Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

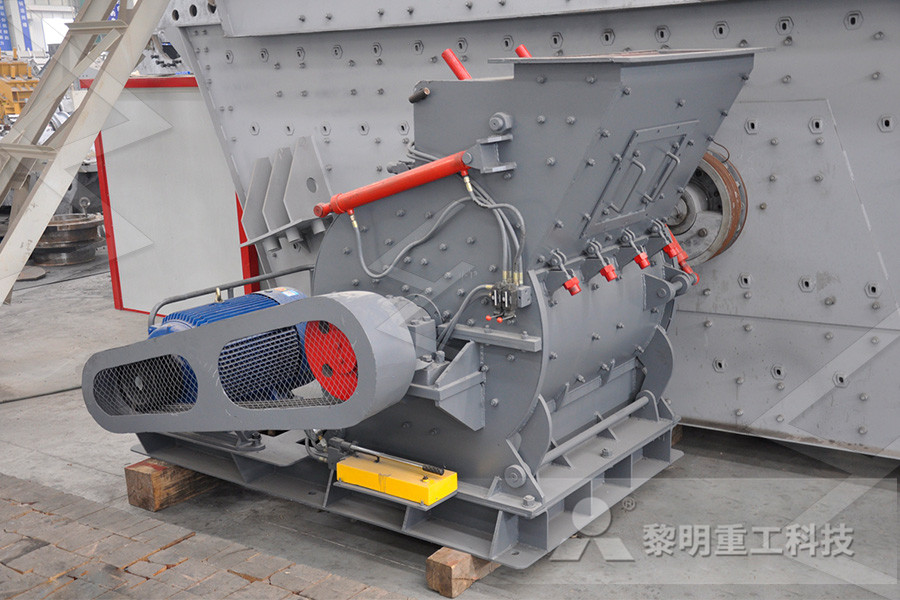

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

new gold ore processing technology pdf

Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be The development of copper ore processing technology cannot be separated from the support of equipment Because the grade of copper ore is lower than that of iron ore and the processing capacity of copper ore is larger, largescale, energysaving and highefficiency processing equipment is a way to improve the grade of copper concentrate and economic benefit of copper mineCopper ore processing technology development 01022021 Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy BritannicaOre processing technology is very proficient at the crushing, screening and grinding of iron ore, manganese ore, gold ore and copper ore etc Meanwhile, can help many domestic and foreign plants customize and upgrade the main machines; Ore processingsolutions Industrial The development of copper ore processing technology cannot be separated from the support of equipment Because the grade of copper ore is lower than that of iron ore and the processing capacity of copper ore is larger, largescale, energysaving and highefficiency processing equipment is a way to improve the grade of copper concentrate and economic benefit of copper minecopperoreprocessingtechnologydevelopment

Manganese Ore Dressing Processing Technology

Manganese ore processing technology is based on its different principles, there are many methods, now in China magnetic concentration is the most widely used in manganese ore processing technology, after rough concentration and selected concentration then get the concentrate It is a high technological enterprise that integrated research, manufacture, sales and service Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different equipment for processing of ore vaarbewijsshopnl10042014 Toss Plasma Technologies (TPT), a company based in the US, has developed a new radio frequency (RF) plasma technology by which complex ores such as zinc, nickel, copper and lead are heated applying ultrahigh temperatures of between 8,00012,000 degrees Celsius to break down the ore structure and free up the latent precious materials contained therein for recovery and purification using Ten technologies with the power to transform miningAt present, the common tin ore processing processes mainly include gravity separation, flotation and magnetic separation, that is, the raw ore is washed and deslimed, crushed and screened, preselected, and then processed by one or more classification equipment such as gravity separators, flotation cells, magnetic separators, etc, and finally obtain the ideal grade and recovery of tin concentrateInventory of Tin Ore Processing Technology and Manganese Ore Processing Technology Our company is a heavy industry enterprise committed to producing heavy mining machinery Mainly producing and selling machines like jaw crusher, ball mill, sand maker, sand washing machine, mobile crushing plantProcessing Technology Manganese Ore

Ore Processing Technology Newtridentrp Wiki

Ore processing Technology is a procedure in which raw minerals are extracted and processed into useful components Researching this technology allows the construction of Ore Processor, Orbital Ore Processor Station and Deep Space Ore Processor Station01022021 Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyMineral processing metallurgy BritannicaManganese ore processing technology and beneficiation equipment 1 Ore washing and screening Ore Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore from the mud Common Equipment ore washing screen, drum washing trommel machine and trough ore Manganese Ore Processing Technology and ORE PROCESSING TECHNOLOGY LIMITED Learn more about ORE PROCESSING TECHNOLOGY LIMITED Check the company's details for free and view the Companies House information, company documents and list of directorsORE PROCESSING TECHNOLOGY LIMITED Free Aluminum processing Aluminum processing Ores: Aluminum is the third most abundant element on Earth’s surface Only oxygen and silicon are more common Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic formAluminum processing Ores Britannica

Finnish ore processing technology eyed for local

04042019 The Department of Science and Technology (DOST) has tagged a Finnish ore processing technology being used in New Zealand that can enable the Philippines to manufacture steel out of its abundant Dewatering is an important process in mineral processing The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangueMineral processing WikipediaOre processing technology is very proficient at the crushing, screening and grinding of iron ore, manganese ore, gold ore and copper ore etc Meanwhile, can help many domestic and foreign plants customize and upgrade the main machines; Ore processingsolutions Industrial The technology aims to improve the recovery of iron ore still contained in wastes or low grade ROM making it possible to obtain iron ore concentrate with 68 per cent iron, and ultimately providing New dry iron ore processing technology Toss Plasma Technologies (TPT), a company based in the US, has developed a new radio frequency (RF) plasma technology by which complex ores such as zinc, nickel, copper and lead are heated applying ultrahigh temperatures of between 8,00012,000 degrees Celsius to break down the ore structure and free up the latent precious materials contained therein for recovery and purification using Ten technologies with the power to transform

Ore Processing Technology Newtridentrp Wiki

Ore processing Technology is a procedure in which raw minerals are extracted and processed into useful components Researching this technology allows the construction of Ore Processor, Orbital Ore Processor Station and Deep Space Ore Processor StationProcessing technology of weak magnetic iron ore Single weakly magnetic iron ore, including sedimentary metamorphic, sedimentary, hydrothermal and weathered deposits of hematite, siderite, limonite and hematite (specular iron)siderite ore, etc The production practice of this kind of ore beneficiation is lessIron ore processing technology,gravity separation Manganese ore processing technology and beneficiation equipment 1 Ore washing and screening Ore Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore from the mud Common Equipment ore washing screen, drum washing trommel machine and trough ore Manganese Ore Processing Technology and Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing Ores BritannicaOre is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding Ore processing – Waihi Gold

Aluminum processing Ores Britannica

Aluminum processing Aluminum processing Ores: Aluminum is the third most abundant element on Earth’s surface Only oxygen and silicon are more common Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic formORE PROCESSING TECHNOLOGY LIMITED Learn more about ORE PROCESSING TECHNOLOGY LIMITED Check the company's details for free and view the Companies House information, company documents and list of directorsORE PROCESSING TECHNOLOGY LIMITED Free The development of a completely new ore processing technology designed exclusively for your Plant (as designed or existing plant), your ore, your specifications and tasks Research work The development performed by two professionals experienced in the field of mineral processing with the scientific degree of The development of a new ore processing 04042019 The Department of Science and Technology (DOST) has tagged a Finnish ore processing technology being used in New Zealand that can enable the Philippines to manufacture steel out of its abundant Finnish ore processing technology eyed for local Toss Plasma Technologies (TPT), a company based in the US, has developed a new radio frequency (RF) plasma technology by which complex ores such as zinc, nickel, copper and lead are heated applying ultrahigh temperatures of between 8,00012,000 degrees Celsius to break down the ore structure and free up the latent precious materials contained therein for recovery and purification using Ten technologies with the power to transform