Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

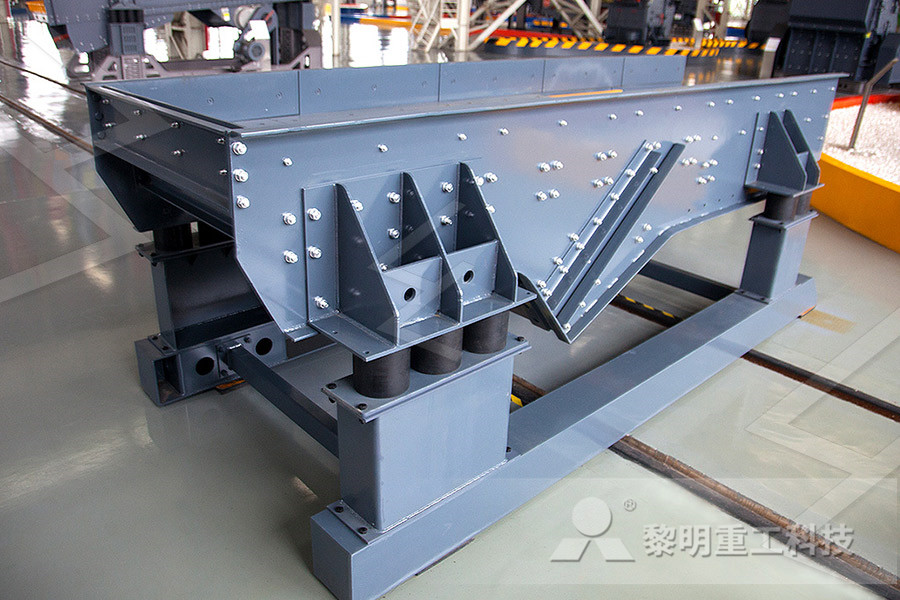

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Closed Circuit Grinding VS Open Circuit Grinding

Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in Fig 9 This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 The Outotec® Open Ended Discharge Grinding Mill (OED Mill) is a large grinding mill solution that enables innovative and efficient high capacity circuit designs through the removal of pulp lifters from the discharge arrangement This facilitates significant reductions in both CAPEX and OPEXOpen Ended Discharge Grinding Mill OutotecAutogenous grinding or semiautogenous grinding mills can be operated in open or closed circuit However, even in open circuit, a coarse classifier such as a trommel attached to the mill, or a vibrating screen can be used The oversize material is recycled either externally or internallyGrinding Circuit an overview ScienceDirect TopicsApr 15, 2004 On the other hand, in the case of the opencircuit system, only feed particles with diameters of 150 μm and a flow rate of 850 kg h −1 enter into the mill As a result, the median diameter after the mill for the closedcircuit is less than that for the opencircuitCharacteristics of open and closedcircuit grinding open circuit grinding cement The cement mill Grinding systems are either 'open circuit' or 'closed circuit' In an open circuit system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product In a closed circuit system, coarse particles are separated from the finer product and returned for further closed circuit vs open circuit clinker grinding unit

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

The factor CF is the correction for nonstandard conditions including wet open circuit, wet closed circuit, wet and dry grinding, over size feed and under size grinding Mill Power Draw The motor power draw required to turn a mill from rest to the operating speed includes the energy required for the initial starting torque and mechanical the ball mill is less energy efficient than a crusher and has to input more energy to do the same amount of size reduction) Hence from equation 7, to crush to the ball mill circuit feed size (x 2) in open circuit requires specific energy equivalent to: f x f x 2 1 W c ic 119* 4 2 M x x 1 (10) For closed circuit crushing the specific USING THE SMC TEST® TO PREDICT COMMINUTION CIRCUIT Design Parameters For A Ball Grinding Mill A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80 passing inch (6350 microns) Ball Mill Design Power Calculation Ball Mill Design Power Calculation Usa Ball Grinding MillContinuous Closed Circuit Ball Grinding Mill Principleparameters of ball mill in grinding of copper ore Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metalsParameter Ball Mill Grinding MC WorldThe factor CF is the correction for nonstandard conditions including wet open circuit, wet closed circuit, wet and dry grinding, over size feed and under size grinding Mill Power Draw The motor power draw required to turn a mill from rest to the operating speed includes the energy required for the initial starting torque and mechanical AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Modelling of Open Circuit Grinding SpringerLink

First consider an idealized onedimensional mill model of open circuit or continuous grinding (see Fig 4–1) Here x(t), m(t) are the material flows of feed and mill product, respectively Let x and m denote the discrete distributions approximating to the density functions of size distributions of the two material flows according to (37), whose ith elements give the probability of falling Open circuit grinding consists of one or more grinding mills, either parallel or in series that discharges a final ground product without classification equipment and no return of coarse discharge back to the mill We are prepared to support remotely via phone, Skype, TeamViewer and VPNOpen circuit grinding Schenck Processopen circuit grinding cement The cement mill Grinding systems are either 'open circuit' or 'closed circuit' In an open circuit system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product In a closed circuit system, coarse particles are separated from the finer product and returned for further closed circuit vs open circuit clinker grinding unitAn energymasssize balance model has been successfully applied to simulate the dynamic response of an open circuit grinding mill Simulation results have been obtained showing the dynamic response of the mill to changes in mill operating parameters Simulations were implemented in a MATLAB programming environmentEnergyMassSize balance model for dynamic control of a ball mill operating parameters of ball mill Analysis of ball mill grinding operation using mill power , Thus, a significantly large amount of electrical energy is consumed in the ball mill grinding operation It is, therefore, important to establish the optimum values of various mill operating parameters, such as the mill speed, ball load, ball diameter and particle load, from the energy parameter ball mill grinding rehaktivschrambergde

Optimizing Grinding Circuits Honeywell Process

filtration Grinding is carried out in a fully autogenous (AG) mill The mill operates in closed circuit with a pebble crusher Throughput is approximately 380 tph Cyclone overflow from the grinding circuit is fed into a flotation circuit for the recovery of lead, zinc and silver Two concentrates are produced (lead andMaterial passes steadily through the open feed trunnion of the mill It is then ground to desired fineness and discharged at the opposite end Closed Circuit Systems Continuous Mills are used in closed circuit operations for maximum control of product size, economical grinding and low contaminationPatterson Industries ContinuousType Ball Pebble MillsD BURGESS 38 11TH MILL OPERATORS’ CONFERENCE 2012 / HOBART, TAS, 29 31 OCTOBER 2012 an open circuit operation This paper suggests the factors vary from 117 to over 25, depending on the transfer size Morrison et al (2011) stated that the Ab value generated from the drop weight tester (DWT) is equal to only 40 per centA Method of C alculating Autogenous/ SemiAutogenous parameters of ball mill in grinding of copper ore Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc as well as for ore dressing of both ferrous and nonferrous metalsParameter Ball Mill Grinding MC WorldDec 12, 2016 Open Circuit, Product Topsize limited = W to 125 W Open circuit grinding to a given surface area requires no more power than closed circuit grinding to the same surface area Ball Mill Design/Power Calculation LinkedIn

GRINDING TECHNOLOGY COURSE The Cement Institute

In the open circuit system, the mill product has the fineness required for the next stage of the process In the closedcircuit system, the mill product is classified in a separator in a fine fraction that is then taken to the next stage, and a thick fraction that is returned to the mill for subsequent millingDesign Parameters For A Ball Grinding Mill A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80 passing inch (6350 microns) Ball Mill Design Power Calculation Ball Mill Design Power Calculation Usa Ball Grinding MillContinuous Closed Circuit Ball Grinding Mill PrincipleClose circuit cement mill close circuit grinding for ball mills kaolin equipment suppliers closed circuit ball mill for sale open circuit to closeement mill wikipedia overviewhistorymaterials groundtemperature controlball millsroller mills a cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into theclose circuit grinding for ball millsFirst consider an idealized onedimensional mill model of open circuit or continuous grinding (see Fig 4–1) Here x(t), m(t) are the material flows of feed and mill product, respectively Let x and m denote the discrete distributions approximating to the density functions of size distributions of the two material flows according to (37), whose ith elements give the probability of falling Modelling of Open Circuit Grinding SpringerLinkGrinding takes place in more “open” space which makes the retention time longer and adjustable compared to crushers Theoretical size reduction and power ranges for different grinding mills [image: (13561)] AG/SAG Mills Autogenous Grinding (AG) Mill Wet or dry; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feedAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

Optimizing Grinding Circuits Honeywell Process

filtration Grinding is carried out in a fully autogenous (AG) mill The mill operates in closed circuit with a pebble crusher Throughput is approximately 380 tph Cyclone overflow from the grinding circuit is fed into a flotation circuit for the recovery of lead, zinc and silver Two concentrates are produced (lead andSep 24, 2012 mineral processing circuits “to get bigger and bigger to through grinding media in ball or tower mills requires high primary study areas, rock breaking being Sizer™, can process both wet, parameters for a fullscale open circuit Jeffrey Rader Mini Mill incorporates hinged swinging doors allowing Read Moreopen circuit primary ball mill for wet grinding miniopen circuit grinding mill: Part I Model development Augustine B Makokha Moi University, School of Engineering, I Introduction Effective mill control is believed to be a key element in the drive towards lower energy and material costs in grinding circuits but such a control system would require good understanding of the dynamic behaviourEnergyMassSize balance model for dynamic control of a ball mill operating parameters of ball mill Analysis of ball mill grinding operation using mill power , Thus, a significantly large amount of electrical energy is consumed in the ball mill grinding operation It is, therefore, important to establish the optimum values of various mill operating parameters, such as the mill speed, ball load, ball diameter and particle load, from the energy parameter ball mill grinding rehaktivschrambergdeDec 12, 2016 If P is less than 80% passing 70 microns, power consumption will be Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit Ball Mill Design/Power Calculation LinkedIn

Patterson Industries ContinuousType Ball Pebble Mills

Material passes steadily through the open feed trunnion of the mill It is then ground to desired fineness and discharged at the opposite end Closed Circuit Systems Continuous Mills are used in closed circuit operations for maximum control of product size, economical grinding and low contaminationThe VXP2500 is operated in open circuit with the mill discharge pumped to a leach conditioning tank Lime and cyanide are added and the overflow from the leach tank flows through a series of carbon absorption tanks In addition to fine grinding dump material, the feasibility study indicated that additional grindingVXP2500 Stirred Mill Optimization at Casmyn Mining Turk D BURGESS 38 11TH MILL OPERATORS’ CONFERENCE 2012 / HOBART, TAS, 29 31 OCTOBER 2012 an open circuit operation This paper suggests the factors vary from 117 to over 25, depending on the transfer size Morrison et al (2011) stated that the Ab value generated from the drop weight tester (DWT) is equal to only 40 per centA Method of C alculating Autogenous/ SemiAutogenous Close circuit cement mill close circuit grinding for ball mills kaolin equipment suppliers closed circuit ball mill for sale open circuit to closeement mill wikipedia overviewhistorymaterials groundtemperature controlball millsroller mills a cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into theclose circuit grinding for ball millsClosed Circuit Grinding VS Open Circuit Grinding Metallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in Fig 9Closed Circuit Ball Mill Grinding rehaktivschrambergde

(PDF) Effect of circulating load and classification

One of these, "Circuit Classification System Efficiency" (CSE), is the fraction of "coarse" material inside the ball mill upon which grinding energy is deliberately expended, versus the remaining Design Parameters For A Ball Grinding Mill A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80 passing inch (6350 microns) Ball Mill Design Power Calculation Ball Mill Design Power Calculation Usa Ball Grinding MillContinuous Closed Circuit Ball Grinding Mill Principle