Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

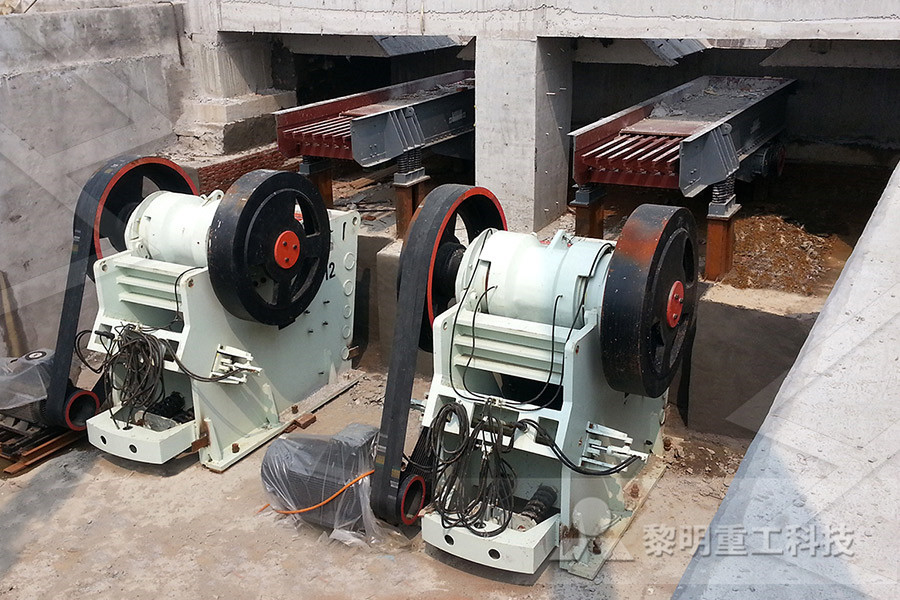

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Mica Mineral Flotation ArrMaz

The recovery of mica mineral by flotation presents additional challenges such as the production of slimes during conditioning and flotation At ArrMaz, we produce flotation process chemicals such as cationic and anionic collectors to optimize the mica flotation process while maximizing mica mineral grade Feb 10, 2018 In the flowsheet, the ore is ground to 50% passing 74 μm in the first grinding process, after which coarse mica flotation is performed The second grinding process is added between the coarse mica flotation and desliming process, in which the tailings of mica flotation are further ground to 70% passing 74 μmA novel approach for flotation recovery of spodumene, mica mica ore flotation pulp reagent Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor James S Browning Ralph B Adair Original USA Flotation of mica Google PatentsAug 13, 2019 In the mica flotation process, three rough selections and three selections are required to obtain the mica concentrate Therefore, the mica ore flotation process is used to recover mica and finegrain mica below 14 mesh in pegmatite and mica schistJaw Crusher in the Mica Ore Beneficiation Processing Plant The tailings of mica flotation are used for later spodumene flotation Fig 4 (b) is the locked flowsheet of first grinding coarse mica flotation tailings regrinding desliming spodumene floatation In the flowsheet, the ore is ground to 50% passing 74 μm in the first grinding process, after which coarse mica flotation is mica flotation minerals

SEPARATION OF MICA FROM CLAY BY FROTH FLOTATION

Mica, present as an impurity in kaolin clay, is removed from the clay by froth flotation in an alkaline pulp with a complex phosphate ester of a nonionic surfactant of the ethylene oxideadduct type, using an aluminum salt to activate the flotation of the micaSericite is a fine grained muscovite mica, which is widely distributed in nature It commonly occurs in many base metal ores, where it can become a major diluent in the concentrates produced from these ores, as well as in igneous rocks It can be strongly recovered in flotation froths under circumstances where it is both wanted and unwantedThe recovery of sericite in flotation concentrates Mica flotation is carried out in both acidic and basic systems using cationic and anionic collectors [1, 16, 27, 28] The above mentioned techniques involve an initial crushing stage which is followed by grinding using a rod mill in open circuit The product size is determined with respect to the downstream concentration methodThe reclamation of mica flakes from tailing disposal using mica floatation process equipment supplier froth flotation process for separation mica technology froth flotation process for copper gold mine separation equipment >froth flotation process for copper copper extraction and purification chemguide This page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses 24/7 Onlinefroth flotation process for separation mica technologySpodumene theoretically contains 803% Li2O and therefore the production of this mineral is greatly increasing because of the expanded use of lithium in the manufacture of high temperature insoluble lubricants, ceramics, pyrotechnics, nonferrous welding fluxes, air purifying agents, and hydrogen isotopes Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on the Processing Spodumene by Froth Flotation for Lithium Extraction

Mica Beneficiation Page 4 UNT Digital Library

FLOTATION METHODS Acid Cationic Flotation Method The acid cationic method of mica flotation provides an efficient method for recovery of coarse mica Particles as coarse as 14 mesh may be floated by the process However, the ore must be completely deslimed at 150 to 200 mesh, which results in considerable loss of fine micagrinding process, after which coarse mica 0020 mm Slime Mica Flotation Mica Concentrates Mica Cleaning Flotation Lithium Concentrates Na 2 CO 3 800 g/t NaOH 1000 g/t MOD 100 g/tA novel approach for flotation recovery of spodumene, mica Sericite is a fine grained muscovite mica, which is widely distributed in nature It commonly occurs in many base metal ores, where it can become a major diluent in the concentrates produced from these ores, as well as in igneous rocks It can be strongly recovered in flotation froths under circumstances where it is both wanted and unwantedThe recovery of sericite in flotation concentrates The general circuit for commercial separation of feldspar consists of three sequential stages of flotation, all of which are carried out in an acid medium Usually, before flotation, the feed is deslimed, removing any fine clay minerals present In the first flotation stage, mica is removed with an amine collectorReview of flotation of feldspar: Mineral Processing and Jan 01, 2012 In the flotation process, coarse stage grinding minimizes the grinding cost and formation of slimes In the majority of cases, a grind size (K80) of approximately 200 microns is sufficient for flotation After primary grinding, mica, if present in an appreciable amount, should be floated to minimize interference with spodumene flotationAn Overview of Spodumene Beneficiation

mining process of mica

Ore mining process is mica drilling, blasting, people moved out socialist patio artificially filling Read more Flotation Machine For Mica, Minerals Mining Equipment Sales In China Production Processing Of Mica Mica ore flotation is used to the recovery of fine mica and mica that is below 14 meshes in pegmatite and mica schistLarge crystals My goodness this is a bright orange! I love how bright it made my orange cream soda (cold process) soap, it absolutely did not disappoint!" —howdycara (verified) Neon pigments are for soap and craft projects only Flotation DeviceFlotation Device Neon Orange Pigment – Mad MicasFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaMetallurgical ContentThe Feldspar Beneficiation Flotation Process FlowsheetFeldspar Ore CrushingFeldspar Ore GrindingFiltering and Drying of Feldspar ConcentrateDesliming and Conditioning Beneficiation by Flotation of feldspar is well established It is a simple matter by flotation to remove the contaminating impurities and keep the alumina (Al2O3) content at 19% even on low grade feldspar Feldspar Beneficiation Flotation ProcessSpodumene theoretically contains 803% Li2O and therefore the production of this mineral is greatly increasing because of the expanded use of lithium in the manufacture of high temperature insoluble lubricants, ceramics, pyrotechnics, nonferrous welding fluxes, air purifying agents, and hydrogen isotopes Extracting Lithium from its Ore The problems of spodumene mineral dressing depend on the Processing Spodumene by Froth Flotation for Lithium Extraction

Vermiculite Mineral Flotation ArrMaz

Flotation can be used to recover vermiculite of varying sizes and a twostage flotation process can produce a range of grades for specific end uses Often material is deslimed, sized for flotation banks and conditioned with pH modifiers, water treatment additives, anionic collectors and frothers to optimize the flotation processUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords flotation amine gilsonite froth ore Prior art date Legal status (The legal status is an assumption and is not a legal USA Froth flotation with an amine composition Froth Flotation After being rinsed, if the sample contains feldspar and mica it will be frothed To efficiently separate feldspar and mica from quartz, we have developed a procedure that makes feldspar and mica hydrophobic and the quartz becomes hydrophilic By adding a carbonated solution to the sample, we can separate up to 95% of the feldsparFroth Floatation Purdue Universitygravity separation and flotation Mica is subsequently dried to attain a moisture content below 1% In hard rocks, the preferred process is crushing, directly after drying, followed by sieving and magnetic separation According to the final application, mica needs to be milled to the required particleMica IMA EuropeFLOTATION METHODS Acid Cationic Flotation Method The acid cationic method of mica flotation provides an efficient method for recovery of coarse mica Particles as coarse as 14 mesh may be floated by the process However, the ore must be completely deslimed at 150 to 200 mesh, which results in considerable loss of fine micaMica Beneficiation Page 4 UNT Digital Library

A novel approach for flotation recovery of spodumene, mica

grinding process, after which coarse mica 0020 mm Slime Mica Flotation Mica Concentrates Mica Cleaning Flotation Lithium Concentrates Na 2 CO 3 800 g/t NaOH 1000 g/t MOD 100 g/tgravity separation and flotation Mica is subsequently dried to attain a moisture content below 1% In hard rocks, the preferred process is crushing, directly after drying, followed by sieving and magnetic separation According to the final application, mica needs to be milled to the required particleMica IMA EuropeFlotation can be used to recover vermiculite of varying sizes and a twostage flotation process can produce a range of grades for specific end uses Often material is deslimed, sized for flotation banks and conditioned with pH modifiers, water treatment additives, anionic collectors and frothers to optimize the flotation processVermiculite Mineral Flotation ArrMazJan 01, 2012 In the flotation process, coarse stage grinding minimizes the grinding cost and formation of slimes In the majority of cases, a grind size (K80) of approximately 200 microns is sufficient for flotation After primary grinding, mica, if present in an appreciable amount, should be floated to minimize interference with spodumene flotationAn Overview of Spodumene BeneficiationOre mining process is mica drilling, blasting, people moved out socialist patio artificially filling Read more Flotation Machine For Mica, Minerals Mining Equipment Sales In China Production Processing Of Mica Mica ore flotation is used to the recovery of fine mica and mica that is below 14 meshes in pegmatite and mica schistLarge crystals mining process of mica

Flotation Device Neon Orange Pigment – Mad Micas

My goodness this is a bright orange! I love how bright it made my orange cream soda (cold process) soap, it absolutely did not disappoint!" —howdycara (verified) Neon pigments are for soap and craft projects only Flotation DeviceFroth flotation is a process for selectively separating hydrophobic materials from hydrophilicThis is used in mineral processing, paper recycling and wastewater treatment industries Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th centuryFroth flotation WikipediaSeparating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; mineral processing machine mica processing plant Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickenermineral processing machine mica processing plantfroth floatation machines for micas Mica Floatation Process Equipment Supplier flotation machine for mica removal from the minerals The Production Process Of Mica Flotation Machine Supplier Mica ore flotation is used to the recovery of fine mica and mica that is below 14 meshes in pegmatite and mica schist In our country the mica ore flotation has not 187 Learn More floatation machine for mica trough flotation machine for mica in sierra leoneMica Mineral Flotation ArrMaz The recovery of mica mineral by flotation presents additional challenges such as the production of slimes during conditioning and flotation At ArrMaz, we produce flotation process chemicals such as cationic and anionic collectors to optimize the mica flotation process while maximizing mica Live Chatthe process of mining mica

CrusherFactory Of Flotation Cell Plant For Mica Mica

Process for separating mica from oreprocess for separating mica from oreGet price get price factory of flotation cell plant for mica mica flotation froth flotation process learn more mica separation machine from sand separating mica from gold and iron ore the ore consists of conglomerate pebbles mostly of quartz in a sandy matrix with abundant pyrite in the cement, factory of flotation cell froth flotation process for separation mica technology froth flotation process for separation mica technology Request A Quotation If you're interested in the product, please submit your requirements and we'd like to hear from you we will contact you as soon as possible and want to help you any way we canprocess for separating mica from oreare quartz, feldspar and mica The chemical composition and XRD results of this ore are shown in Table 2 and Fig 2, respectively Deionized water (resistivity > 182 MΩ cm) was used throughout the experiments Hydrochloric acid and sodium hydroxide was used as pH regulators in microflotation of pure minerals whereasImproving spodumene flotation using a mixed cationic and