Solutions

Products

-

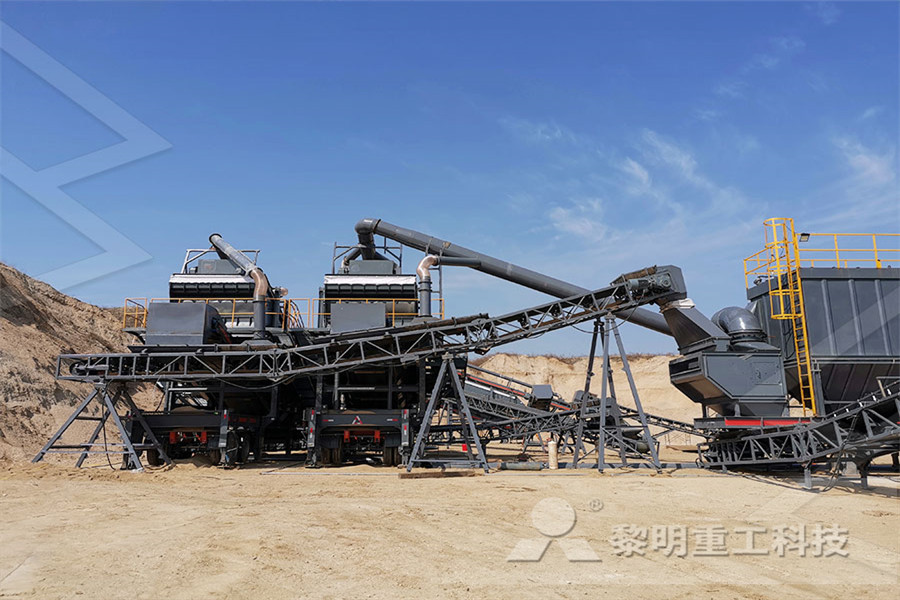

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

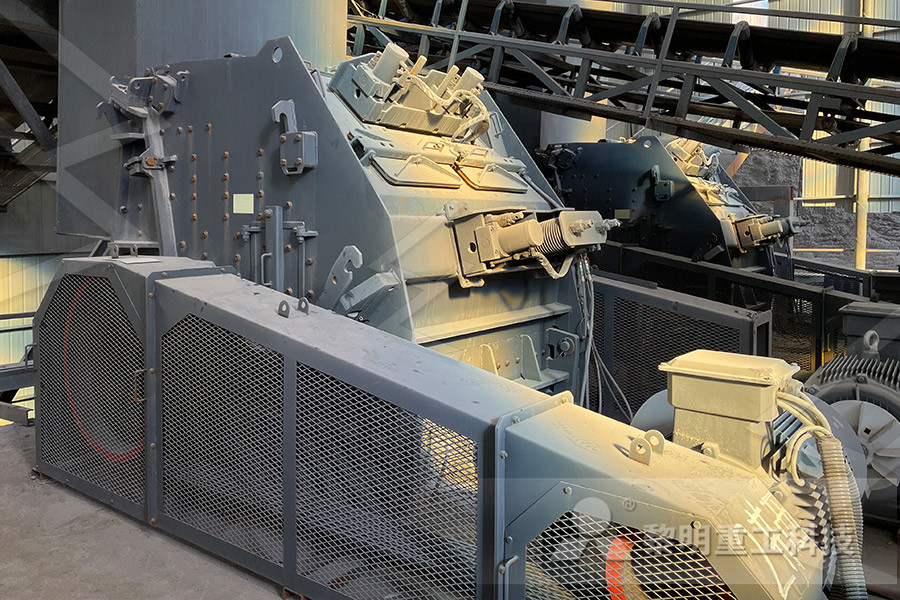

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

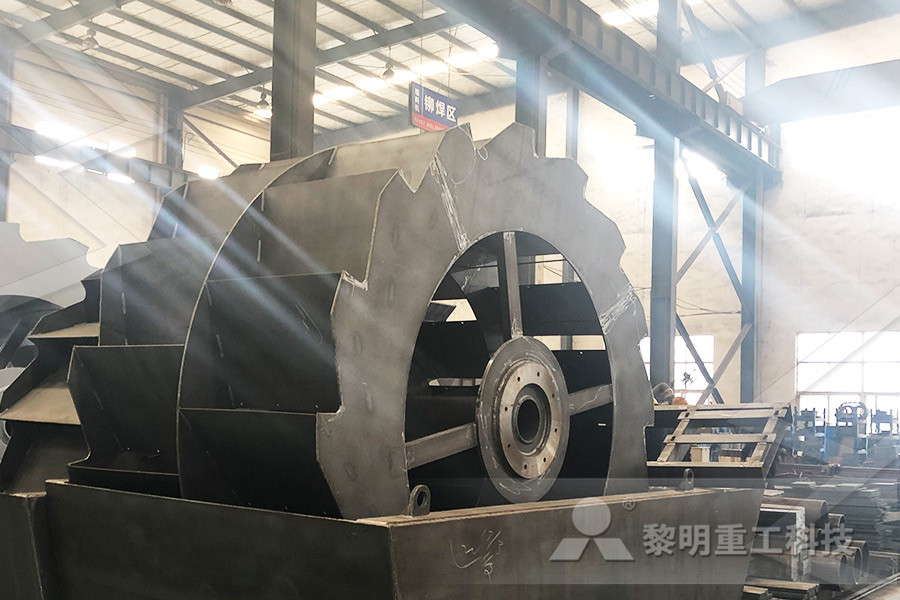

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

(PDF) Performance Evaluation of Vertical Roller Mill in

Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedThe world’s largest vertical roller mill at a cement plant – as certified by Guinness World Records – has completed performance guarantee testing, after operating successfully at Shah Cement Recordsetting vertical roller mill exceeds performance Vertical roller mill: good performance and popular Time: Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protectionVertical roller mill: good performance and popularVertical roller mill working principle For roller press, the grinding parts are two rollers of the same size The materials fall vertically from the top to the two rollers to form the material bed Under the extrusion force of the two rollers, materials are ground to fine particlesCement Grinding Machine Selection: Vertical Roller Mill VS Apr 01, 2017 The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance model The model consists of grinding and separation sectionsOperational parameters affecting the vertical roller mill

Ball Mills Or Vertical Roller Mills: Which Is Better For

Operating a ball mill is quite simple as it lacks any moving mechanical parts within the mill The system is quite versatile and is designed to accommodate variation in mill feed quantity and quality On the other hand, the vertical roller mills (VRM) is quite a complicated and sophisticated equipment with hydraulics that controls the rollersThe vertical mill is energy efficient with low specific wear rate Vertical mill supports drying of the feed material, grinding, separating, and material transport inside the mill Vertical mill gives optimum grinding performance when grinding rollers and tables are in good condition, properly aligned and preloaded Vertical Mill Tires and TablesVertical Roller Mill Parts EcorporatesVertical roller mills (VRM) have been utilized in the industry mostly in power plants for coal pulverizing The mill combines crushing, grinding, classification and if necessary drying operationsOperational parameters affecting the vertical roller mill Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grindingOperational parameters affecting the vertical roller mill Improved performance with advanced wear materials in vertical roller mills The cement market in India is continuously growing Rising demands lead to larger and Improved performance with advanced wear materials in

Operational parameters affecting the vertical roller mill

This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm; Production capacity: 3340 tons / hourVertical Roller Mill Structure And Working PrincipleVertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill Vertical mill is a kind of crushing equipment, which is widely used in mining crushing, pulverized coal preparation, chemical industry and other industries Vertical roller mills have been around for many years There are many factors affecting the output of vertical coal mills, but especially The important thing is to control the stability of Factors affecting the Stability of Vertical Roller MillsThe working principle of HLM Vertical Roller Mill The motor drives the reducer to rotate the millstone, the raw material are send into the center of the millstone from the air lock rotary feeder Under the effect of centrifugal force, the material moves to the edge of the millstone Performance advantages: 1 High efficiency (1) Low energy HLM Vertical Roller Mill

Vertical Roller Mill Parts Ecorporates

The vertical mill is energy efficient with low specific wear rate Vertical mill supports drying of the feed material, grinding, separating, and material transport inside the mill Vertical mill gives optimum grinding performance when grinding rollers and tables are in good condition, properly aligned and preloaded Vertical Mill Tires and TablesToday the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, ATOX coal mill Example: Xwin ® application in a cement mill Generally speaking in vertical mills grinding clinker the operation is mainly driven by the fineness of the finish product, meaning that the maximum allowable wear on the grinding rollers is 2530 mmImproved performance with advanced wear materials in Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control This automation solution stabilises the VRM to allow operation with lower vibration It also optimises mill performance by making accurate control actions several times per minute and offers continuous monitoring of the milling circuit for improved operationalFOR VERTICAL ROLLER MILLS LoescheOct 23, 2015 Vertical roller mills are developed to work as airswept grinding mills Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double roller mill, Pfeiffer® MPS mill) Loesche roller mill and Polysius® roller mills are widely applied in cement raw material grindingEnergyEfficient Technologies in Cement Grinding IntechOpen

Vertimill VS Ball Mill Grinding Classification

With regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for shortThere are two different types of vertical mills: Vertical roller mills Such mills normally have intwith critical process parameters to ensure optimum performance and assurance of lifetime Such activities allow Magotteaux to validate designs and further push the boundaries of wear performance For more information on Magotteaux’s complete line of Vertical Roller Mill Castings and on our overall product lineup andCEMENT AND UTILITIES LABLAORTYESTIRERN˜˚˛˝˙ˆ˛ˇ˘ ONE Performance Evaluation of Vertical Roller Mill in Cement Performance Evaluation of Vertical Roller Mill in Cement A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final productCement Grinding Vertical Roller Mills Versus Ball MillVertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industriesvertical roller mill, china roller mill, roller grinding The working principle of HLM Vertical Roller Mill The motor drives the reducer to rotate the millstone, the raw material are send into the center of the millstone from the air lock rotary feeder Under the effect of centrifugal force, the material moves to the edge of the millstone Performance HLM Vertical Roller Mill

Concept Of Vertical Roller Mill Crusher Mills, Cone

vertical roller mill maintenance activities – New service concept improves ATOX mill performance A vertical roller mill has thus been developed and installed, enabling a reduction LUM Vertical Roller Mill XZM Ultrafine Mill Raymond Mill read more There is a variety of things to take into consideration when selecting bentonite clay mill to best suit your needs Energy Efficient And Productive Raymond Mill 1Performance Advantages Raymond mil has the characteristics of simple structure, convenient Vertical Roller Mill, Vertical Roller Mill Operation And MAAG® GEAR MAX Drive for vertical roller mills March 18, 2020 Our MAAG® GEAR MAX Drive is a modular drive system delivering highest power for your vertical roller millMAAG® GEAR MAX Drive for vertical roller millsCombines the performance advantages of the mill and crusher Finished product fineness 03mm CM European Type Coarse Powder Mill Straightthrough centrifugal mill Corollary Equipment Vertical Roller Mill Coal Vertical Roller Mill Slag Vertical Roller Mill MTW European Grinding Mill MW Micro Powder Mill Raymond Mill Hammer Mill Ball MillMTW European Type Trapezium Mill,LM Vertical Roller Mill Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control This automation solution stabilises the VRM to allow operation with lower vibration It also optimises mill performance by making accurate control actions several times per minute and offers continuous monitoring of the milling circuit for improved operationalFOR VERTICAL ROLLER MILLS Loesche

ATOX coal mill

Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the compact ATOX Offering high reliability, with critical process parameters to ensure optimum performance and assurance of lifetime Such activities allow Magotteaux to validate designs and further push the boundaries of wear performance For more information on Magotteaux’s complete line of Vertical Roller Mill Castings and on our overall product lineup andCEMENT AND UTILITIES LABLAORTYESTIRERN˜˚˛˝˙ˆ˛ˇ˘ ONE Performance Evaluation of Vertical Roller Mill in Cement Performance Evaluation of Vertical Roller Mill in Cement A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final productCement Grinding Vertical Roller Mills Versus Ball MillWith regards to comparing grinding mills; what are the advantages of vertical milling machine compared to conventional ball mill? A more appropriate term is vertical roller mill or VRM for shortThere are two different types of vertical mills: Vertical roller mills Such mills normally have intVertimill VS Ball Mill Grinding Classification HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill newhcmilling

How Many Mesh Can CLUM Vertical Roller Mill Grind? Is the

CLUM vertical roller mill is one of the most high output grinding machines on today's market, CLUM vertical roller mill is wide application, outstanding performance in actual production, and it's deeply loved by users How many mesh can CLUM vertical roller mill grind?Is the price expensive? This is a question in the minds of many customers, let's take a lookJul 18, 2016 Optimization of Cement Grinding Operation in Ball Mills Contact Us » Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball millsOptimization of Cement Grinding Operation in Ball Mills LM Vertical Mill With an Output Of 10 Tons Per Hour The LM vertical mill is our more common vertical mill It is an earlier type of mill It has stable performance, low Vertical Roller Mill Manufacturer, Vertical Roller Mill