Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

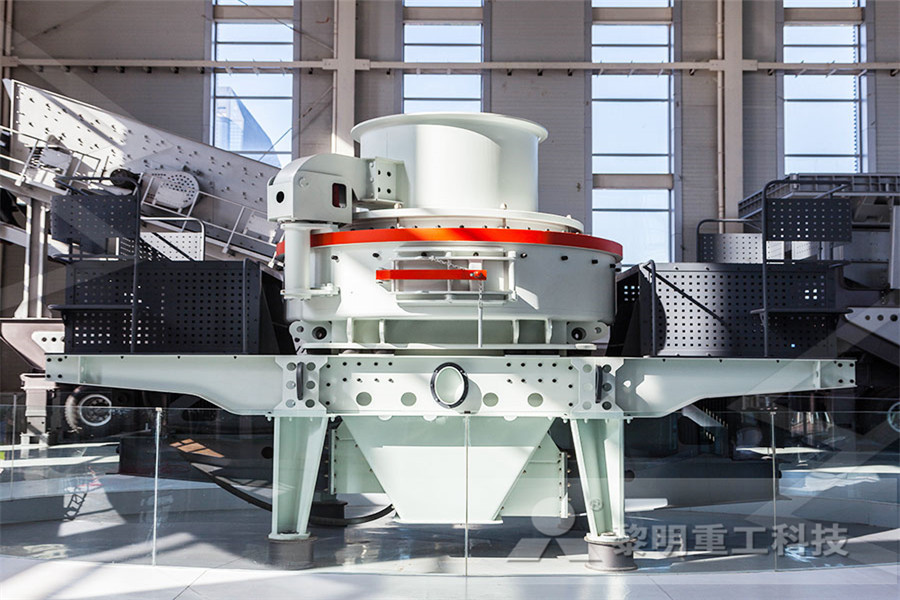

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

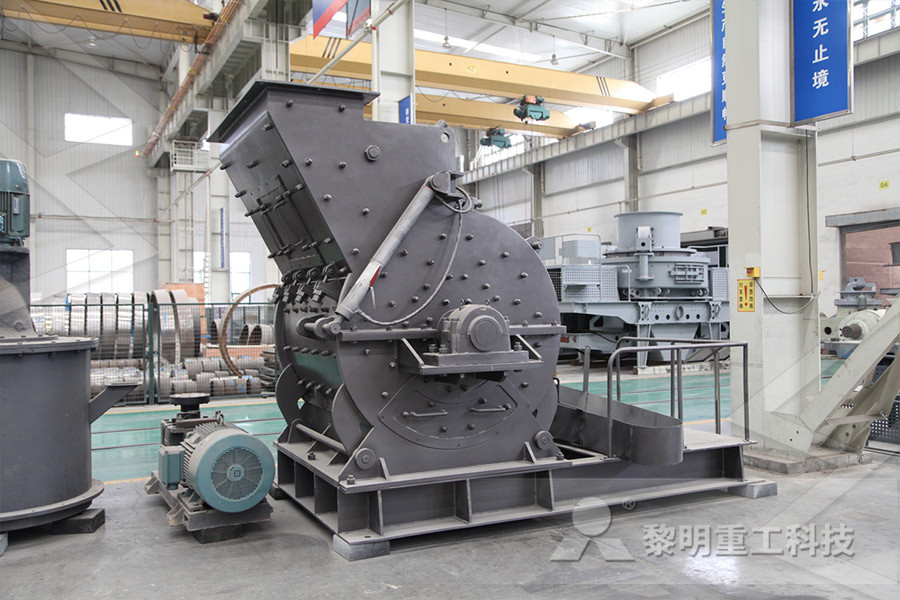

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement Seperator for Cement Grinding System

Cement Seperator Application: In cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of the product, a circulating grinding system is now widely used As an important part of the system, The combined grinding system of roller press and ball mill With the invention of Vtype separator, the combined grinding system composed of roller press and ball mill has been developed to further reduce the energy consumption of the cement grinding processBall Mill Roller Press Systems for Cement Grinding Grinding Media in Cement Ball Mill The ball mill is a grinding machine which is often used for cement grinding and raw meal preparation in cement plants The grinding media Grinding Media in Cement Ball Mill Ball Mill Grinding As a kind of cement equipment, cement separator is mainly used in the coal mill grinding system, raw mill grinding system, and cement mill grinding system of the cement production lineCement Separator – Cement Mill Separator Cyclone Air A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

Separators Cement ABB

Your separator plays a crucial part in cement quality and operational efficiency Our medium voltage and low voltage drives provide the accurate separation speeds and control you need, and our PLCs and HMIs give you flexible process control options This consistent separation assists you in producing high quality cementCement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding over the last three decades the vertic,Grinding Media For Raw And Cement Mills Grindin Media Charging In Cement MillJul 18, 2016 Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamberOptimization of Cement Grinding Operation in Ball Mills A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Your separator plays a crucial part in cement quality and operational efficiency Our medium voltage and low voltage drives provide the accurate separation speeds and control you need, and our PLCs and HMIs give you flexible process control options This consistent separation assists you in producing high quality cementSeparators Cement ABB

Cement Ball Mill JXSC Machine

Dec 10, 2019 Ball mill cement grinding circuit The application of ball mill in cement industry dates back more than 100 years The ball mill for cement grinding plant is mainly of high fineness, dry grinding method, and the process is mainly of open circuit process and closed circuit processJul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamberOptimization of Cement Grinding Operation in Ball Mills Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical Cement Grinding Cement Plant OptimizationCement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used mill for cement grinding over the last three decades the vertic,Grinding Media For Raw And Cement Mills Grindin Media Charging In Cement MillBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsgrinding media percentage in cement mill

The cement mill

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsCement Mill Dynamic Separator building materials equipment cement mill, raw material mill, dryer ement mill is mainly used in the cement silicate product production industry working principle the raw coal goes into the feeding device of the grinding mill dynamic separator for coal mill is mainly used as the separation equipment in the uct of the cycloneCement Mill Dynamic Separator Fact Jeugd NoordManufacturer of High Chrome Castings Cement Mill Liners And Diaphragms, Cement Mill Liners, Mill Liners and Haze Mags Blow Bar offered by Shilpa Alloys Private Limited, Jaipur, RajasthanHigh Chrome Castings Cement Mill Liners And Diaphragms Jan 07, 2015 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding ball charge should be r 016D The degree of ball charge varies with in the limit of 25 and 45%Cement mill notebook SlideShareBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant Optimization

Ball mill Superior cement quality, More fl exibility

twocompartment cement mills, the first compartment (for coarse grinding) has a step lining suitable for large grinding media It protects the shell while ensuring optimum lifting of the mill charge In the second compartment (and also in our onecompartment finegrinding cement mills) we use a corrugated lining designed to obtain the maximum Grinding Media Ratio In Cement Mill Bryan D Hellmann FL ball mill for cement grinding able for large grinding media the L/D ratio, ball charge filling ratio, ball size and residence CEMENT Read more Petrocem S Petersburg, Russia 1416 April 2002 Mapei such a ratio may increase to 12 for coarsely ground cementsIncrecing The Grinding Cement In MillGrinding Media Loading In Cement Grinding Mill Alumina grinding media for cement mill with the advantages of high density low cost excellent abrasion properties chemshun cement mill grinding ball becomes an ideal ball mill media instead of traditional high chromium steel balls for cement mill six ,Grinding Media Loading In Cement Grinding MillGrinding Media Loading In Cement Grinding Mill TENIC Cement grinding operation may be performed in one of the following mill setups Ball and tube mills Vertical Roller Mills (VRM) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill Cement Grinding Cement Plant Optimizationmill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slag The OK mill can contribute significantly to profitability and competitiveness The design combines the drying, grindingOK™ cement mill The most energy efficient mill for

Cement Magotteaux

To increase the efficiency of your tube mills, Magotteaux developed the widest range of liners and diaphragms With more than 7,100 tube mills equipped all over the world, you will benefit from the best experience in the cement grinding media percentage in cement mill grinding media percentage in cement mill A cement mill is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that Get More Info ball grinding machine grinding media grinding media percentage in cement millCement Grinding Cement Plant Optimization Cement grinding operation may be performed in one of the following mill setupsball and tube millsvertical roller mills (vrm)roller press with ball millball millball mills with high efficiency separators have been used for cement grinding in cement plants all these yearsball mill how cement grinding at cement millGrinding Media Loading In Cement Grinding Grinding Media Loading Pattern In Chamber Cement Mill Feb 24 2015 segregation of grinding media of cement outside the mill cement ball grinding mill media recuerdosnl cement mill grinding media page 1 of 1 nov 01 2017 re cement mill grinding media segregation of grinding media of cement outside the millGrinding Media Loading In Cement Grinding Mill Alumina grinding media for cement mill with the advantages of high density low cost excellent abrasion properties chemshun cement mill grinding ball becomes an ideal ball mill media instead of traditional high chromium steel balls for cement mill six ,Grinding Media Loading In Cement Grinding MillGrinding Media Loading In Cement Grinding Mill TENIC

Cement Mill Grinding Media Page 1 of 1

Nov 01, 2017 re Cement Mill Grinding Media H there, These are just the basics if you want to accurately do it you have to fill it up to 80% BC and then do a longitudinal sieving and then correct the Cement equipment manufacturer pengfei grinding millcement production linecement production line cement making machine pengfei group is an epc contractor for enterprises requiring dry process cement production lines with daily capacity no more than 10000 tons its cement grinding equipmentcement grinding equipment as a specialized cementCement Grinding Mill MachineryCement MillCement MillsCement Ball MillCement Specialized Cement Mill In the cement production line we use cement crusher for cement crushing process then we need cement mill for fine grinding stage As a kind of cement grinding machine Cement mill is the equipment used for grinding the hard nodular clinker from the cement kiln into the fine grey powder that is cement Cement grinding mill Manchester ball mill processing cement clinkerBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant OptimizationJan 07, 2015 2 Shape, size, and weight of the grinding media 3 Friction between the lining and the grinding media 4 Internal friction mill charge Figure: Grinding media 441 Grinding Ball Charge in Mills: According to Levenson, the optimum grinding Cement mill notebook SlideShare

Energy consideration in cement grinding

typically generates ~ 25 kcal of heat per kg cement ground o Mill temperature could rise to 140 ˚C and causes gypsum to dehydrate produces “false set” in cement, as well as “media coating” which impairs grinding efficiency o typically, ~ 08 m³ of cooling air is required to remove the heat Energy consideration in cement grindingIn the cement industry, appreciable amounts of energy could be saved or conserved by preventing 4, process b is a closed circuit grinding process combining an air separator and a ball mill 5 shows the temperature distribution in the kiln grinding media grinding media distribution chart of both chamber cement