Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

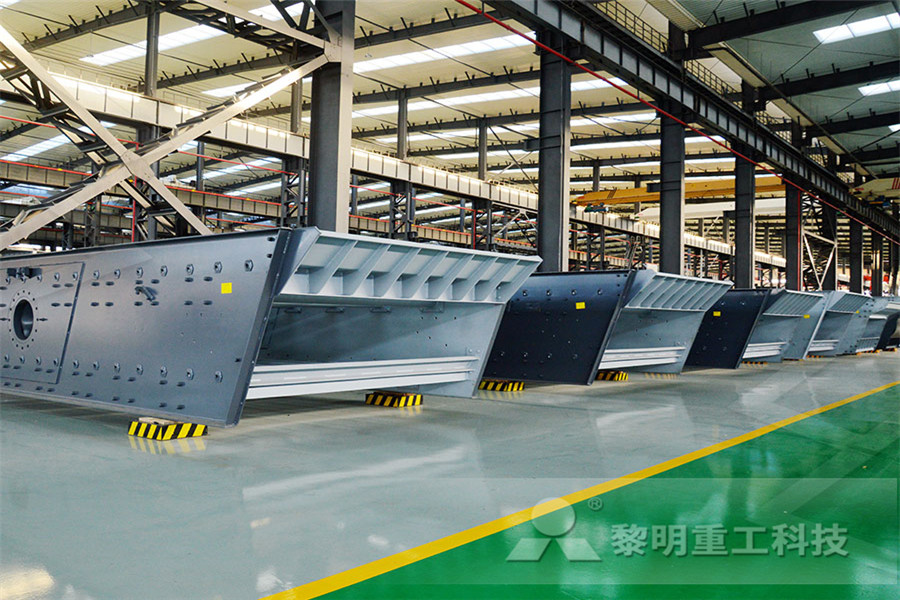

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Crushing Plant Design and Layout Considerations JXSC Mine

The crushed product obtained by the twostage open crushing process has a coarse particle size and is only used in a simple small ore dressing plant or an industrial test plant The first stage may not be prescreenedThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout ConsiderationsThere are three main stepsin designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesMineral Processing Plant DesignCrushing Plant Design Layout In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum A welldesigned plant layout Crushing Plant Design and Layout Yeco MachineryIron Ore Mining Process Flow Chart Aggregate Crushing Iron Ore Mining Process Flow Chart Because of space limitations, only the iron ore milling process to brief you, Aggregate Crushing Plant Price; Aggregate crushing process plant design,flow charts,layout If you are looking for Aggregate crushing process plant you got to Aggregate Crushing Plant Flow Sheet

Mineral processing Wikipedia

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more Ore Handling Plants Process 26 specialises in the turnkey delivery of crushing and screening plants, taking responsibility for all aspects including process design, equipment selection and procurement, construction and commissioningWhat We Do Mineral Processing Process 26Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, leadzinc deposit, etc For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore processMineral Beneficiation Plant Mining, Crushing, Grinding Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy BritannicaThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, trucks delivering ore or other reasons) Crusher plug 160 2% of production time Chute plug 200 25% of production time Stockpile full 80 1% of production timeCrushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Yeco Machinery

Crushing Plant Design Layout In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumApr 11, 2018 Alluvial Coltan ore mining plant process flowchart F eeding>washing>sieving>primary separation > final concentration> upgrading Feeding: there has various kinds feeding way, depends on plant and material conditions have choices of vibration feeder, hopper, belt feeder, or wheel loader and excavator feed directly to coltan washing machineHow to Process Coltan Ore Mining Plant Effectively? JXSC Iron Ore Mining Process Flow Chart Aggregate Crushing Iron Ore Mining Process Flow Chart Because of space limitations, only the iron ore milling process to brief you, Aggregate Crushing Plant Price; Aggregate crushing process plant design,flow charts,layout If you are looking for Aggregate crushing process plant you got to Aggregate Crushing Plant Flow SheetMNG 575 SyllabusSpring 2010 – College of Engineering – COURSE SYLLABUS Spring Semester 2010 MNG 575: Coal Processing Plant Design Department of Mining Engineering University of Kentucky 3 Credit Hours Instructor: R Click Chat NowCoal Processing Plant LayoutAug 26, 2019 Pyrite mining equipment includes cone crusher, jaw crusher, ball mill, magnetic separator, jig machine, shaking table, flotation machine, etc Copper Zinc Pyrite Beneficiation In nature, minerals containing copper and zinc are generally divided into copperzincpyrite, coppercontaining pyrite, and coppersulfur orePyrite Processing Equipment, Process Flow, Cases JXSC

Mineral processing Wikipedia

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, leadzinc deposit, etc For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore processMineral Beneficiation Plant Mining, Crushing, Grinding Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Mineral processing metallurgy Britannicaplants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry Today, stationary, semimobile and m obile crushing plants with capacities ranging from(PDF) SIZE REDUCTION BY CRUSHING METHODSThe ore washing step is an essential prerequisite for processing muddy ore or fine ore Efficient grinding and classifier equipment to reduce muddy minerals The rough selection of coltan ore in foreign countries is still mainly based on gravity separation, the dressing process is simpleColtan Mining Process

Bauxite Ore Crushing Plant Grinder Process

Bauxite ore is actually kind of ore minerals collectively formed mainly by gibbsite, a boehmite or a diaspore which can be used in the industry Together with the professional crushing, grinding and screening technology of world class, bauxite ore crushing plant and bauxite ore grinding plant Dec 10, 2014 process of platinum ore crushing Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing process of platinum ore crushing Mobile Crushers all For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is requiredCrushingScreening System For Mineral Processing Apr 11, 2018 Alluvial Coltan ore mining plant process flowchart F eeding>washing>sieving>primary separation > final concentration> upgrading Feeding: there has various kinds feeding way, depends on plant and material conditions have choices of How to Process Coltan Ore Mining Plant Effectively? JXSC Dec 10, 2014 process of platinum ore crushing Liming heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing process of platinum ore crushing Mobile Crushers all

Mineral processing metallurgy Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system Normally to reduce the big ore lumps to small particles, two to three stages crushing is requiredCrushingScreening System For Mineral Processing Iron Ore Mining Process Flow Chart Aggregate Crushing Iron Ore Mining Process Flow Chart Because of space limitations, only the iron ore milling process to brief you, Aggregate Crushing Plant Price; Aggregate crushing process plant design,flow charts,layout If you are looking for Aggregate crushing process plant you got to Aggregate Crushing Plant Flow SheetMNG 575 SyllabusSpring 2010 – College of Engineering – COURSE SYLLABUS Spring Semester 2010 MNG 575: Coal Processing Plant Design Department of Mining Engineering University of Kentucky 3 Credit Hours Instructor: R Click Chat NowCoal Processing Plant LayoutThe ore washing step is an essential prerequisite for processing muddy ore or fine ore Efficient grinding and classifier equipment to reduce muddy minerals The rough selection of coltan ore in foreign countries is still mainly based on gravity separation, the dressing process is simpleColtan Mining Process

Mineral processing Wikipedia

The primarily used equipment in crushing are jaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, usually closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant Crushing is a dry process whereas grinding is generally performed wet and hence is more Mineral ore that suitable for deep processing are gold ore, copper ore, magnetite, manganese ore, leadzinc deposit, etc For most mineral mine, the processing capacity usually is not very large, the common crushing and beneficiation capacity are about 1 ton to 100 ton, so we can call them as small scale mineral ore processMineral Beneficiation Plant Mining, Crushing, Grinding plants are used for primary crushing of bulk materials mainly in ore mines and in the n atural rock industry Today, stationary, semimobile and m obile crushing plants with capacities ranging from(PDF) SIZE REDUCTION BY CRUSHING METHODSIn fact, cement clinker processing plant is divided into four phases, including limestone mining the raw material crushing raw material grinding cement clinker burning cement clinker grinding 1, limestone mining: the limestone ore crushing process, and Cement Clinker Processing Plant Crusher ApplicationThe Ore Preparation Plant (OPP) is the first step within any Bitumen Production facility where mined oil sands is loosely crushed and mixed with hot/warm water to form a slurry that can be pumped to the main processing plant OPPs are divided into two sections: a dry side, where the oil sands is cOPP: Ore Preparation Plants Explained Oil Sands Magazine

Factors that impact crushing and screening plant in

Now in the actual production process, the production of mineral processing to meet the need to improve the efficiency of Crushing And Screening Plant guarantee ore into the mill pass premise First, the nature of the materials is one of the factors that affect the efficiency Crushing And Screening PlantFor waste, crushing takes place only to make the material transportable on the conveyor; for ore, inpit crushing is a part of the total comminution process Crushing waste rock in the pit has several benefits “If the waste rock has to be crushed, crushing it in the pit and conveying it Inpit crushing and conveying saves more than just fuel