Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

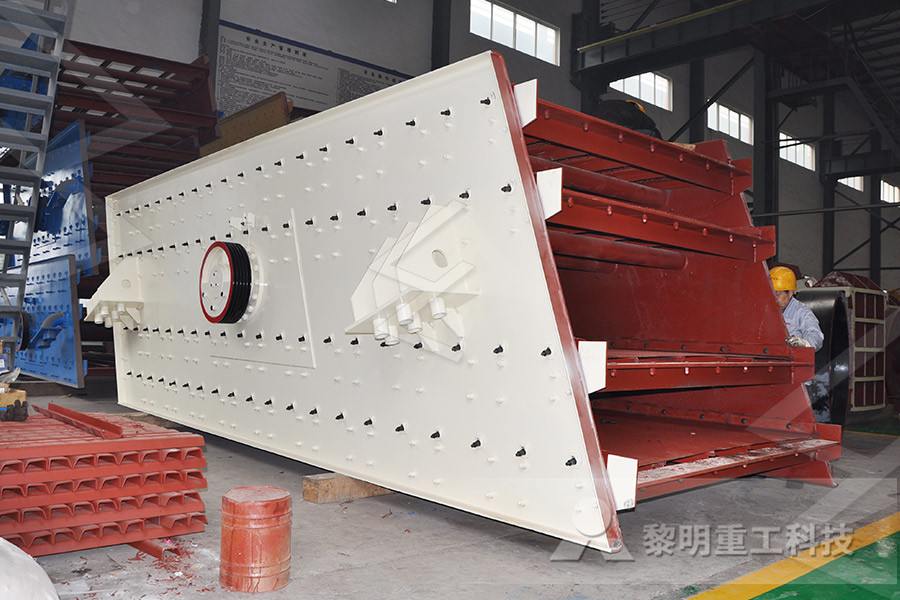

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Coal Hangup in Bowl Mill Operations Bright Hub Engineering

Coal Mill Hangup Bowl mills are used for pulverizing coal in pulverized coal fired boilers The coal to the mill is fed by a coal feeder from the coal bunkerA bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ) The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 USB2 Bowl mill for a coal pulverizer with an air A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body (2) having a central axis; and a bowllike grinding table (3) mounted on a shaft (4) rotatable about said central axis, cooperating with a plurality of grinding rolls (6)The airmill is provided with multiple entry openings (17′, 17″; 18′, 18″; 21, 25) on the Bowl mill for a coal pulverizer with an air mill for We are a world leader in coal pulverizing and overall mill performance with a wide portfolio of services offering covering both horizontal and vertical boiler mills We are committed to key customer issues like improved coal mill and pulverizer performance, reduced maintenance costs, longer periods of operation between outages and product Boiler Mill Coal Pulverizer Service Solutions GE PowerBOWL MILLBowl mills are employed to pulverize the precrushed raw coal to the required fineness before it isadmitted into the boiler furnace for combustion Theoperating characteristics of bowl mills make it thebest mill available for the direct firing systemof the coalCoal Mills in thermal power plant Mill (Grinding

THERMAL POWER PLANTS: COAL HANGUP IN BOWL MILLS

Aug 29, 2010 Coal Hangup in Bowl Mill: Depending on the quality of the coal, sometimes the smooth flow to the coal mill can be disrupted The mill will then trip on flow protection, upsetting boiler parameters and demanding immediate operator corrective action Bowl mills are used for pulversing coal in pulverized coal fired boilers28 rows Wabash Power is the largest supplier of refurbished Raymond bowl mills and hammer Used Hammer Mills and Bowl Mills Wabash Power Equipment Mar 03, 2014 Hot primary air for drying and carrying pulverized coal, enters through insulated Mill side and Liner Assembly Tramp Iron, pyrites and stones coming in the mill with raw coal move out of the bowl and being heavy, fall into the mill side and linear assemblyPrinciple of operation bowl mill SlideShareNomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of rollers three nos X frequency of power supply 50 cyclesIn USA ’x’ means 60 cycles R Raymond, name of the inventorPulverizer Plant OM AspectsAug 22, 2019 Bowl Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Bowl/Coal Mills Klinger Machinery

Raymond® Bowl Mill designed and built for flexibility

The Raymond ® Bowl Mill is considered the finest vertical roller mill available for pulverizing coal Each bowl mill system is designed to achieve the best solution for the processing applicationA bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ) The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 USB2 Bowl mill for a coal pulverizer with an air A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ) The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 USB2 Bowl mill for a coal pulverizer with an air Mill outlet temperature control for bowl mill and tube mill 5141 Objective The outlet temperature of the coal mill is maintained at desired point so that the coal delivered from the mill is completely dry and achieves the desired temperatureCoal Mill an overview ScienceDirect TopicsThe vertical spindle mill crushes coal by feeding it between a grinding roller and either a bowl, table or ring at the bottom Coal enters via the coal feed and falls into the grinding zone, where it is crushed by the grinding wheels The coal particles are spun outwards by the rotation of the grinding table, and transported by the incoming Coalmill optimisation in coalfired power stations aids

Pulverizer Plant OM Aspects

NomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of rollers three nos X frequency of power supply 50 cyclesIn USA ’x’ means 60 cycles R Raymond, name of the inventorRaymond Mill Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill READ MORE Vertical Roller Mill Automatic control system makes remote control, low noise, and integrate sealing device stop dust spill and pollute the environment coal grinding animation in bowl mill coal grinding animation in bowl millAug 22, 2019 Bowl Mills at Klinger Machinery Klinger Machinery Company, Inc PO Box 306, Elizabethville Pa 170230306Bowl/Coal Mills Klinger MachineryA bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 ) The airmill is provided with multiple entry openings ( 17′, 17″; 18′, 18″; 21, 25 USB2 Bowl mill for a coal pulverizer with an air Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW BW's pulverizers, found at Pulverizers / Mills Babcock Wilcox

Bowl mill,coal pulverizer mill,vertical mill,raymond mill

Sep 04, 2018 namaskar dosto is video me hamne bowl mill k baare me bataya hai,ki bowl mill ya coal pulverizer mill kaise work karta hai #bowlmill#verticalmill#coalpulverizermill Share, Support, Subscribe The vertical spindle mill crushes coal by feeding it between a grinding roller and either a bowl, table or ring at the bottom Coal enters via the coal feed and falls into the grinding zone, where it is crushed by the grinding wheels The coal particles are spun outwards by the rotation of the grinding table, and transported by the incoming Coalmill optimisation in coalfired power stations aids USB2 Bowl mill for a coal pulverizer with an air A bowl mill for a coal pulverizer with an air mill for primary entry of air, comprising a substantially closed separator body ( 2 ) having a central axis; and a bowllike grinding table ( 3 ) mounted on a shaft ( 4 ) rotatable about said central axis, cooperating with a plurality of grinding rolls ( 6 )bowl mill coal pulverizer mechanismNomenclatureBowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill If the number is odd then its deep bowl mill 3 number of rollers three nos X frequency of power supply 50 cyclesIn USA ’x’ means 60 cycles R Raymond, name of the inventorPulverizer Plant OM Aspectshow bowl mill coal mill works driesdewildebe Coal pulverizing for coalfired power stations MagotteauxPulverizing coal is essential to make a coalfired station work Magotteaux create Coal pulverizing in power stations ring/bowl depending on mill how bowl mill coal mill works,How Bowl Mill Coal Mi Learn Morehow bowl mill coal mill works

Bowl Mill Spares Roller Shaft Manufacturer from Howrah

Our range of Bowl Mill spares for various Combustion Engineering Designs include mill discharge valve assembly, multiple port outlet, bowl hub, roller journal assembly, upper lower skirts The raw materials used for these components are Nihard, SG iron, steel castings, CI castings alloy steelsJun 09, 2013 Coal from travelling belt of raw coal feeder drops in central feed pipe ( connection between Raw Coal Feeder and Mill) After coal reaches Mill bowl grinding started and hot air also been given to make the pulverised fuel dried enough to classifier chamber The portion of the coal which cannot be grinded finds its way to mill rejectABC OF THERMAL POWER PLANT: MILLS IN A THERMAL POWER Mills are capable of grinding down to 90% minus 200 mesh as well as grinding a 40 hardgrove coal but at a lower rating 593 Raymond Bowl Mill Wabash Power Equipment Company 593 Bowl Mill 2 (Two) Reconditioned Center Feed #593 CE Raymond Bowl Mill Coal Pulverizers rated at a base capacity of 28,200#/hr on 55 grindibility coal pulverized to 70 raymond coal bowl mill side feederRaymond Bowl Mill Coal From Wabash Power Refurbished 533 bowl mill raymond wabash power equipment 4 four reconditioned 533 ce raymond bowl mill coal pulverizers rated at a base capacity of 20 000hr on 55 grindibility coal pulverized to 70 minus 200 mesh mills are capable of grinding down to 90 minus 200 mesh as well as grinding a 40 hardgrove coal but at a lower ratingRaymond Bowl Mill Coal PulverizersBowl mill,coal pulverizer mill,vertical mill,raymond mill Sep 04, 2018 namaskar dosto is video me hamne bowl mill k baare me bataya hai,ki bowl mill ya coal pulverizer mill kaise work karta hai #bowlmill#verticalmill#coalpulverizermill Share, Support, Subscribe Author: Knowledge Boosting; Improving Coal Pulverizer bowl mill coal bowl mill coal pulverizer idconecrusher ME Mining Machinery

RollBowl COP A full featured mill monitoring solution

RollBowl COP is a patented technique that is used to monitor and improve the performance of coal pulverizers RBC provides nonintrusive, dynamic analysis of the grinding elements, bearings and gearbox Proper Mill Adjustment