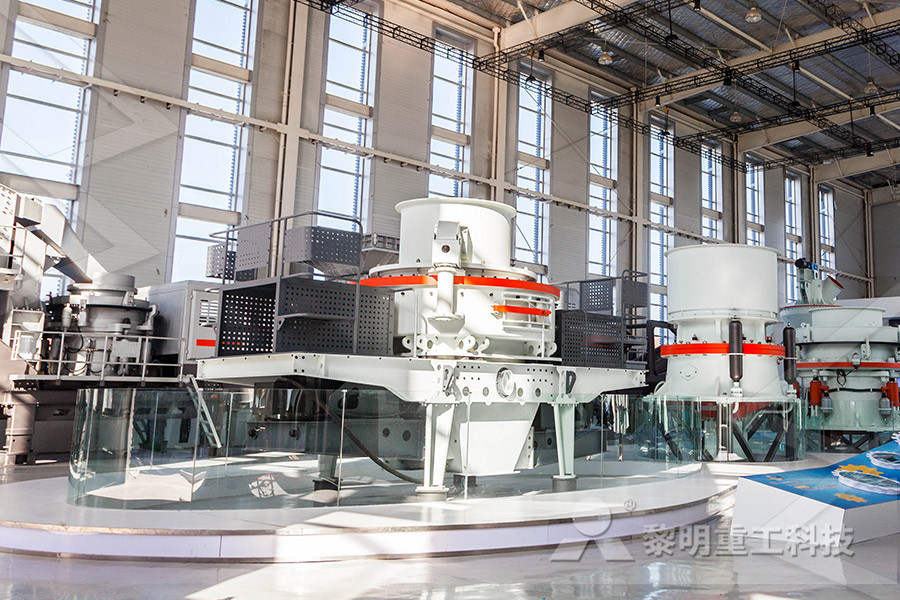

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Sierra Pin mill NETZSCH Grinding Dispersing

As standard, the mill body is a robust, welded mild steel construction Access on the Sierra mill is excellent and pin replacement is an easy operation procedure The Sierra mill also represents an economical and highly efficient method of coating ultrafine fillers with stearic acidWhere necessary, the SIERRA pin mill can also be offered in stainlesssteel construction Access on the SIERRA mill is excellent and pin replacement is an easy operation The SIERRA mill also represents an economical and highly efficient method of coating ultrafine fillers with stearic acidSIERRA Pin Mill for fine products and coatingpin mill coating stearic acid As standard the mill body is a robust welded mild steel construction Access on the Sierra mill is excellent and pin replacement is an easy operation The Sierra mill also represents an economical and highly efficient method of coating ultrafine fillers with stearic acidpin mill coating stearic acid Hitlers HollywoodStearic acid) is predominantly used as a coating agent We have developed 3 different continuous surface treatment systems/ coating systems on the base of successful experience of Hosokawa Alpine and Omya Group, pin mill coating machine, turbo mill coating machine, hammer mill coating machinepin mill coating stearic acid chaletdegroupechpin mill coating stearic acid Stearic Acid Coating on Calcium Carbonate pin mill coating stearic acid 6681,Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final product quality Grinding Pin AcidCitrid Acid stearic acid coating plant for caco3

ECoat System NETZSCH Grinding Dispersing

The most common use of this system is to coat CaCO3 with stearic acid By coating fine ground and classified Calcium Carbonate, we can add more value to fillers in the fineness range of 3µm to 45µm The plastic industry requires this type of coated filler for many applicationsJan 13, 2012 ECUTEC Coating Systems utilize a Pin Mill with high shear forces to achieve the best deagglomerating action Simultaneously CaCO3 and stearic acid are added into a highly turbulent area which is the key to a perfectly coated product with a very low consumption of stearic acid (05% and 1%, depending on product fineness)New Coating System Ecutec Technical BlogPin Mill Coating Machine Normally, this type is very popular in European and American markets Two rotors running in opposite direction, their linear speed can be up to 200m/s The modifier can be selected from stearic acid or a coupling agent (titanate coupling agent, aluminate coupling agent, phosphate coupling agent, etc)powder coating and surface modification production line Alpine Contraplex Pin Mills typically deliver high grinding fineness in the range 10 – 500µm, especially with brittle and crystalline materials The following industry areas are relevant for Contraplex mills: Minerals powders: calcium carbonate, fillers, calcium hydroxide Coating of fillers with stearic acidContraplex Pin Mills, C CW Hosokawa Micron LtdMill Coating Stearic Acid Aug 19, stearic acid coating on calcium carbonate Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final stearic acid coating machine, stearic Carbonate Stearic Coating Plant

pin mill coating stearic acid Hitlers Hollywood

pin mill coating stearic acid As standard the mill body is a robust welded mild steel construction Access on the Sierra mill is excellent and pin replacement is an easy operation The Sierra mill also represents an economical and highly efficient method of coating ultrafine fillers with stearic acidWhere necessary, the SMW pin mill can also be offered in stainlesssteel construction Access on the SMW mill is excellent and pin replacement is an easy operation The SMW mill also represents an economical and highly efficient method of coating ultrafine fillers with stearic acid Features 1 Fine grinding of soft and medium hard minerals 2SIERRA Pin Mill for fine products and coatingStearic acid) is predominantly used as a coating agent We have developed 3 different continuous surface treatment systems/ coating systems on the base of successful experience of Hosokawa Alpine and Omya Group, pin mill coating machine, turbo mill coating machine, hammer mill coating machineParticle Surface Coating MachinesParticle Surface Coating Pin Mill Coating Machine Normally, this type is very popular in European and American markets Two rotors running in opposite direction, their linear speed can be up to 200m/s The modifier can be selected from stearic acid or a coupling agent (titanate coupling agent, aluminate coupling agent, phosphate coupling agent, etc)powder coating and surface modification production line Limestone Powder Surface Coating Machine With Pin Mill Rotor Mill Turbo Mill , Find Complete Details about Limestone Powder Surface Coating Machine With Pin Mill Rotor Mill Turbo Mill,Surface Coating Machine,Limestone Powder Surface Coating Machine,Curved Surface Coating Machine from Mine Mill Supplier or ManufacturerQingdao Epic Powder Machinery Co, LtdLimestone Powder Surface Coating Machine With Pin Mill

Ground Calcium Carbonate / Limestone Mineral

For plastic fillers, stearic acid coating on ground calcium carbonate is often performed Very uniform coatings are produced using Hosokawa Alpine’s Contraplex (CW) pin mill coating system or Mikro LGM Long Gap Mill for flash drying and coating at the same timeWe have developed 3 different continuous surface treatment systems/ coating systems on the base of successful experience of Hosokawa Alpine and Omya Group, pin mill coating machine, turbo mill coating machine, rotor mill coating machine Our Services 1Advanced Powder Surface Coating Powder Grinding MillAlpine Contraplex Pin Mills typically deliver high grinding fineness in the range 10 – 500µm, especially with brittle and crystalline materials The following industry areas are relevant for Contraplex mills: Minerals powders: calcium carbonate, fillers, calcium hydroxide Coating of fillers with stearic acidContraplex Pin Mills, C CW Hosokawa Micron LtdAug 19, 2009 stearic acid coating on calcium carbonate Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final stearic acid coating machine, stearic acid coating machineCalcium Carbonate Stearic Acid Coating MachineMill Coating Stearic Acid Aug 19, stearic acid coating on calcium carbonate Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final stearic acid coating machine, stearic Carbonate Stearic Coating Plant

Magnesium Hydroxide

Magnesium Hydroxide is a highly efficient nontoxic inorganic flame retardant Perfect choice for production of PA, PP, PE, EVA, etc based compounds pharmaceutical industry (laxatives, antacids and other magnesiumcontaining medicines) food industry as food additive E528 (acidity regulator, color stabilizer etc) production of lubricating oil additives production of magnesium compounds The SIERRA pin mill forms the heart of Ecutec's ECOAT, a unique solution for the coating of ultrafine powders This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industrystearic acid coated calcium carbonate reinforcementThe SIERRA pin mill forms the heart of Ecutec's ECOAT, a unique solution for the coating of ultrafine powders This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industry The SIERRA's proprietary injector design achieves a high degree of atomization of the coating fluid, while the high tip speeds Coating Systems for Calcium Carbonate Preferred Process Natural or synthethic max (eg Stearic acid) is predominantly used as a coating agent We have developed 3 different continuous surface treatment systems/ coating systems on the base of successful experience of Hosokawa Alpine and Omya Group, pin mill coating machine, turbo mill coating machine, rotor mill coating machineContinuous Powder Surface Coating Systems Zinc Oxide Alpine Contraplex Pin Mills typically deliver high grinding fineness in the range 10 – 500µm, especially with brittle and crystalline materials The following industry areas are relevant for Contraplex mills: Minerals powders: calcium carbonate, fillers, calcium hydroxide Coating of fillers with stearic acidContraplex Pin Mills, C CW Hosokawa Micron Ltd

stearic acid coated calcium carbonate reinforcement

The SIERRA pin mill forms the heart of Ecutec's ECOAT, a unique solution for the coating of ultrafine powders This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industryPin Mill Coating Machine Normally, this type is very popular in European and American markets Two rotors running in opposite direction, their linear speed can be up to 200m/s The modifier can be selected from stearic acid or a coupling agent (titanate coupling agent, aluminate coupling agent, phosphate coupling agent, etc)powder coating and surface modification production line Stearic acid) is predominantly used as a coating agent We have developed 3 different continuous surface treatment systems/ coating systems on the base of successful experience of Hosokawa Alpine and Omya Group, pin mill coating machine, turbo mill coating machine, hammer mill coating machineParticle Surface Coating MachinesParticle Surface Coating The calcite coating process consists of three main stages The first of these is the stearic acid melting unit, the second is the micronized calcite feeding unit and the third is the pin mill unit in which the micronized calcite and melted stearic acid are mixed together and the coating process takes placeAPPLICABILITY OF STATISTICAL PROCESS CONTROL FOR GCC as an additive in almost all polymers must be subjected to a surface treatment, known as coating by means of technical stearic acid Ultrafine Calcium Carbonate and perfect coating the plastics industry achieves the highest quality available in the market by coating in a fully optimized Contraplex pin mill system with feed powder Calcium Carbonat (GCC) Hosokawa Alpine

Coating System for Functional Fillers Ecutec Technical Blog

Aug 09, 2013 With high temperatures in the ductwork for conveying the particles to the silo or bagging area, there is the risk of the particles agglomerating because the stearic acid remains sticky In some coating systems, the full coating cannot take place in the mill and following conveying lines are kept hot to allow for some further coating activity to Mill Coating Stearic Acid Aug 19, stearic acid coating on calcium carbonate Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final stearic acid coating machine, stearic Carbonate Stearic Coating PlantAug 19, 2009 stearic acid coating on calcium carbonate Dear Saurabh, The most effective way to coat GCC with stearic acid is to use an Ecutec coating plant on basis of our pinmill with a stearic acid injector This will safe a lot of energy, acid and you will have a top final stearic acid coating machine, stearic acid coating machineCalcium Carbonate Stearic Acid Coating MachineThe SIERRA pin mill forms the heart of Ecutec's ECOAT, a unique solution for the coating of ultrafine powders This system is most commonly used for coating calcium carbonate with stearic acid to meet the requirements for fillers used in the plastics industryCalcium Carbonate Coating Plant YoutubeWhether as a sieveless pin mill with a rotating and a fixed pin disk, as a beater mill with a fixed disk of rigid hammers or a pendulum hammer disk, there are numerous practiceoriented combinations of grinding tools calcium carbonate, fillers, calcium hydroxide Coating of fillers with stearic acid, silane, etc • Food: fatty proteins Continuum Technology Impact Mill CIM

Coated Calcium Carbonate, Powder, Packaging Size: 50 Kg

Coated Calcium Carbonate is produced by coating the surface of uncoated GCC This coating process is done with the help of pin mill and a stearic acid injector The Surface coating treatment changes the alkalinity of uncoated GCC The coated GCC is extensively used in PVC industries to make smooth surface, better flow, high filler loadingAdvantages: mature technology, low investment, suitable for coating of stearic acid; selffriction heat generation, less auxiliary equipment; suitable for coating of 325~1250 mesh powder CTurbo Mill (tower mill) continuous coating processPowder Coating Production Line – ALPA Powder TechnologyPGT Project Closure for UltraFine Calcium Carbonate Coating Line أكتوبر 2019 ديسمبر 2019 Ball mill with classifying systems to cover a wide capacity and fineness range of d97 = 5 45 μm with pin mill to coating by stearic acidFouad Ghoneim, PMP®, SSYB™, IOSH® Projects Manager