Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

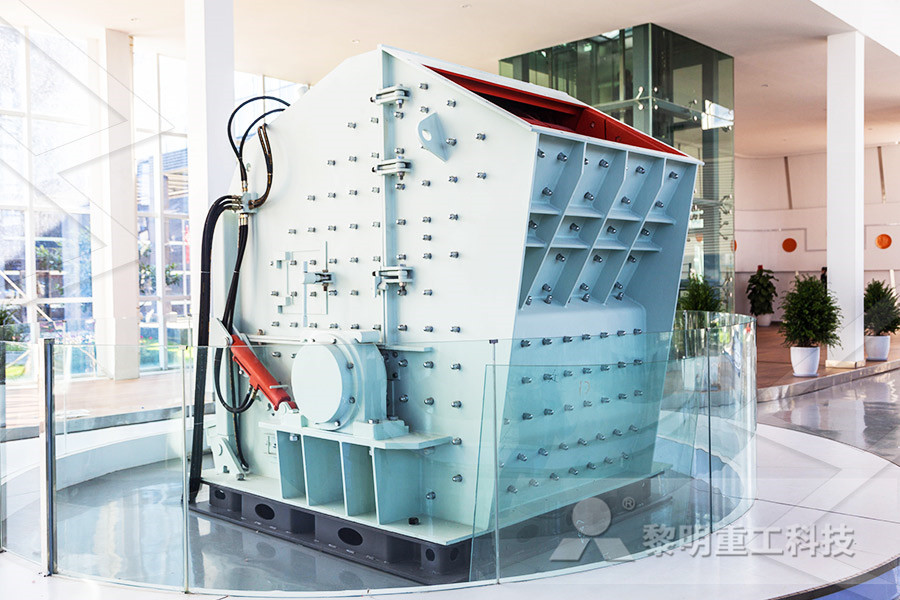

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

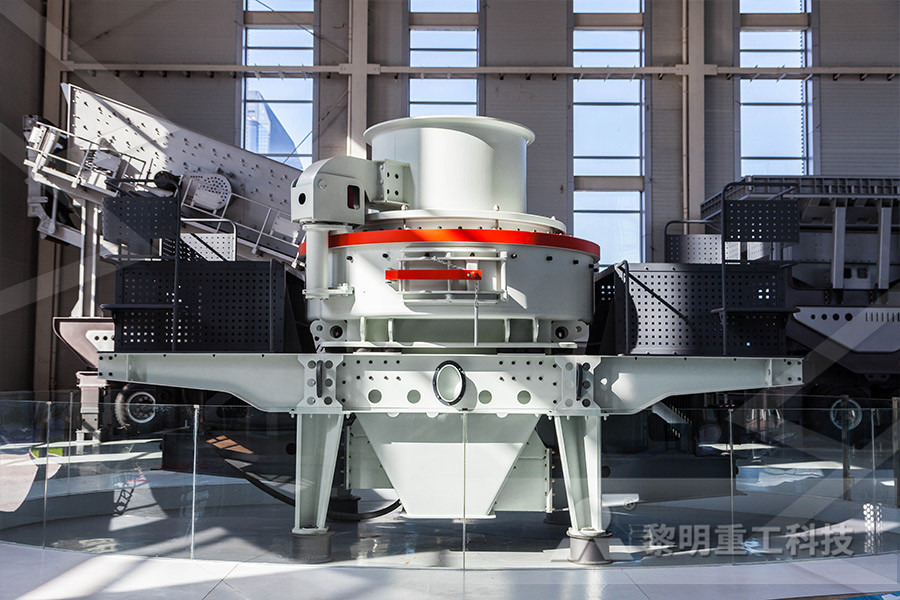

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Can coal washing be done more sustainably?

Sep 14, 2020 Coal washing, or coal beneficiation, is widely seen as an efficient method for getting the most from runofmine coal On the other hand, it is a waterintensive process: typically, washing one tonDec 29, 2019 Coal washing, or coal beneficiation, is widely seen as an efficient method for getting the most from runofmine coal On the other hand, it is a waterintensive process: typically, washing one ton of coal consumes about 45 m 3 liters of waterCan coal washing be done more sustainably? OutotecCoal washing and beneficiation for South African producer Coal washing and beneficiation One of the simplest and bestknown techniques for reducing emissions is the washing of coal In many ways, South Africa leads the way in such technology as the coals mined in the country are poorer quality and require cleaning to be exportedcoal washing and coal benificiationJul 18, 2018 In coal Beneficiation, artificial suspension of above mentioned densities are produced and coals are subjected to float and sink The coals which float at 15 specific gravity are called clean coal and the sinks are put to another suspension of specific gravity of 17COKING COAL BENEFICIATION SciTech Connectprocess of Coal Washing Considering the fact of requirement of millions of tones clean coal for the endusers, mainly power houses, this problem will have to be solved effectively The benefits of low ash coal burning in boilers are realized but reimbursement of extra cost of beneficiation for washed noncoking coal needs to be consideredCoal Beneficiation Technology for Coking NonCoking Coal

Coal Beneficiation Technology 2007 Initiatives, Policies

EITHER the Coal producer sells beneficiated coal OR Consumers set up coal beneficiation units at the mine site Or a third party undertakes coal washing on Build Own Operate basis or on contract at the initiative by the producer or the consumerBeneficiation can be continued at the postmining stage through separation of stones, crushing and screening, followed by coal washing Coal Beneficiation is a process where coal is subjected to a medium of defined specific gravity Heavier material sinks (rejects) and lighter coal floats (clean coal)Coal beneficiation: Policy priorities for India ORFAir supplied through air holes in the beneficiation bed which agitates the raw coal resulting in stratification of coal as per its relative densities lighter coal forms the upper layer and heavier coal forms the lower layer Upper good coal goes to conveying trough and higher density coal moves to waste sideCOAL BENEFICIATION IIMCoal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer)Coal Washing Plant,Coal Washery,Coal WashingBeijing HOT Sep 14, 2020 Coal washing, or coal beneficiation, is widely seen as an efficient method for getting the most from runofmine coal On the other hand, it is a waterintensive process: typically, washing one Can coal washing be done more sustainably?

Coal Washing, Kentucky Geological Survey, University of

Oct 07, 2019 Coal suppliers try to find coals that most closely match those requirements Coal is treated in processes called beneficiation to prepare a material that meets the customer's needs and is as homogenous as possible Samples of coal from both cores and mines are taken to determine the treatment that must be performedprocess of Coal Washing Considering the fact of requirement of millions of tones clean coal for the endusers, mainly power houses, this problem will have to be solved effectively The benefits of low ash coal burning in boilers are realized but reimbursement of extra cost of beneficiation for washed noncoking coal needs to be consideredCoal Beneficiation Technology for Coking NonCoking Even today, traditional coal beneficiation is performed using coal washing with large amounts of water It is then necessary to expend considerable energy drying the coal again Moreover, in many regions of the world water is rare, and it is becoming more difficult for mines to obtain licenses for its useDry coal preparation without the use of water • STEINERTCoal mining can be an extremely profitable trade to go into This is largely because coal is a natural resource provided by the Earth that has been excavated for what seems like a very long time Coal mining as we know it today would not be possible if it were not for dedicated coal beneficiation []Coal Washing Plant Over The Years Coal Washing Plant Jul 14, 2017 Coal washing The raw coal extracted out from the coal mine is processed through different techniques to achieve the desired qualities These result in higher economic value of run ofmine (ROM) coalBasic knowledge about coal preparation

COAL BENEFICIATION IIM

Raw coal fed on to the vibrating bed having crosswise and vertical slope Air supplied through air holes in the beneficiation bed which agitates the raw coal resulting in stratification of coal as per its relative densities lighter coal forms the upper layer and heavier coal forms the lower layer Upper good coal Coal Washing Mined coal is of variable quality and is frequently associated with mineral and chemical material including clay, sand, sulphur and trace elements Coal cleaning by washing and beneficiation removes this associated material, prepares the coal to customer specifications and is an important step in reducing emissions from coal useCoal Use and the Environment WCAThe results of the floatsink tests showed that the most convenient washing operating density was 16 g/cm3, and the weight yield of the clean coal was 5316%wt (7094% coal recovery) with 1646% (PDF) An optimization study of yield for a coal washing Coal washing engineers could list the following reasons: 1 What is the capacity? By different scales of washing coal, the investment budget varies a lot, do you understand? 2 Either be completely washing or lumpcoal washing? The investment budget varies a lot, do you understand? 3How Much Does It Cost To Build A Coal Washing Plant? NewsCoal characteristics related to beneficiation is then covered, followed by a chapter on sulphur in coal and the reactions of sulphur functional groups that would lead to sulphur removal The washing of coal, physical cleaning of fine coal and chemical desulphurization of fine coal are then covered} place = {Netherlands} year = {1982} month Fundamentals of coal beneficiation and utilization (Book

Coal preparation plant Wikipedia

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or shipsCoal Washing And Beneficiation COAL BENEFICIATION cmpdiareas will have to use washed coal with ash not exceeding 34% Fine Coal Beneficiation Mechanized mining operations have brought about Coal Beneficiation Power Line Magazine Jul 09, 2017 An important aspect with regard to coal washing is the partial washing of noncoking coal Under this Coal Coal Washing And BeneficiationOptimization of Coal Beneficiation Plants for $02 Carnegie Mellon Many different types of processes are used for washing coal, including jigs, concentrating tables, dense medium ves sels, cyclones, and froth flotation devices Read moretypes of jigs used in coal beneficiationJul 09, 2017 An important aspect with regard to coal washing is the partial washing of noncoking coal Under this, less than 13 mm particles are left unwashed and only over 13 mm coal are washed The washed product (from +13 mm washing) is then blended with unwashed coal to obtain an overall ash content of 34 per cent in coalCoal Beneficiation Power Line MagazineCoal Washing is a process of separation mainly based on difference in Specific Gravity of Coal and associated impurities like Shale, Sand Stones etc so that we get relatively pure marketable coal without changing its physical properties The Washed Coking Coal is meant for Steel PlantsCoal Beneficiation Technology for Coking NonCoking Coal

Fundamentals of coal beneficiation and utilization (Book

Coal characteristics related to beneficiation is then covered, followed by a chapter on sulphur in coal and the reactions of sulphur functional groups that would lead to sulphur removal The washing of coal, physical cleaning of fine coal and chemical desulphurization of fine coal are then coveredJul 14, 2017 Coal preparation includes blending and homogenization, size reduction, grinding, screening and handling The most important step is coal beneficiation or cleaning The cost of coal preparationBasic knowledge about coal preparationJul 27, 2020 Floatsink tests are done on samples of coal from beds that will likely need washing (beneficiation, preparation) to remove sulfur or ash (rock and mineral matter) from the coal to meet the desired specifications of the end userThe floatsink analysis determines how much coal can be separated from rock and minerals in fluids of different densitiesFloatSink (Washability) Test, Coal Analysis, Kentucky Coal Washing And Beneficiation COAL BENEFICIATION cmpdiareas will have to use washed coal with ash not exceeding 34% Fine Coal Beneficiation Mechanized mining operations have brought about Coal Beneficiation Power Line Magazine Jul 09, 2017 An important aspect with regard to coal washing is the partial washing of noncoking coal Under this Coal Coal Washing And BeneficiationCoal cleaning by washing and beneficiation removes this associated material, prepares the coal to customer specifications and is an important step in reducing emissions from coal useCoal Use and the Environment WCA

Beneficiation an overview ScienceDirect Topics

Coal preparation or coal beneficiation comprises a number of actions to treat ROM coal to ensure a consistent quality and to enhance its suitability for particular enduses With the increasing usage of lignite and subbituminous coal (both classified as LRC), reducing the level of intrinsic moisture either by application of drying technologies Dec 01, 2011 „ Washing may be viable for pithead power stati o ns als o whe n us e o f washe d coa l lead s t o substantial improvement of PLF and for power plants running at part load due to deterioration in coal Mineral Processing Technology : GLOBAL COAL BENEFICIATION