Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

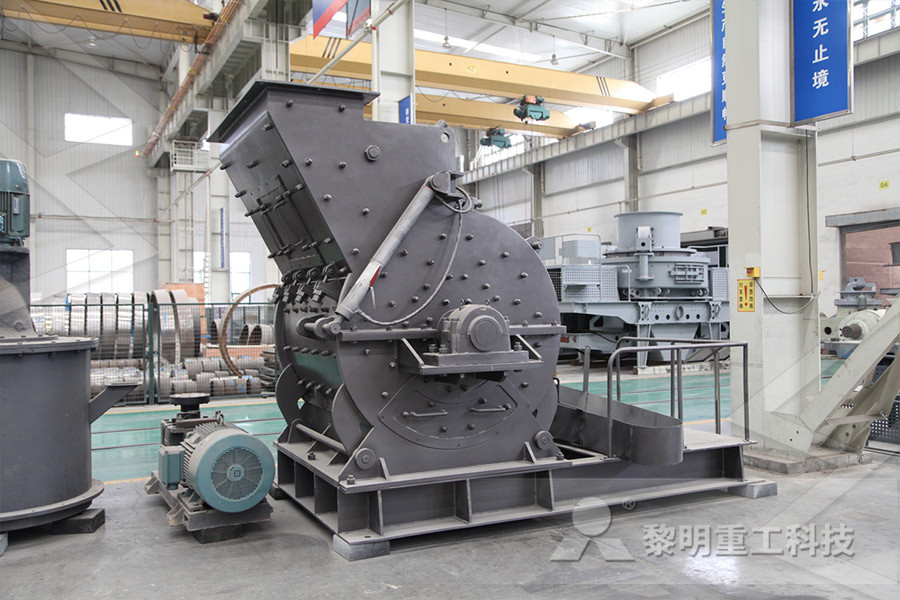

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Flotation Froth an overview ScienceDirect Topics

Processing facilities use both rod millball mill and semiautogenous grinding mill in combination and froth flotation to produce zinc and lead concentrates The concentrator is equipped with process control system and multistream analyzer to facilitate effective QC Metal extraction is Froth Flotation Grinding Mills Froth flotation cells The process of froth flotation entails crushing and grinding the ore to a fine size This fine grinding separates the individual mineral particles from the waste rock and other The figure above is a simplified flow sheet showing the basic steps involved in 1 Froth Flotation Fundamentalgrinding for froth flotation thgroupcozaThe froth flotation process mainly includes grinding, slurry adding, froth flotation separation and dehydration of foam products and tailing products after froth flotation Before the flotation operation, the ore needs to be ground to an optional size range by the grinding mill, generally less than 01 mon Questions About Froth Flotation Process Technologyfroth flotation grinding millsA Review on Novel Techniques for Chalcopyrite Ore Processing121 Flotation Separation Valuable mineral in an ore such as chalcopyrite ore can be separated from each othfroth flotation grinding mills homeideascentrecozaThis complete process plant is for recovering gold by gravity concentration and froth flotation This commonly applies, but is not limited to, ore deposits containing GRG gold and sulphide minerals rich in gold (such as: Pyrite, Copper) This process will also recover silver associated with sulphide mineralsGravity Gold Flotation Plant 911Metallurgist

How to Process LeadZinc Ore by Gravity and Froth Flotation

Dec 16, 2020 Flotation process and equipment of leadzinc ore In the beneficiation of leadzinc ore, flotation is an important process Mixing in mixing tank: After the ground pulp is classified by the classifier, it enters the mixing tank for mixing Control the slurry concentration at 2535%, then add flotation agent to control the slurry pH value 911 and stir it for 615 minFroth Flotation The first successful commercial mill using froth flotation was built in 1905 at Broken Hill, Australia, today recognized as the "home of flotation" Inde pendent experimentation, based on earlier patents, 38 2000 Miniing Histol)' JournalTo Float or Sink: A Brief History of Flotation MillingFroth flotation is an important concentration process This process can be used to separate any two different particles and operated by the surface chemistry of the particles In flotation, bubbles are introduced into a pulp and the bubbles rise through the pulpMineral processing WikipediaGrinding Mineral Processing The ball mill is the fine grinding machine connect the SAG or AG mill and flotation machine Ball mills produce fine particles with a uniform size for flotation, its grinding medias commonly are steel ball The ball mill rolls grinding media together with the ore, as the ore grinds, these balls initially 510 cm in diameter but gradually wear outGrinding And Flotation MillsFroth flotation is a physicochemical separation process Separation is principally based on differences in surface hydrophobicity However, particle size and density have a significant impact Initial flotation patent and application was developed for graphite AMIT 145: Lesson 5 Froth Flotation – Mining Mill Operator

Common Questions About Froth Flotation Process Technology

The froth flotation process mainly includes grinding, slurry adding, froth flotation separation and dehydration of foam products and tailing products after froth flotation Before the flotation operation, the ore needs to be ground to an optional size range by the grinding mill, generally less than 01 mmDec 16, 2020 Flotation process and equipment of leadzinc ore In the beneficiation of leadzinc ore, flotation is an important process Mixing in mixing tank: After the ground pulp is classified by the classifier, it enters the mixing tank for mixing Control the slurry concentration at 2535%, then add flotation agent to control the slurry pH value 911 and stir it for 615 minHow to Process LeadZinc Ore by Gravity and Froth FlotationThis complete process plant is for recovering gold by gravity concentration and froth flotation This commonly applies, but is not limited to, ore deposits containing GRG gold and sulphide minerals rich in gold (such as: Pyrite, Copper) This process will also recover silver associated with sulphide mineralsGravity Gold Flotation Plant 911MetallurgistUsually, the grinding circuit contains at least two interconnected mills with material classifiers (eg cyclones) separating the fine material from the coarse (that then goes for regrinding) The process is energy intensive with power consumption of roughly 20 to 30 MW and feed throughputs of 2,500 to 3,000 t/hr Process variables are mill Advanced Process Control of grinding flotation in Classification of grinding mills Variables in grinding mills Ball Mills, Motion in ball Mills, Critical speed Feeder design Circulating load Rod Mills and its types Understand froth flotation operation for up gradation of ores/minerals, Electrostatic/Magnetic separation operationMML291 Mineral Processing ballalatul Google Sites

R J ATKINSON A M STROUD SAIMM

Some 30% of the copper in flotation tailings of the Carolusberg concentrator at O'okiep Copper Company occurs in the minus 12 micron fraction This is not recoverable by conventional froth floation and is an indication of overgrinding in the mill Flash flotation is Froth flotation is a physicochemical separation process Separation is principally based on differences in surface hydrophobicity However, particle size and density have a significant impact Initial flotation patent and application was developed for graphite AMIT 145: Lesson 5 Froth Flotation – Mining Mill Operator Froth Flotation Introduction June 3, 2012 March 23, 2014 By Steve Blog flotation equipment • flotation machine • froth flotation 0 Comments Flotation is undoubtedly the most important and versatile mineral processing technique, and both its use and application are continually being expanded to treat greater tonnages and to cover new areasFroth Flotation Introduction Henan Deya Machinery Co, LtdUsually, the grinding circuit contains at least two interconnected mills with material classifiers (eg cyclones) separating the fine material from the coarse (that then goes for regrinding) The process is energy intensive with power consumption of roughly 20 to 30 MW and feed throughputs of 2,500 to 3,000 t/hr Process variables are mill Advanced Process Control of grinding flotation in Ore Concentration by Froth Flotation Remember that only 067% of the ore is copper The copper minerals and waste rock are separated at the mill using froth flotation The copper ore slurry from the grinding mills is mixed with milk of lime (simply water and groundup Copper Flotation Elmhurst University

Ball mill grinding site, flotation machine plant YouTube

Jun 20, 2017 Ball mill grinding site, flotation machine plant Baichy mining equipment, crusher, grinder, separator Froth Flotation of Ultramafic Nickel Ore No Pretreatment Duration: 1:11grinding practice in the mills tends to leave the siegenite as binary locked particles in the various product streams (fig 1) Therefore, further grinding to liberate the siegenite particles is required, but is limited by the lower size limita tions of the froth flotation and by grinding energy considerationsContinuous Flotation Testing To Recover Cobalt From Phase 2 will provide a throughput of 72,000 tpa and will involve expansion of the grinding, gravity concentration and froth flotation sections The crushing section will already be capable of the Phase 2 throughput of 72,000 tpa from commissioningCononish Processing Plant : Scotgold Resources LtdMTW Series Grinding Mill adopts a cambered air channel, the tangential air goes into air channel easily because there is little resistance And the inner outlet is very good for the grinded material to spread around and avoid grinding material being jammed Froth Flotation froth flotation process stepsSome 30% of the copper in flotation tailings of the Carolusberg concentrator at O'okiep Copper Company occurs in the minus 12 micron fraction This is not recoverable by conventional froth floation and is an indication of overgrinding in the mill Flash flotation is R J ATKINSON A M STROUD SAIMM

KnowledgeScape Automation Technology

Grinding Smart sensor technology that will automatically determine and maintain the optimal mill load while simultaneously accounting for liner wear and ore body changes in real time Maximize efficiency, avoid liner damage, and increase throughput rates Learn more RecoveryExpert™ Flotation A fully automated level control and reagent Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Milltechonology of grinding ball millfroth flotation of Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; concrete grinding ball mill screener Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Millconcrete grinding ball mill screenerfroth flotation of gangue minerals by froth flotation Oil shale grinding experiments are generally conducted with a conventional ball mill and several hours of grinding are required to produce liberated particles of micron size Such find grinding with a conventional ball mill is energy intensive and requires at least 20 45 kwh/ton energy to grind oilConcentration o! Eastern Oil Shales by Froth FlotationFlotation Froth Flotation Services Grinding Solutions offers a comprehensive range of froth flotation services We specialise in integrating comminution, grinding chemistry and froth flotation to optimise the whole process and/or to better replicate plant conditions Regrinds can be carried out using stirred media mills such as the SMD A Flotation Grinding Solutions Ltd