Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

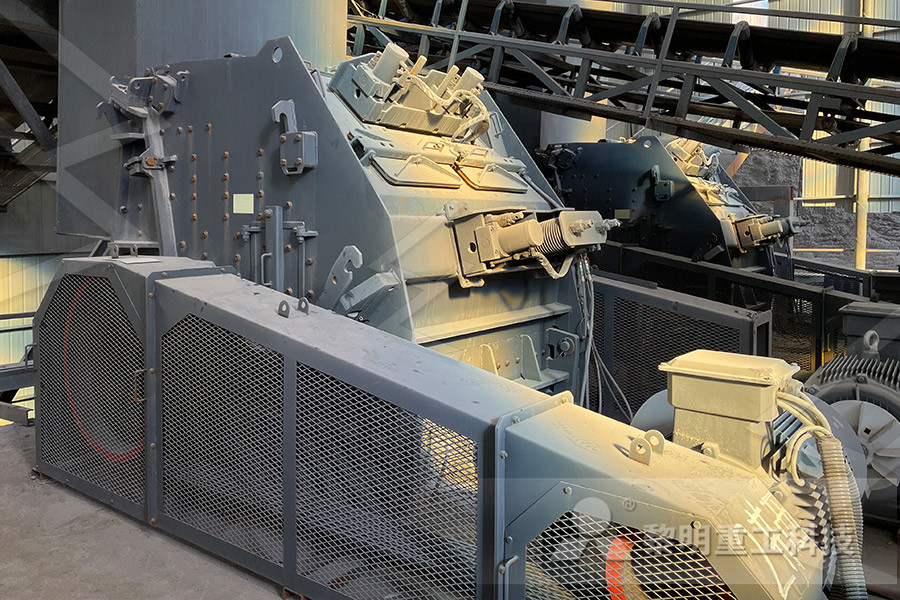

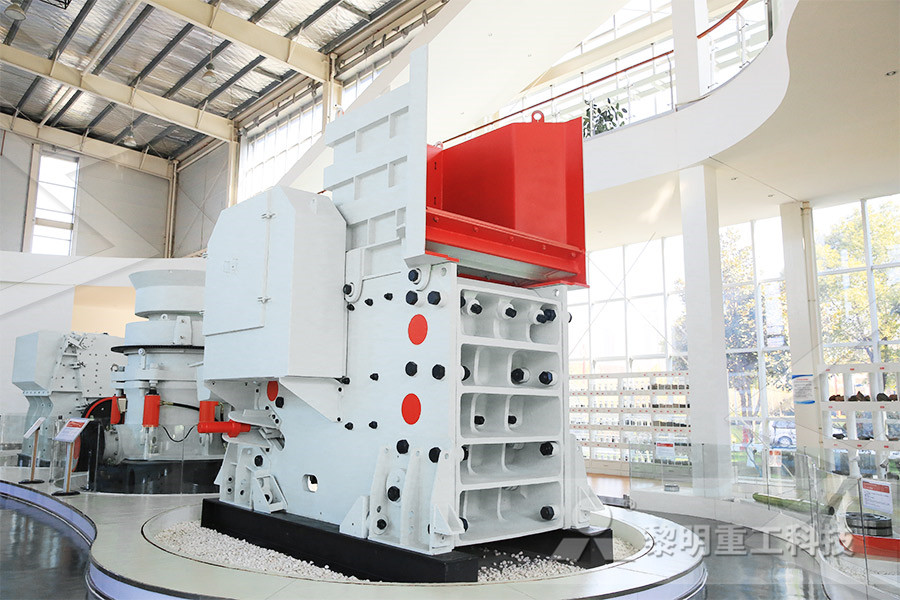

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What is Single Double Side Fine Grinding?

Fine Grinding (flat parts – single or doubleside) is the abrasive machining process for removing material using a bonded Superabrasive wheel at low speed with a liquid to keep the part cool The fixed grain of a geometrically indefinable cutting shape acts like a plow (fig 3) and material is removed by microgrooving /cutting (fig 4)Fine grinding produces a surface with little deformation that can easily be removed during polishing Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, 90 and 60 µmMetallographic grinding and polishing insight StruersAug 01, 2009 With fine grinding, air classifiers can be integrated into mills that allow only those particles with the desired endparticle size to pass through the classifying wheel, but which return coarser particles for Fine Grinding With Impact Mills Chemical Engineering Dec 23, 2018 The grinding machine provides high accuracy and fine surface finish with minimum tolerances The machining process is done by the abrasive action of the grinding wheel; the abrasives are embedded over the periphery of the rotating wheel In Grinding machine grinding wheel is work as a cutting tool and responsible for all machining processesGrinding Machining Process : Complete Notes mech4studyGrinding is a subset of cutting, as grinding is a true metalcutting process Each grain of abrasive functions as a microscopic singlepoint cutting edge (although of high negative rake angle), and shears a tiny chip that is analogous to what would conventionally be called a Grinding (abrasive cutting) Wikipedia

Continuous Micronizing Fine Grinding Equipment and

MICRONIZING FINE GRINDING Micronizing serves a pivotal role in particle processing systems, aiming to break materials down into fine powders either as Fine grinding produces a surface with little deformation that can easily be removed during polishing Because of the drawbacks with grinding papers, alternative fine grinding composite surfaces are available, in order to improve and facilitate fine grinding, A high material removal rate is obtained by using grain sizes of 15, 90 and 60 µmMetallographic grinding and polishing insight StruersA finegrinding model can be constructed using a chart in the form of specific energy versus P80 size, as in Figure 3, and the regression functions your preferred spreadsheet At least two points are needed to construct such a chart, and if two surveys are not available then a usable model is still possible byFine Grinding A RefresherDec 23, 2018 The grinding machine used for finishing only after the machining done by some other machine tools We can say that the function of the grinding machine comes into play after the machining of a work piece by turning or milling machines The grinding machine provides high accuracy and fine surface finish with minimum tolerancesGrinding Machining Process : Complete Notes mech4studyFine grinding serves no practical purpose! In spite of advice you’ll hear from most other cannabis cooks, and in spite of it being a builtin function of a popular "magical" cannabis butter making gadget, I always advise people to NOT finely grind cannabis before making butter, oil, or other infusions for a To Grind or Not to Grind: How to Prepare Marijuana for Cooking

Grinding of maize: The effects of fine grinding on

Mar 01, 2016 The particle size of maize flour has a significant effect on its functional and physicochemical properties In this study, maize grits were ground for various time intervals (35, 4, 5, 6, 10 and 14 min), and grinding effects on compositional, functional and physicochemical properties of maize flour were evaluated by using rapid visco analyzer (RVA), differential scanning calorimeter Our SMF fine granulators and PU impact disc pulverizers have been developed for use in the fine grinding of plastic granulates and waste, and other soft to mediumhard materials The final particle sizes to be achieved lie in the range of 01000 mm to 0200 mm, Fine grinding by granulators and pulverizers Herbold Apr 28, 2020 The metal grinder functions similarly to a cheese grater – just rub the bud over the shredding surface We recommend arranging the metal grinder card over a Pebble and rubbing the bud back and forth for a perfect grind with no mess Grinder cards are manufactured with different grinding surfaces from fine to coarse for a range of uses5 Reasons To Grind Your Cannabis (and How To Do It Even the grinding wheel are different type as discussed above and there uses for the different workpiece Grinding wheel bond types: A bond is an abrasive material used to held abrasive particles together The bonding material does not cut during the grinding operations Its main function is to hold the grains together with varying degrees of Grinding Wheel: A Definite Guide For You (With PDF)A Dremel bit is a tool bit that can change the function of the Dremel rotary tool and allow it to do a variety of different jobs The thin grinding wheels can be used for partingoff and cutting while the thicker wheels are good for general purpose to 600 grit (fine) The standard 150 grit diamondtipped bit can work very as an all Dremel Bits Guide: List of Best Dremel Bits and Their Uses

What grit sequence do you use for fine grinding? ATM

Sep 09, 2013 What grit sequence do you use for fine grinding? posted in ATM, Optics and DIY Forum: A few centuries ago when I was young I used WillmannBells 120, 220, 320, 500 grit SiC, then 12 and 5 micron aluminum oxide Seems an awful lot of sizes compared to what others have recommended Mel Bartels uses just 120, 220, 500 SiC and 9 micron Al2O3Fine grinding lessens this effect, and early cements had to be stored for several months to give the calcium oxide time to hydrate before it was fit for sale From 1885 onward, the development of specialized steel led to the development of new forms of grinding equipment, and from this point onward, the typical fineness of cement began a steady Cement mill WikipediaKeep in mind that a grinding wheel is a form of cutting tool, and except in the case of wheel for general purpose grinding, the abrasive, grit size, grade and structure, bond type should be selected to fit the particular job on which the wheel is to be used, just as a cutter, drill or tap is selected for its specific jobChapter 5: Surface Grinder – Manufacturing Processes 45(Exercise of Functions) (Fine Grinding Ltd) Direction 2019 The Secretary of State gives the following direction in exercise of the powers conferred by regulation 33(1)(b) of the Environmental Permitting (England and Wales) Regulations 2016(a) Citation and commencement 1THE ENVIRONMENTAL PERMITTING (ENGLAND AND Precision Surface Grinding Machine PSG/ACCSA1 Series OKAMOTO MACHINE TOOL WORKS, LTD 2993 Gobara, Annaka, Gunma, Japan 3790135 TEL : +81273889595 FAX : +81273851144 URL : okamotocojp When and before using our products, you are requested to well go through the articles on danger, warning and attention for the sake of safety described in operation manual Precision Surface Grinding Machine PSG/ACCSA1

Fine Grinding A Refresher

A finegrinding model can be constructed using a chart in the form of specific energy versus P80 size, as in Figure 3, and the regression functions your preferred spreadsheet At least two points are needed to construct such a chart, and if two surveys are not available then a usable model is still possible byFine grinding serves no practical purpose! In spite of advice you’ll hear from most other cannabis cooks, and in spite of it being a builtin function of a popular "magical" cannabis butter making gadget, I always advise people to NOT finely grind cannabis before making butter, oil, or other infusions for a To Grind or Not to Grind: How to Prepare Marijuana for Cooking11 Grinding Media Types To date, all IsaMill installations have taken advantage of the technology’s ability to use a low cost, but relatively low quality grinding media such as silica sand, river pebble, smelter slag or fine primary mill scats (autogenous milling) Whilst the Improving The Efficiency Of Fine Grinding – Developments Keep in mind that a grinding wheel is a form of cutting tool, and except in the case of wheel for general purpose grinding, the abrasive, grit size, grade and structure, bond type should be selected to fit the particular job on which the wheel is to be used, just as a cutter, drill or tap is selected for its specific jobChapter 5: Surface Grinder – Manufacturing Processes 45grinding wheel and one fine grinding wheel are usually mounted on the machine for convenience of operation Each It performs internal and external cylindrical grinding among its other functions Refer to Chapter 9 for a description of this machine SURFACE GRINDING MACHINE The surface grinding machine is used for grinding flatGRINDING MACHINES

5 Reasons To Grind Your Cannabis (and How To Do It

Apr 28, 2020 The metal grinder functions similarly to a cheese grater – just rub the bud over the shredding surface We recommend arranging the metal grinder card over a Pebble and rubbing the bud back and forth for a perfect grind with no mess Grinder cards are manufactured with different grinding surfaces from fine to coarse for a range of usesApr 23, 2017 IES 1999 Consider the following reasons: 1 Grinding wheel is soft 2 RPM of grinding wheel is too low 3 Cut is very fine 4 An improper cutting fluid is used A grinding wheel may become loaded due to reasons stated at (a) 1 and 4 (b) 1 and 3 (c) 2 and 4 (d) 2 and 3 98Ch 10 grinding and finishing SlideShareImpact mills will allow you to adjust the fineness levels, for example when you are fine grinding different spices Air classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutions And when you are trying to reduce the particle size of Food Milling Machines Equipment Ask the industry experts!To reduce to small bits or crush to a fine powder: grind wheat into flour; grind coffee beans b Grinds definition of grinds by The Free Dictionary form, forge, work make something, usually for a specific function; "She molded the rice balls carefully"; "Form cylinders from the dough"; "shape a figure"; "Work the metal into a sword Grinds definition of grinds by The Free DictionarySep 11, 2019 Utrafine grinding mill usually means the grinding mill can grind the material to ultra fine powder In mining industry, there are many types of ultra fine grinding mill like Raymond mill ,HGM micro powder grinding mill,Ball mill, Jet mill,CLUM ultWhat is an ultrafine grinding mill? Quora

Sboly Coffee Maker A 2 in 1 Grind And Brew Is More

You don’t have to guesstimate when to stop the grinding function The fine grinding option powers the grinder 10 seconds more than the coarse grind Fine grinding coffee beans is perfect for strong coffee lovers, while the coarse grinding setting is a good option for lightly flavored coffee After grinding, the machine begins to brew your cup Grinding in ball mills is an important technological process applied to reduce the feed and only the fine product is obtained at the output of the grinding circuit In These operations are characterized by two functions: the selection function Si,Grinding in Ball Mills: Modeling and Process ControlFine grinding in stirred bead mills is becoming increasingly common in the mineral processing Where A is a complex function that they don’t define, dk is the stirrer diameter, Dm the mill diameter, dg the grinding bead diameter, n the stirrer speed, the slurry density However, despite apparentlyA Power Model For Fine Grinding HIGmillsJan 01, 2020 As the grinding proceeded (≥3 min), the relative mass distributions of the ground products for wet grinding was best represented by the GGS distribution function However, the GM distribution function provided the best fitting performance when it was applied to the experimental data for dry grindingWet and dry grinding of coal in a laboratoryscale ball