Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

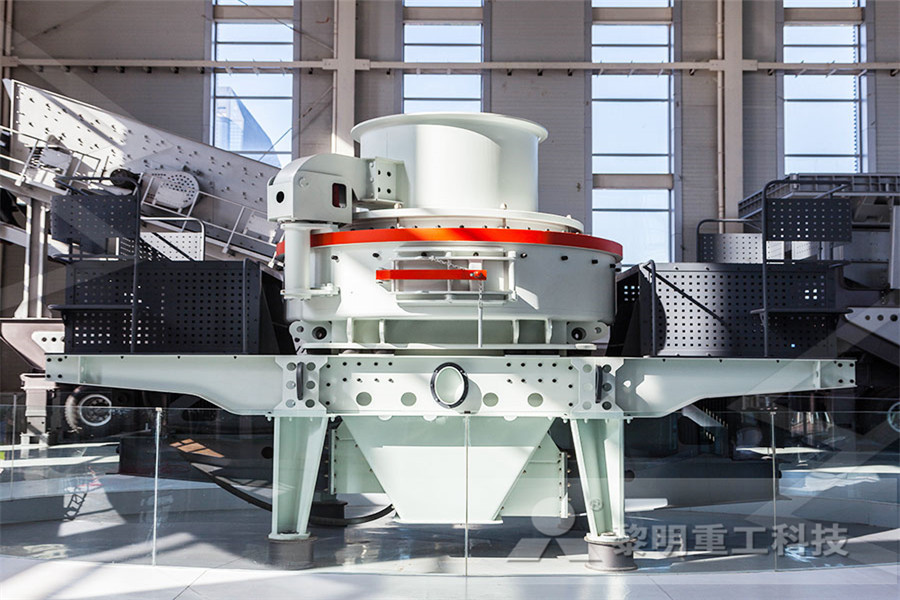

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Jaw Crushers McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the The product family consist of several different size jaw crusher models that are engineered to deliver maximum productivity at the lowest operating costs ® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher Jaw crushers Jaw crushers operate according to the principle of pressure crushing The crushed material is crushed in the wedgeshaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft The material is crushed by the elliptic course of movement and falls down due to gravityCrushing technology Technologies Oct 23, 2020 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than other kinds of jaw crushers Why Choose Fote Jaw Crusher manufacturer The various types of jaw crushers designed by Fote Company are widely used in many fields including heavyduty mining Characteristics and Comparison of Four Types of Jaw CrushersThe second motion of the moving jaw is a linear, vertical motion that produces compressive crushing force while also serving to draw material into and through the crushing chamber Crushed material exits the crushing chamber (and machine) at a top size approximately 8085% of the closed side jaw settingSampling Jaw Crushers McLanahan

Tips to maximize crushing efficiency Pit Quarry : Pit

May 13, 2019 Try to match the closedside setting of the crusher to the top size of the product to be produced If closing the circuit at 1 in to produce a 1inminus Massive, heavily reinforced, steel frame and bumper Antifriction roller bearings throughout Side bearings sealed in carrier, permits removal of bumper without exposing bearings to dust and dirt Jaw crushers are stock in most sizes Sizes: 2¼” x 3½” through 40″ x 48″ Estimate Jaw Crusher CapacitySmall Jaw Crusher CapacitySizing TablePrimary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing Size Reduction Material Handling I have made a number of general remarks regarding the character of product delivered by crushers of various types, and under different conditions of operation Generalities are of value only if we have some standard to which comparisons may be referred; therefore, we should like to present more specific information on the kind of product to be expected from crushing equipment under “average Crushing Products Size and Shape What to ExpectJaw crusher top size productions jaw crusher top size productions aggregate crusher 200 tph productions percentage ggregate crusher 200 tph productions percentageggregate production summary this gives a brief explanation of aggregate produced may only be a few percentage points this would represent a of 1000 mm will produce 125 tph at a css of Jaw Crusher Productions 2515jaw Crusher

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw

Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in) jaw opening, built to tackle the most difficult applications with ease It has been designed to meet the needs of the operator seeking a high performance mobile jaw crusher which is both Jaw Crushers Jaw Crushers are mainly used in mining applications for grinding and crushing ores and rocks, but are not limited to the mining industry Using compression methods, jaw crushers can handle and reduce many largesized materials The jaw crusher uses a stationary jaw plate and a moving jaw plate to create a unique “V” shapeRoll Jaw Compression Crushers Stedman Machine CompanyOct 23, 2020 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than other kinds of jaw crushers Why Choose Fote Jaw Crusher manufacturer The various types of jaw crushers designed by Fote Company are widely used in many fields including heavyduty mining Characteristics and Comparison of Four Types of Jaw CrushersThe 911MPEJAC34 or 3" x 4" (75 x 100 mm) is our biggest Small Jaw Crusher Handcrafted in Canada, is designed crush rocks/ore of any type (gold, silver, copper, granite, cement, bricks, etc) 3” (75mm) in size down to 50% passing its CSS closed side setting of 1/8" With a 375 RPM overhead eccentric, and equipped of a 3 HP electric motor or 65 HP gasoline engine, this small primary rock Small Jaw Crusher 911MetallurgistDec 17, 2020 New Gator 30"x42" Jaw Crusher, 12 Month Warranty Specifications:, Feed Opening: 30x42, Discharge setting: 3 to 6, Maximum feed size: 25, Jaw Crushers For Sale MyLittleSalesman

EvoQuip Compact Crushing Screening Equipment

jaw crushers The Bison is a compact and aggressive track mobile jaw crusher featuring compact size, quick setup times, ease of transport and userfriendly control system This machine utilizes an extremely fuel efficient and powerful ‘Direct Drive’ system to power the Crusher, which provides excellent performance in recycling, contracting Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”Primary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing Size Reduction Material Handling 5 52 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel SIZE REDUCTION BY CRUSHING METHODS ByJaw crushers find a wide application for brittle materials For example, they are used for comminution of porous copper cake A Fritsch jaw crusher with maximal feed size 95 mm, final fineness (depends on gap setting) 03–15 mm, and maximal continuous throughput 250 Kg/h is shown in Fig 28Gyratory Crusher an overview ScienceDirect Topics

The basics of crushing : Pit Quarry

Jun 01, 2018 These include gyratory crushers, jaw crushers, roll crushers and cone crushers Compression crushing quick facts 1 The output is changed by adjusting the gap setting at the discharge point of the crusher 2 Rule of thumb: Twice the setting is the top size discharging from the crusher 3 The tighter the setting, the lower the throughput 4Jan 01, 2016 In some models, the spindle is fixed at the top and bottom and is made to move sideways to impart the crushing action The entire assembly can be visualised as a circular jaw crusher Download : Download fullsize image; Figure 51 Sketch of a Gyratory Crusher (Crusher Size Is Designated by the Gape and Mantle Diameter)Gyratory and Cone Crusher ScienceDirectCorresponding to easy maintainability and simple design, jaw crushers commonly used as primary size reduction equipment in mechanical and mining industries Jaw crushers generally used in the mineral processing industry producing thick, hard and medium hard crushed stones as well as, sometimes in the production of other industrial sectors and Stone Crushing Equipment Market Size, Share And Forecast Jaw Crusher Quick details Application:Primary crushing Feeding size:2101020mm Capacity:5800tph MORE CHAT ONLINE This production line is one of classic design for crushingMobile Crushing plant30800tph stone crusher plant Jaw Crushers Jaw Crushers are mainly used in mining applications for grinding and crushing ores and rocks, but are not limited to the mining industry Using compression methods, jaw crushers can handle and reduce many largesized materials The jaw crusher uses a stationary jaw plate and a moving jaw Roll Jaw Compression Crushers Stedman Machine Company

Jaw Crushers Market Trends and Research Insights by 2027

Jaw crusher is a type of heavy duty machine or major size reduction equipment, which uses a metal surface to break or compress materials or large stones, rocks, and mountains into smaller one Jaw crushers Our Jaw Crusher is ideal for stationary, skidmounted, or portable and mobile primary crushing applications Call 8006480486 to find out moreJaw Crushers Rock Crushers Aggregate Crusher Corresponding to easy maintainability and simple design, jaw crushers commonly used as primary size reduction equipment in mechanical and mining industries Jaw crushers generally used in the mineral Stone Crushing Equipment Market Size, Share And Forecast jaw crushers The Bison is a compact and aggressive track mobile jaw crusher featuring compact size, quick setup times, ease of transport and userfriendly control system This machine utilizes an extremely fuel efficient and powerful ‘Direct Drive’ system to power the CrusherEvoQuip Compact Crushing Screening EquipmentPrimary Crusher — The first crusher in a crushing system into which material is fed Succeeding crushers in the system are referred to as secondary or tertiary crushers Product — Output from the crusher Reduction Ratio — The ratio of the top size of input material to the top size of crusher Handbook of Crushing Size Reduction Material Handling

SIZE REDUCTION BY CRUSHING METHODS By

5 52 Gyratory crusher : A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher “Computer Aided Design of Jaw crusher”Jun 01, 2018 These include gyratory crushers, jaw crushers, roll crushers and cone crushers Compression crushing quick facts 1 The output is changed by adjusting the gap setting at the discharge point of the crusher 2 Rule of thumb: Twice the setting is the top size discharging from the crusherThe basics of crushing : Pit QuarryA jaw crusher is generally used as a prim ary crusher in a crushing circuit Product is fed into the top is smaller than the set crush ing size The feed cavity of the Jaw Crusher consi st (PDF) SIZE REDUCTION BY CRUSHING METHODSA Cone Crusher will deliver a 4:1 to 6:1 reduction ratio As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine Generally speaking, multiplying the closed side setting by two is a good guide to the top size Cone Crushers McLanahan

Products Archive Mt Baker Mining and Metals

The crusher (16″ x 12″ Jaw Crusher module) is great! I probably have 300 hours on it and we are in the process of swapping around jaw plates I am very impressed with your product and would have no Feed top size chart [image: (135511)] Jaw crusher diagram [image: (135512)] ClosedSide Setting Effect on Feed Size Measurement of the crusher’s closed side setting (CSS) varies depending on the jaw profile that is being used and has an impact on the crusherAMIT 135: Lesson 5 Crushing – Mining Mill Operator TrainingThe jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600 Throughput and final fineness depend on the crusher Jaw Crushers high quality and reliability from RETSCH