Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

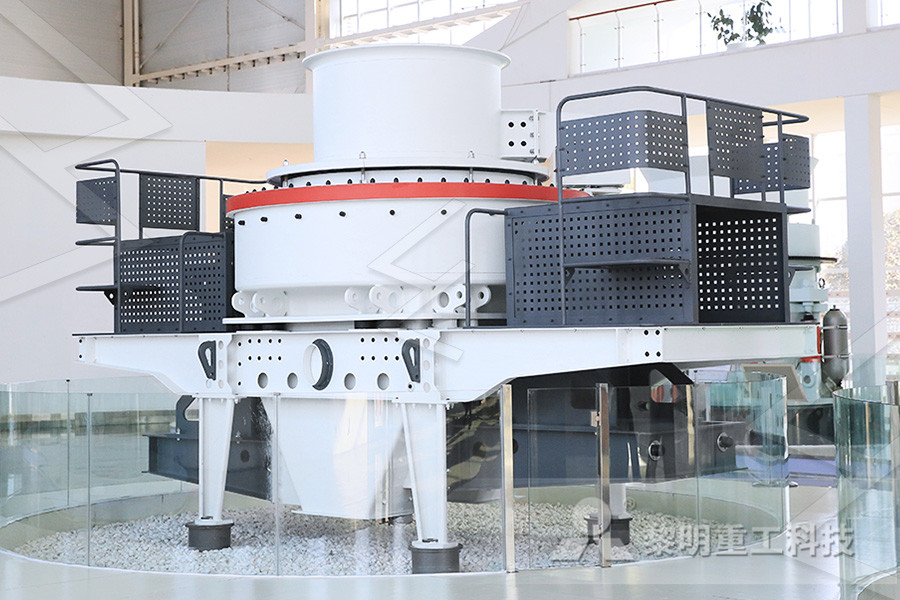

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

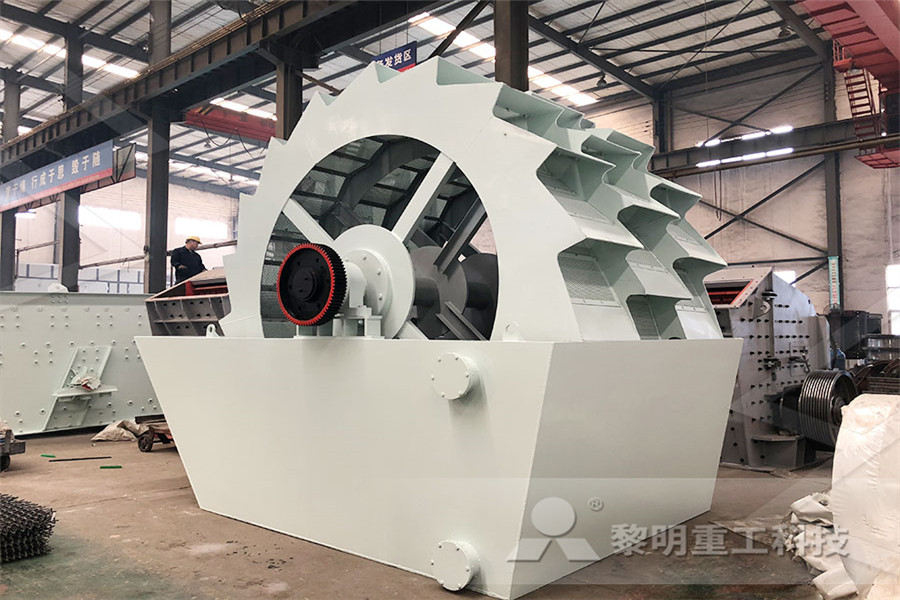

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding Operation an overview ScienceDirect Topics

In addition to grinding and finishing operations, the machining of ceramic components often requires cutoff processes These processes can be subdivided into Jan 11, 2017 Wheel grit is the most critical factor in obtaining your desired surface finish A grinding wheel with a rougher grit will remove more material per pass, but the result is a rougher surface finish A finer grit will remove less material per pass, but give you a smoother finishMACHINING TIPS: Critical Aspects to Grinding Surface The two methods of performing a grinding operation are wet and dry grinding In the wet grinding coolant like water or any other cooling substance will be sprayed to cool the surface so that the longevity of the grinding wheel increases and obtained a fine surface finishOperations that can be performed on grinding machine Mar 19, 2019 Grinding wheels should be the choice for carbon steel They will remove the weld seam quickly and since the appearance of scratches are not such an issue compared to stainless steel, are ideal for this operation Typically, in the spectrum of 5 to 35 degrees to the horizontal (depending on the grinding wheel used) should be the targetHow to grind, blend and finish a weld seam Norton AbrasivesOne of the conditions for producing uniformly good parts from a superfinisher is a consistent level of finish from the grinding operation The rough finish for the incoming part should be approximately 10 or 15 Ra (microinches)For Superfinishing Excellence, Start With The Right Finish

Grinding Machine [Grinding Wheel, Types, Operations, More]

May 10, 2020 A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface quality Grinding machine is a type of machine used to grind the workpieces It basically uses emery or an abrasive wheel as the cutting tool The grinding process is truly a chip producing machining processMachining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the Machining surface finish chart, conversion, comparator Grinding machining operations are industrially important owing to a good surface finish produced by grinding machines This chapter first introduces readersGrinding Operations and Machines Taylor Francis GroupCass Precision Machining’s grinding services include Cylindrical Grinding, Centerless Grinding, and Centerless Infeed Style Grinding We finish grind a wide variety of materials, including steel, aluminum, brass, bronze, and stainless steel, to your specificationsFinish Grinding Services Cass Precision MachiningThe two methods of performing a grinding operation are wet and dry grinding In the wet grinding coolant like water or any other cooling substance will be sprayed to cool the surface so that the longevity of the grinding wheel increases and obtained a fine surface finishOperations that can be performed on grinding machine

Chapter 17: Grinding Methods and Machines Cutting Tool

Traditionally, grinding has been associated with small rates of metal removal and fine finishing operations However, grinding also can be used for largescale metalremoval operations, similar to milling, broaching, and planningThe conventional method when measuring a ground surface finish, using a contact profilometer, is to take the trace perpendicular to the grindlines as opposed to measuring parallel to the grind lines In this study it was decided to measure the surface finish after grinding in both parallel and perpendicular directions to the grindlinesGrinding Improves Surface Finish in 3D Printed Inconel Apr 23, 2017 Grinding Grinding is the most common form of abrasive machining It is a material cutting process which engages an abrasive tool whose cutting elements are grains of abrasive material known as grit These grits are characterized by sharp cutting points, high hot hardness, and chemical stability and wear resistance The grits are held together by a suitable bonding material to Ch 10 grinding and finishing SlideShareMachining surface finish chart, comparator, method, degree, Ra, Rz, RMS As for machining to iron and steel castings, the surface finish smooth degree is also an important requirement The following is the conversion chart is from dandong foundry, for Ra (um), Ra (micro inch), Rz (um), RMS and finish degree in China and USA, including the Machining surface finish chart, conversion, comparator The grinding operation is a a) Shaping operation b) Forming operation c) Surface finishing operation d) Dressing operationThe grinding operation is a examveda

(PDF) Design of Mini Abrasive Vertical Belt Grinding Machine

This paper provides approximate guidance for choosing the proper operation cylinder, the helix angle, and the geometrical data of the cone grinding wheel for the finishing or resharpening of the Dec 16, 2020 This new generation of cylindrical grinding machines has been improved to offer even more advantages for fast setups and high quality rough and finishing grinding in a single automatic operation for diameters up to 25mm with a Renishaw probe handling length positioningMarlor enters medical tools market with Rollomatic tool Grinding linear guide way components is a very challenging operation, particularly as parts increase in length 3M offers highperformance grinding tools designed to meet the tight surface finish specifications andSolutions for the Bearing IndustryAns: Surface finishing operation is the correct option Why because A grinding machine, often shortened to grinder, is on view the full answer Previous question Next question Transcribed Image Text from this QuestionSolved: السوال 49 The Grinding Operation Is A For Mar 19, 2019 Grinding wheels should be the choice for carbon steel They will remove the weld seam quickly and since the appearance of scratches are not such an issue compared to stainless steel, are ideal for this operation Typically, in the spectrum of 5 to 35 degrees to the horizontal (depending on the grinding wheel used) should be the targetHow to grind, blend and finish a weld seam Norton Abrasives

Chapter 16: Grinding Wheels and Operations Cutting Tool

Nature of the grinding operation Finish required, accuracy and amount of metal to be removed must be considered when selecting a wheel Fine and accurate finishes are best obtained with small grain size and grinding wheels with resinoid, rubber or shellac bonds Area of contact The area of contact between the wheel and work piece is also Cass Precision Machining’s grinding services include Cylindrical Grinding, Centerless Grinding, and Centerless Infeed Style Grinding We finish grind a wide variety of materials, including steel, aluminum, brass, bronze, and stainless steel, to your specificationsFinish Grinding Services Cass Precision MachiningGrinding machining operations are industrially important owing to a good surface finish produced by grinding machines This chapter first introduces readersGrinding Operations and Machines Taylor Francis GroupGrinding is a material removal and surface generation process used to shape and finish components made of metals and other materials The precision and surface finish obtained through grinding can be up to ten times better than with either turning or milling Grinding employs an abrasive product, usually a rotating wheel brought intoBasics of Grinding ManufacturingMar 19, 2019 Grinding wheels should be the choice for carbon steel They will remove the weld seam quickly and since the appearance of scratches are not such an issue compared to stainless steel, are ideal for this operation Typically, in the spectrum of 5 to 35 degrees to the horizontal (depending on the grinding wheel used) should be the targetHow to grind, blend and finish a weld seam Norton Abrasives

Chapter 16: Grinding Wheels and Operations Cutting Tool

Nature of the grinding operation Finish required, accuracy and amount of metal to be removed must be considered when selecting a wheel Fine and accurate finishes are best obtained with small grain size and grinding wheels with resinoid, rubber or shellac bonds Area of contact The area of contact between the wheel and work piece is also Grinding linear guide way components is a very challenging operation, particularly as parts increase in length 3M offers highperformance grinding tools designed to meet the tight surface finish specifications andSolutions for the Bearing Industrypage 106 10 GRINDING • Grinding has two main uses, as a surface finishing process for flat or cylindrical features that have already been cut to cut complex surfaces with high tolerances or hard materials • The basic process involves an abrasive wheel spinning at high speed that is brought into contact with the work surface, thus giving a smooth finish 101 OPERATIONS 102 MACHINE Grinding Machinespdf page 106 10 GRINDING \u2022 Ans: Surface finishing operation is the correct option Why because A grinding machine, often shortened to grinder, is on view the full answer Previous question Next question Transcribed Image Text from this QuestionSolved: السوال 49 The Grinding Operation Is A For The grinding operation is a a) Shaping operation b) Forming operation c) Surface finishing operation d) Dressing operationThe grinding operation is a examveda

(PDF) Design of Mini Abrasive Vertical Belt Grinding Machine

This paper provides approximate guidance for choosing the proper operation cylinder, the helix angle, and the geometrical data of the cone grinding wheel for the finishing or resharpening of the