Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

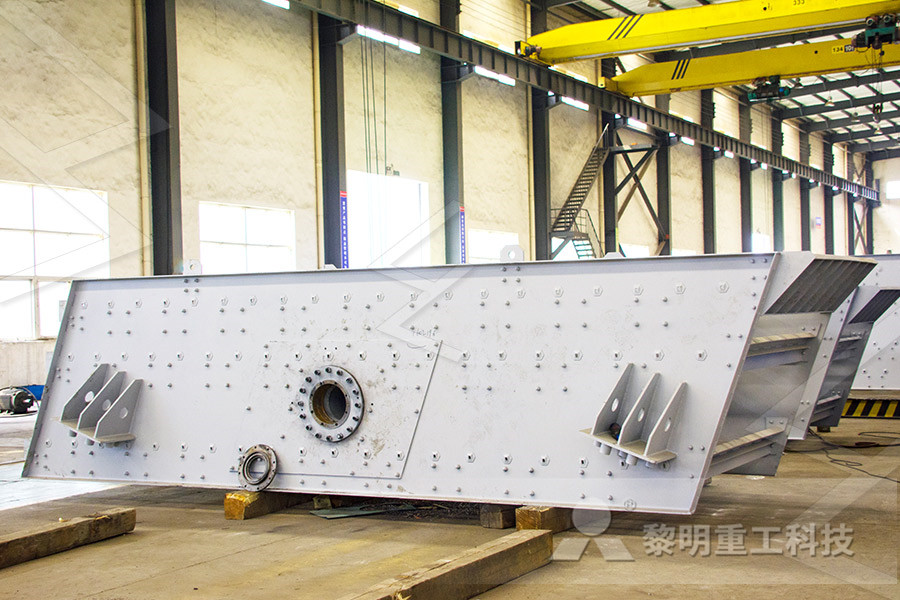

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Vibrating Screen Types Blog mekaglobal

Vibrating Screen Types Screen Types Inclined Screen Inclined screens are the most basic type of screen, fixed to an inclined frame at an angle of between 15° and 30° The entire body of the screen vibrates on helical springs circularly with the same Inclined screen Vibrating inclined screen is the most popular types of vibrating screens The screen fix to the tilted frame at an angle of 15 to 30 degrees The inclined screen is usually designed in a multilayer structure and can be classified into 25 grades And the screen Types Of Vibrating Screens Introduction And DifferenceApr 27, 2020 Professional vibrating screens makers could give serious vibrating screen value, assorted variety redid vibrating screen models, auspicious afterdeals administration, save parts, and can keep on offering types of assistance for clients’ Top 10 Vibrating Screens of 2020 Screening Materials Vibrating screen is a mechanical equipment that uses vibrating screen panels to classify the mixture which contain different particles according to particle size According to different structure and use, vibrating screens usually be devided into many types by the vibrating screen manufacturersVibrating Screen Types Working Principle [How To Choose The quarry vibrating screen is mainly used to screen gravel, and the quality of the screen mesh determines the material screening efficiency Therefore, quarry investors or equipment purchasers will ask the manufacturer for information about vibrating screen media types when choosing a vibrating screenWhat Is Vibrating Screen MeshTypes, Specifications And

Vibrating Screens (Screen Mesh) Atlas Industries

Vibrating Screens High Quality Screening Woven wire vibrating screen mesh is the most common type of screening media The diversity of applications and low cost has made it a very popular choice on the market A lot of construction industries use steel wire screen meshOct 16, 2015 The two most common types of vibrating screen are the inclined and the horizontal In the inclined screen, the single unbalance, rotating on a horizontal axis, generates a circular motion in the vertical plane Since this motion has no positive transport property, the screen surface is sloped at 15 degrees to 20 degrees to cause the particle Screening of Materials and Types of Screens – IspatGuruThe Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45° Each has a 063” dia wire screen with 1/8” clear opening, moving under a particle travelling at an assumed 20 fpm, for A, 40 fpm for B, 80 fpm for C, and 60 fpm for D Omitting detailsScreening Theory and Practice Triple/S DynamicsMechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling A method of separating solid particles according to size alone is called screeningMechanical screening WikipediaApr 27, 2020 A circular vibrating screen is another sort of vibrating screen with a multilayer screen and high proficiency As per the kind of materials and the prerequisites of clients, you can use its multiple screening plates The circular vibrating screen is Top 10 Vibrating Screens of 2020 Screening Materials

Vibrating Screens Manufacturer in India, Different Type of

Sep 24, 2019 Inclined Vibrating Screens are one of the most common types of Vibrating Screens that are fixed to the inclined frame at the precise angle of 15 degrees or 30 degrees When it is operated the body of the screen vibrates and uses the helical spring circularly and as a result, the material flow is delivered by the gravitational speedWhat are vibrating screens and which are its main applications for use Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening The screens serve to classify the different particles by size, starting from a bulk product in a continuous processBasic concepts of vibrating screens: What they are, what Mar 01, 2018 Circular screens: These type of screens are also called circularmotion vibrating screens They are commonly used to classify medium to coarsegrained bulk materials (50 mm to Screening Plants — Types, Working Principle Applications Dec 21, 2020 The MarketWatch News Department was not involved in the creation of this content Dec 21, 2020 (Market Insight Reports) Selbyville, Delaware Global Vibrating Screen Vibrating Screen Market Size Outlook 2025: Top Companies Vibratory Screens Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens make the specificationVibratory Screens McLanahan

Vibratory Screens McLanahan

Vibratory Screens Screening is an important part of processing and is used to separate material according to its size Material is typically fed to a single, double or tripledeck screen to make the required sizes Screens can be considered the cashbox of the operation, because while crushers make the gradation, screens Vibrating Screens High Quality Screening Woven wire vibrating screen mesh is the most common type of screening media The diversity of applications and low cost has made it a very popular choice on the market A lot of construction industries use steel wire screen meshVibrating Screens (Screen Mesh) Atlas IndustriesThe vibrating Inclined Screen is the most popular type of screen There are various types of Inclined Screens, including two and four bearing, highspeed, and highfrequency screens The overwhelming majority of installations today are either two or three decks, though there are single and four deck varieties available as wellInclined Screens McLanahanMay 06, 2019 Circular vibrating screens and linear vibrating screens are common screening equipment in industrial production However, their working principle is different from that of suitable materials When selecting vibrating screens, according to the type of materials to be screened, The particle size is chosen to suit the vibrating screenLinear or circular vibrating screen, what is the While a large number of engineers try to minimise the vibrations in different applications, vibrating screen manufacturers try to make the best of it Proper vibrating patterns are not possible without flexible mounts Springs are the most common type of vibrating screen suspension They are durable and easy to install and serviceVibrating Screen Accessories YUDIN Equipment

What is a Vibrating Screen? wiseGEEK

Dec 15, 2020 Most vibrating screens have four or more levels of screens stacked on top of one another The screens are made of wire mesh and come in a variety of sizes in order to accommodate different jobs The vibrating screen operates by having the items that are to be separated, such as marbles of different sizes, placed on the screen on the top layerTechnical data vibrating sieve Manufacturer ZEWE GmbH Type vibrating screen SWS 15/35 Year of manufacture 08/2019 Operating hours approx only 10 hours Dimensions vibrating screen 3,500 x 1,500 mm Perforation vibrating screen 60 x 60, 150 x 60 and 325 x 60 mm Dimensions of the exchangeable steel screen plates 1,480 x 560 mm (w x l) Power vibration motors 2 x 4 kW, 400 V, 50 Hz Condition: vibrating screen used machine for sale9 Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens Screening and Types of Screens Information on screening and types of screens is given in this chapter Size Control Size control is the process of separating bulk material into two or more products on basis of their sizeConstruction, Working and Maintenance of Electric the most abrasive material types And, Deister screens are backed by a followthrough parts and service policy without equal – for Deister top management is personally interested in the continued profitable operation of every Deister screen Deister Vibrating Screens have many outstanding features which are standard on each unit:HEAVY DUTY INCLINED VIBRATING SCREENSPolyurethane dewatering screen board pu disintegrate for dewatering screen deck is a kind of screens made of steel edge and polyurethane surface This structure guarantee the high rigidity and much better wear opposition than the woven vibrating screen work and punctured vibrating screen workPolyurethane Screens China Polyurethane Screens suppliers

Vibramech

Vibramech Footprint Vibramech has an installed base of over 8 000 pieces of mineral processing equipment worldwide We have supplied vibrating mineral processing machines extensively throughout Africa and have equipment installed in, amongst other regions, Russia, Kazakhstan, China, Canada, USA, South America, Australia, India, United Kingdom and the PhilippinesFeb 22, 2019 9 differences between linear and circular vibrating screen Posted: Vibrating screens have a wide variety of types according to the movement track of materials, such as, circular vibrating screens, linear vibrating screens and fine screening machine, and these three are the most commonly used types in daily production9 differences between linear and circular vibrating screenApr 01, 2019 Application of different kinds of vibrating screens in coal cleaning production (without subsystem of slime water treatment) The main structures of a vibrating screen are as shown in Fig 2 (a) It usually consists of a screen body, a screen surface, four groups of vibration isolation system, and an excitation system (ie, a unilateral A review on the advanced design techniques and methods of types of vibrating screens at brick manufactiring plants Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry types of vibrating screens at brick manufactiring plants