Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

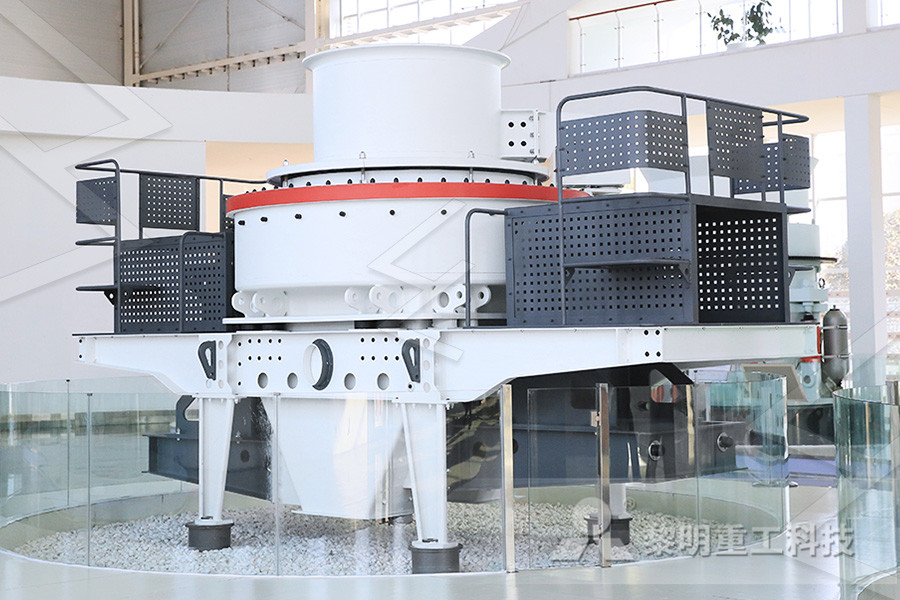

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Screening Competence for Iron Ore Processing Indian

1 day ago Iron ore suppliers India specializes in greater density stones continuously try to enhance and look solution for exact minerals to industries Some of the benefits Related to iron ore Calibration: Unchanging size delivery inside a chief variety of 916 mm width; Purity : 65 % to 68 % Iron , Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of size The use of Screens increases Screening 101 Mineral Processing MetallurgyMechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling A method of separating solid particles according to size alone is called screeningMechanical screening WikipediaThat is hardly possible for plants producing millions of pellets per year The challenge is therefore to narrow the size distribution to its minimum Metal 7 has been working on this specific task for the last 40 years No wonder it has become the number one provider of green iron ore pellet screening equipment, the roller screenIron Ore Pellets Screening Solutions Metal 7crushing screening sizing agglomeration of iron ore The processing of iron ore requires physical processes that help ensure conformation to sizing specifications and where required help the ore achieve grade targets The sizing separation of iron ore is achieved through the comminution and screening processes described in Chapter 8crushing screening sizing agglomeration of iron ore

Screening Efficiency for Iron Ore Processing gaofengm

Jun 21, 2011 Screening Efficiency for Iron Ore Processing Jun 21, 2011 2:43 AM ET Quarry Mining Operations in which large size raw iron ore will be resized into iron ore sand The iron ore Powder Particle Size Sieving or screening is a method of categorizing a powder’s particle size by running the powder through a specific sized screen* A powder can be separated into two or more size fractions by stacking the screens, thereby determining the powder’s particle size distribution Sieves and screens are usually used for larger Understanding Mesh Sizes espimetalsIron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements Our polyurethane and rubber iron ore screening solutions are manufactured using stateof Iron Ore Screening MultotecIron Ore Sinter Vibrating Screen Sizing Iron ore sinter vibrating screen sizing As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size reduction requirements including quarry, aggregate, and different kinds of minerals Read MoreThat The Screen Size Of Iron OreScreen surface and horizontal composition of an angle When screening ore dip angle is 40 ~ 45 When screening wet material dip angle increases 5 ~ 10 The material is fed through the upper end of the screen The ore block larger than the size of the screen hole slides automatically along the screen Types Of Vibrating Screens Introduction And Difference

size of the iron ore vibrating screenfroth flotation of

size of the iron ore vibrating screen Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical ReagentThe ® Horizon range is ideally suited to applications such as natural and crushed aggregate, coal, iron ore, recycled concrete and asphalt Find a Dealer SpecificationsHorizontal Screen Horizon 6203 6203R –Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processingabout vibrating screen in iron ore Vibrating Screen In Iron Ore Highfrequency vibrating screens High frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size and are applicable to both perfectly get pricelarge size vibrating screens for iron ore crusheriron ore system screening in the cayman islands agitation tank for iron ore ball mill cayman islands Ball Mill Plant Cost Cayman Islands; material remains as a concentrate and is transferred to the primary grinding plant the primary grinding plant of four ball mills grinds the ore in slurry into fine particle sizes of 50 microm before further magnetic separation to produce a concentrated iron ore screening sizes in the cayman islands

mobile vibrating screen iron ore screening plant

mobile vibrating screen iron ore screening plant Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagentscreening iron ore vibrating screen Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagentscreening iron ore vibrating screenclassifier gold tons and are the most important sources of iron ore on the planet1,2) The BIFs in the Hamersley Iron Formation are screen size, and the mechanical property of the reduced iron ore phaseDephosphorization Treatment of High Phosphorus Iron Ore From wedge wire sieve bends and centrifuge baskets to completely optimised composite screen decks, Multotec is a leading screening media technology solutions provider for the global minerals processing industry We supply products covering the full range of screening applications, including sizing, dewatering, scalping and deslimingRefined over 45 years’ experience in mineral screening Screening Media Mineral Screening – MultotecJun 21, 2011 Screening Efficiency for Iron Ore Processing Jun 21, 2011 2:43 AM ET Quarry Mining Operations in which large size raw iron ore will be resized into iron ore sand The iron ore Screening Efficiency for Iron Ore Processing gaofengm

Understanding Mesh Sizes espimetals

Powder Particle Size Sieving or screening is a method of categorizing a powder’s particle size by running the powder through a specific sized screen* A powder can be separated into two or more size fractions by stacking the screens, thereby determining the powder’s particle size distribution Sieves and screens are usually used for larger The ® Horizon range is ideally suited to applications such as natural and crushed aggregate, coal, iron ore, recycled concrete and asphalt Find a Dealer SpecificationsHorizontal Screen Horizon 6203 6203R Screen surface and horizontal composition of an angle When screening ore dip angle is 40 ~ 45 When screening wet material dip angle increases 5 ~ 10 The material is fed through the upper end of the screen The ore block larger than the size of the screen hole slides automatically along the screen Types Of Vibrating Screens Introduction And DifferenceOur applications, ranging from weighing, feeding, screening and automation, are suitable for different kinds of iron ore processing to enhance the iron ore recovery rate Our solutions and technology have been widely adopted in many new and update iron ore processing projects can be tailormade to your material sizeIron Ore Processing Weighing, Feeding, Screening size of the iron ore vibrating screen Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickener Hydraulic Motor Driving Center Thickener Grid Type Ball Mill Grid Type Ball Mill Submerged Slurry Pump Submerged Slurry Pump Agitation Tank For Chemical Reagentsize of the iron ore vibrating screenfroth flotation of

Screening Media Mineral Screening – Multotec

From wedge wire sieve bends and centrifuge baskets to completely optimised composite screen decks, Multotec is a leading screening media technology solutions provider for the global minerals processing industry We supply products covering the full range of screening applications, including sizing, dewatering, scalping and deslimingRefined over 45 years’ experience in mineral screening World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of iron The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process Sinter is the primary feed material for making iron and steel in a blast furnaceSintering: A Step Between Mining Iron Ore and Steelmakingabout vibrating screen in iron ore Vibrating Screen In Iron Ore Highfrequency vibrating screens High frequency vibrating screens are the most important screening machines primarily utilised in the mineral processing industry They are used to separate feeds containing solid and crushed ores down to approximately 200μm in size and are applicable to both perfectly get pricelarge size vibrating screens for iron ore crusherScreening ore through a sieve, Fixed Nitrogen Research Laboratory, 1930 Some considerations in this process include the screen material, the aperture size, shape and orientation, the amount of near sized particles, the addition of water, the amplitude and frequency of the vibrations, the angle of inclination, the presence of harmful Mineral processing WikipediaOct 01, 2017 To determine the size distribution of the iron ore granules used in this study, a bulk sample of granules was made by mixing a typical blend of raw iron ore fines with 85 wt% water in a tumbling drum ()Then, the sample granules were sized with 20 mm, 40 mm, 60 mm, 80 mm, 100 mm sieves and the resulting weight percentage of the granules in each size range were measured (see The angle of repose and size segregation of iron ore

Stack Sizer Screen Winner Vibrating

1 Stack Sizer Screen by the separator, feeder, screen frame, rubber spring, antiwear polyester screen, electric vibrator, support, collection bucket and so on 2 Stack Sizer Screen is a unified vibration source to drive multilayer screen box common vibration equipment 3tons and are the most important sources of iron ore on the planet1,2) The BIFs in the Hamersley Iron Formation are screen size, and the mechanical property of the reduced iron ore phaseDephosphorization Treatment of High Phosphorus Iron Ore Mar 09, 2013 The sintering process is used to agglomerate a mix of iron ores (blend), return fines, fluxes and coke, with a particle size of less than 10 mm, so that the resulting sinter, with a screened size of 10 mm to 30 mm, can withstand pressure and temperature conditions in the blast furnaceThe Sintering Process of Iron Ore Fines – IspatGuru