Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

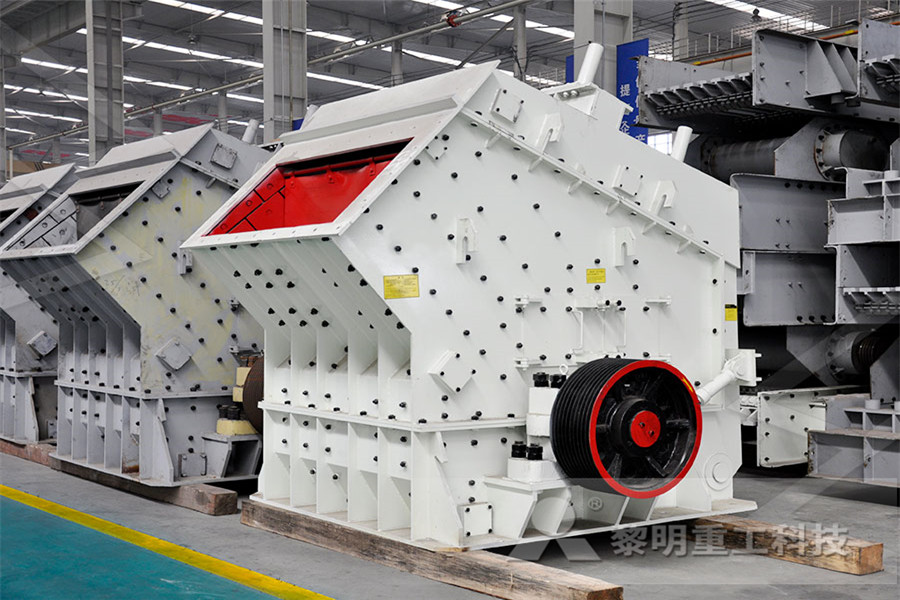

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How it Works: A Feed Mill Plant 3D Animation Bir Yem

Jul 10, 2017 3d animation istanbul, 3d modeling and design, plant animation, machinery animation, machine working running animations3d animasyon istanbul, 3d modelleme Operations Drawing Of Feed Mill Plant Complete documentation of feed milling plants skiold a/s Then comes startup of the feed mill, training of the operational staff, and final the complete plant, and the involved parties get full and comprehensive drawingOperations Drawing Of Feed Mill PlantPlant capacities both current and future must be determined to make sure key systems will handle all capacity levels Summary The process flow of the mill must be defined and drawn before any physical layout of the mill is started Provision for future equipment and systems must be included in initial mill design Title: Feed Mill DesignFeed Mill Design SA Trade HubWhether planning to build a new feed processing facility or remodeling or upgrading an existing facility, many things must be considered, like: Ease of operation , material handling flow: Plant layout design plays an important part in the design and engineering phases of any industrial facilityFeed Mill Design Layout Lark Engineering Feed Mill Many projects I work on are simple, such as a client ing me a hand sketch that I use to create a 3D model to get the client accurate estimating information, or ing me a scanned set of old paper drawings of a feed mill, seed cleaning plant, or grain elevator to be replicated in digital 2D or 3DDesign, Layout, Engineering of Grain, Feed, Seed Plants

How to make feeds with big feed mill plant? modern animal

Jan 08, 2019 How does this feed pellet line works? Firstly, choose suitable raw materials to make feed pellets, such as maize, soya bean meal and etc Secondly, grind theThe stateoftheart Feedstock Processing Research Facility, or Feed Mill, provides the quality, nutritional value and precision mixing of feeds needed to sup port internationally recognized CFAES livestock and poultry research programs The ability of Feed Mill staff to produce specialty diets according to exact specifications onsite boosts the quality of research and gives scientists a Feed Mill Agricultural OperationsFeed formulation and operation of the pellet mill may be balanced to supply fish with a feed that is acceptable, available, and easily digested The interdependent variables present in ingredient selection are subjects for research in each area of fish culture and for each fish speciesChapter 18 Feed Milling Processesprevent feed contamination and provide reasonable assurance that the feed is manufactured accurately These guidelines serve as Food and Drug Administration (FDA) regulations Everyone involved in producing medicated or nonmedicated feed, whether at a commercial offfarm plant or at an onfarm mill or grinder/mixer, must comply with the GMPsMF2041 Preventative Maintenance for Feed Processing Examples of plant layout and design Principles of plant layout and design will apply to most industrial situations The following layout examples encompass a wide variety of facility characteristics, and of process characteristics Readers, this is the most popular page on jacksonproductivity Thanks for your interest, and I hope you'llExamples of plant layout and design Jackson Productivity

Feed Mill Design Layout Lark Engineering Feed Mill

Whether planning to build a new feed processing facility or remodeling or upgrading an existing facility, many things must be considered, like: Ease of operation , material handling flow: Plant layout design plays an important part in the design and engineering phases of any industrial facilityMay 07, 2018 For mills that only make a few formulas, the efficiency factor might be increased to 90% or more Assuming the capacity rates required in Table 1 are for a commercial feed mill, making numerous different formulas, the design capacity rate would be 60 tph/80 = 75 tph We will use this design capacity in several places in future articlesFeed Operations: Planning a new feed mill Worldgrain Feed formulation and operation of the pellet mill may be balanced to supply fish with a feed that is acceptable, available, and easily digested The interdependent variables present in ingredient selection are subjects for research in each area of fish culture and for each fish speciesChapter 18 Feed Milling ProcessesOperations Presenter: Jim Voigt, President, JFV Solutions Inc Outline – feed and flour mills, feeders Processor Feed Mill Miller Feeder Operational procedures of a grain elevator 1) 1) your current plant and /or company policies and programsGrain Operations Webinar SeriesNov 05, 2019 Koch Foods said the new poultry feedmill will create 28 new jobs with an annual payroll of $1 million The Attalla facility, designed with technologically advanced features for maximum efficiency, will support the company’s recently expanded processing plant in nearby GadsdenKoch Foods to expand Alabama operations with new Attalla

Feed Mills / Feed Yards / Pre Mix Plants Comco

To be successful, modern feed mills must be as efficient as possible Margins and production schedules are tight It is critical to choose the right automation partner in this environment Feed producers need a partner who can provide a state of the art system and can be relied upon to provide the longterm service and support that is requiredExamples of plant layout and design Principles of plant layout and design will apply to most industrial situations The following layout examples encompass a wide variety of facility characteristics, and of process characteristics Readers, this is the most popular page on jacksonproductivity Thanks for your interest, and I hope you'llExamples of plant layout and design Jackson Productivityplants represent average costs for the United States A feed plant in a par ticular area or region may have higher or lower costs Revision of earlier developed models reflects the trends and practices of the feed manufacturing industry as indicated by equipment manufacturers, feed mill construction firms, and members of the mixed feeds industryFEED MANUFACTURING COSTS AND CAPITAL REQUIREMENTSFeed Manufacturing and Process Control – Overview/Objective • Maintaining consistent control over the quality and safety of the finished product requires applying quality assurance procedures at each step of the feed manufacturing process Procedures have been developed for: – Grinding operations – Batching and mixing operationsFeed Quality Assurance Programs for Feed MillsNatural toxins, including toxic plants d Heavy metals e Minerals f Unapproved feed ingredients g Unapproved food additives (3) Physical a Stones b Wood c Metal d Glass e Plastic (e) Each establishment will evaluate the following areas to determine the potential effect of each on the possible adulteration of the feed and/or Feed Industry Hazard Analysis and Critical Control Point

A Sample Livestock Feed Mill Business Plan Template

It is for this reason that a sample livestock feed mill business plan template has been prepared below; A Sample Livestock Feed Mill Business Plan Template 1 Industry Overview The economic value of animal agriculture in the united states of America is very huge as it has provided more than 23 million jobs for the economy The monetary value In the latter case there would be, unless you put the feed mill under separate management, a danger of its operation becoming too important a component of the farm manager's responsibilities Also, professional advice would be essential in designing the feed manufacturing plant, selecting and installing equipment, and training staff to operate it5 CAN I MAKE MY OWN COMPOUND FEEDS? HOW?Dec 09, 2020 This operation is done in case of bolt ends and shaft ends Chamfering helps to avoid damage to the sharp edges and protect the operation getting hurt during other operations Chamfering on bolt helps to screw the nut easily Knurling operation: It is an operation of obtaining a diamond shape on the workpiece for the gripping purposeLathe Machine Operations [Complete Guide] with Picture PDFWe devote ourselves to undertaking all poultry feed production line 120T/H and to providing more value added service to all the customers (1)Determine the scale of poultry feed mill (2)Determine the feed process and recommend poultry feed machine (3)Control mode selection (4)Poultry feed manufacturing plant structure selectionPoultry Feed Production LineLoChamp Group(Flow chart, Different unit operations in milk processing with the help of flow charts, Know how to draw the flow charts and plant layouts) FLOW CHART A flow chart is a representation of sequence of operations in a processing plant or in a process For example, if we want to prepare dried vegetables, the sequence of operations will bePROCESS FLOW CHARTS AND PLANT LAYOUT FLOW CHART

FEED MILL MANUFACTURING TECHNOLOGY

• Feed manufacturing plant trainees • Feed industry sales and technical service Course Goals 1 Learn about feed industry and feed mill operation and management 2 Understand the concepts governing feed mill design and operation 3 Lean about the types of equipment used in a commercial feed manufacturing plant 4plants represent average costs for the United States A feed plant in a par ticular area or region may have higher or lower costs Revision of earlier developed models reflects the trends and practices of the feed manufacturing industry as indicated by equipment manufacturers, feed mill construction firms, and members of the mixed feeds industryFEED MANUFACTURING COSTS AND CAPITAL The new feed mill is just south of their existing operations and is made up of a concrete tower standing over 180 feet tall, surrounded by preengineered metal buildings for storage and operations The facility is notable for more than just its size, boasting a hitech operating system with the ability to work with just three main crew Kalmbach Feeds opens stateoftheart feed plant – Ohio Ag Leaching plants, faced with increased tonnage, coarse (up to —3/16″ solids) feed, longer retention time, erosion, corrosion and the high cost of space, must be compact, simple and highly efficient The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also evaluate the design factors which will prevent the settlingout of solids Leaching Plant Design Mineral Processing Metallurgymill operator in the way of knowledge and ability The skill of the pellet mill operator, through his ability or mistakes, influences plant profitability Pellet mill operators have a vitally important role in the manufacture of animal feed They should recognize this responsibility and the great contribution they make to an efficient feed plantThe Pelleting Process CPM

Feed Industry Hazard Analysis and Critical Control Point

Natural toxins, including toxic plants d Heavy metals e Minerals f Unapproved feed ingredients g Unapproved food additives (3) Physical a Stones b Wood c Metal d Glass e Plastic (e) Each establishment will evaluate the following areas to determine the potential effect of each on the possible adulteration of the feed and/or Business Scope: Offer turnkey project plan and equipment for complete animal feed processing plant for poultry, cattle, fish and pet, from designing, equipment manufacturing, factory constructing, comissioning, debugging and onsite operation training Production Output Range: 1~1000,000 tons/year ABC Machinery supplied poultry and cattle feed plant adopts module design which can realize Low Cost Poultry Feed Plant Machinery for sale Project plants within Australia, where free gold exists in the grinding circuits In January 1993 a fullscale plant trial using a 30inch manual discharge Knelson concentrator was commissioned In February 1993, the gravity plant was decommissioned and all new feed to th e dore plant now comes from the Knelson THE KNELSON CONCENTRATOR: APPLICATION AND Butterball North Division – Live Operations Feed mill, hatcheries, breeder farms, growout farms, path lab Butterball, LLC 938 Millers Chapel Road Goldsboro, NC 27534 9196586743 HR Confidential Fax: 9197512486 Click here for directions Butterball South Division – Live Operations Feed mill, growCompany Locations Butterball®The development of the roller mill in the 1870’s started the growth of the modern flour mill and the consolidation of the flour milling industry In 1870 there were over 23,000 flour mills in the United States In 2002, there were estimated to be only 336 operating flour mills, with a total of 11,460 employees (US Census Bureau, 2007)Design Considerations for the Construction and Operation

Poultry Feed Mill Equipment POULTRY FEED FORMULATION

A feed production mill is a must have if you are planning to make your own poultry feeds at home or in a small industrial plant Feed milling equipment consists of various components These include the feed grinding machine, a feed mixing machine, the feed pellet machine, the feed A typical layout of a mill using the kraft chemical pulping process is shown in figure 21 Mechanical, semichemical, and sulfite pulp mills differ in detail, particularly in wood preparation, fiber separation, and bleaching, but many of the downstream refining, bleaching, and papermaking processes are similarThe Pulp and Paper Making Processes Princeton UniversityGrain handling facilities include grain elevators, feed mills, flour mills, rice mills, dust pelletizing plants, dry corn mills, facilities with soybean flaking operations, and facilities with dry grinding operations of soycake Train all workers for the specific hazardous work operations they are to perform when entering and working inside Grain Handling Overview Occupational Safety and Health