Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

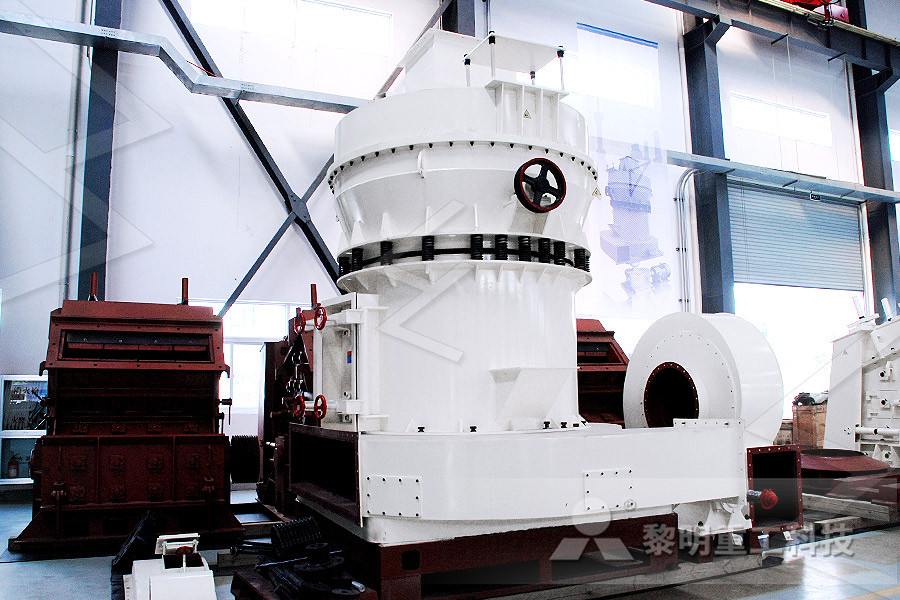

Vertical Roller Mills

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingVertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plantsVertical Roller Mill In Cement IndustryWhen grinding cement products, a grinding system composed of a roller press or an external circulation vertical mill + a powder concentrator + a tube mill is generally selectedCement Grinding Machine Selection: Vertical Roller Mill VS In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated cement Ball Mills Or Vertical Roller Mills: Which Is Better For Vertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world It is ideal equipment for superfine milling industry which integrated with crushing, drying, grinding and collectingVertical Grinding Mill, Vertical Roller Mill Powder Making

HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills

With scientific reasonable design and its unique advantages, HLM vertical roller mills are applied widely in power, metallurgical, cement, chemical and nonmetallic industry, for grinding of various materials, such as cement raw material, clinker, limestone, slag, manganese, gypsum, coal, barite, calcite etcHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills Cement Industry LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology Our designers are constantly coming up with new ideas and even more dependable components to reduce the already acclaimed low failure rate of our millsCement Industry LoescheFig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including Vertical roller mill for raw Application p rocess materialsApr 01, 2010 Grinding trends in the cement industry Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %Grinding trends in the cement industry Cement Lime Gypsum

Vertical Roller Mill In Cement Industry

Vertical roller mills, especially those common for grinding of cement raw materials, typically employ a hydraulicpneumatic system to apply a grinding force to the material bed During operation, these systems will contain pressurized hydraulic fluid in an isolated branch of the circuit consisting principally of cylinders and accumulatorsGrinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisationWith scientific reasonable design and its unique advantages, HLM vertical roller mills are applied widely in power, metallurgical, cement, chemical and nonmetallic industry, for grinding of various materials, such as cement raw material, clinker, limestone, slag, HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process Descriptions Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindingsVertical roller mill for cement grinding

HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process Fig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including Vertical roller mill for raw Application p rocess materialsOct 11, 2019 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a Vertical roller mills: The new leader in grinding technologyNigeria: Loesche has released details on its order for the United Cement Company of Nigeria (Unicem) cement plant at Mfamosing, near Calabar in Cross River State, which was commissioned in September 2016 The order was for two vertical roller mills (VRM): one type LM 604 for grinding cement raw material and one LM 704+4 CS, the biggest Loesche VRM built for grinding cement clinkervertical roller mill Cement industry news from Global CementSummary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the Grinding trends in the cement industry Cement Lime Gypsum

Shree Cement orders vertical roller mills from Gebr

Nov 17, 2020 A MVR 6000 R6 type raw mill will grind 800t/hr of raw material and have a drive power of 8700kW Gebr Pfeiffer said, “The grinding rollers of this mill can be equipped with roller tires for raw meal grinding as well as for cement grinding, provided that they have been designed according to the same force moduleVertical Roller Mill In Cement Industry Over the last three decades the vertical roller mill has be widely used in cemment industry The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemVertical Roller Mill In Cement IndustryVertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill productionVertical Roller Mill,Verical Roller Mill TypesJun 11, 2018 The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical airswept grinding mills dates back to Ernst Curt Loesche’s invention In 1927, he applied for a patent for the world’s first springloaded airswept mill – the beginning of the triumph that is LOESCHE vertical roller millsLOESCHE Mill Series LMCS Revolutionises the Cement IndustryNowadays, the cement grinding system has developed from the previous single ball mill system to ball mill + roller press system and vertical roller mill system Today we will introduce three mainstream ball mill + roller press cement grinding processes that are often adopted in cement plants and cement grinding stationsBall Mill Roller Press Systems for Cement Grinding

Performance Evaluation of Vertical Roller Mill in Cement

Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedCEMENT GRINDING IN A VERTICAL ROLLER MILL Ball Mill This page is about the cement grinding in a vertical roller mill, which include roller design, structure of cement millCement Roller Mill Crusher Mills, Cone Crusher, Jaw CrushersGrinding vertical roller mill for cement industry,for sale To design a successful Grinding Vertical Roller Mill is Grinding Vertical Roller Mill Spare Parts Grinding Vertical Roller Mill Features The whole plant Vertical Roller Mill Parts In Cement Plants Crusher Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the features of simple structure and low cost of manufacture and use Vertical roller mill has many different forms, but it works basically the samegrinding vertical roller mill for cement industryVertical Roller Mill In Cement Production Plant Vertical Roller Mill GGBS amp Cement Plant cement grinding Nonmetal industry because the overall efficiency attributed to energysaving and low consumption is becoming and evident in the cement industry grm series vertical roller mill is developed with the features of high metallurgy chemical industry The vertical roller mill has been Grinding Mill Of Vertical Roller Mill In Cement Plant

Vertical roller mill for cement grinding

Recently, especially from 1980s, grinding system using the vertical roller mill, which has effective grinding performance, is developed and applied in the cement grinding process Descriptions Basic equipment structure of the vertical roller mill for cement grinding is the same as the vertical roller mill of raw material and coal grindingsFig2 Schematic process flow of vertical roller mill for grinding of raw materials Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including Vertical roller mill for raw Application p rocess materialsVertical Roller Mill In Cement Industry Atox 45 HLM Vertical Roller Mill With scientific reasonable design and its unique advantages HLM vertical roller mills are applied widely in power metallurgical cement chemical and nonmetallic industry for grinding of various materials such as cement raw material clinker limestone slag Optimization Of Vertical Roller Mill In Cement IndustryOct 11, 2019 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM) For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is still not fully acceptedVertical roller mills: The new leader in grinding technologyVertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use VRMs for cement grinding However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classification and regrinding Vertical roller mill optimisation

Quality Vertical Cement Mill Cement Ball Mill factory

Strong Drying Capacity Vertical Cement Mill Low Noise 100mm Max Feeding Size; 18KW Cement Ball Mill For Cement Grinding High Milling Efficiency Steadily Running; 185 125kw Vrm Vertical Cement Mill For Cement Clinker Grinding Station; Chemical Industry 200T/H Vrm Cement Mill For Raw Coal; Water Slag Coal Grinding 6000tpd Vertical Cement MillHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying; It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification; Coal vertical mills can work in openair environments, greatly reducing the cost of investment The design of the vertical coal mill system is simple Vertical Coal Mill for Coal Grinding in Cement Plant