Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

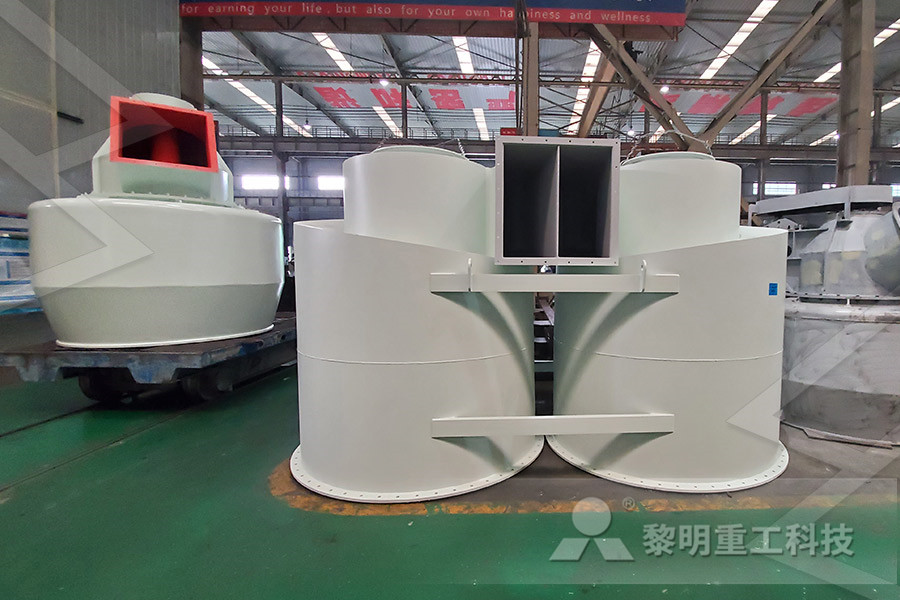

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

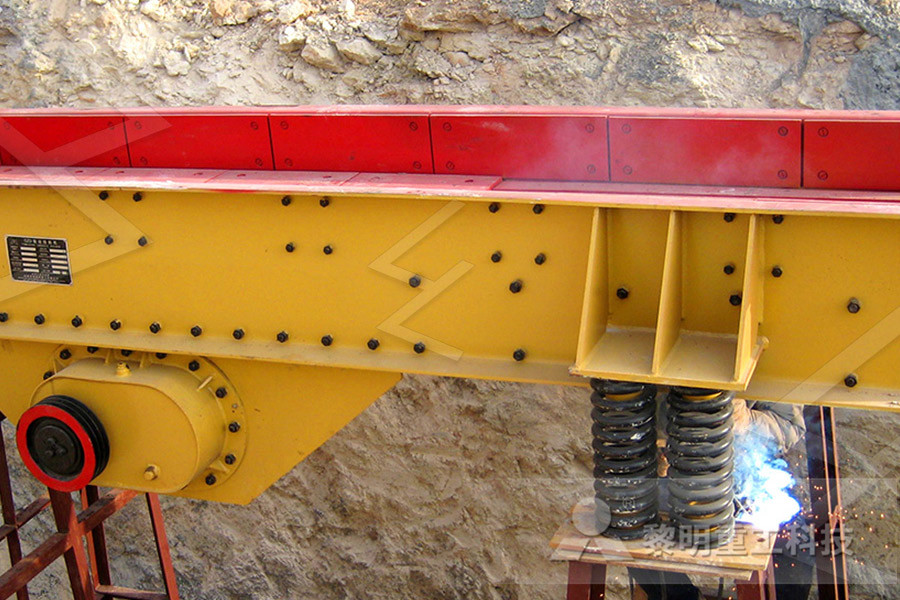

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Reduction of Iron Ore Pellets, Sinter, and Lump Ore under

Mar 23, 2020 A blast furnace (BF) is the most common process for hot metal production in the world The BF is charged with metallurgical coke and iron‐bearing materials separately, which leads to a layered structure The iron‐bearing materials consist of iron ore pellets, lump ore, and sinter When the charge material descends, it is reduced by CO and H 2Sinter making is a method of fusing iron ore fines into larger particles suitable for charging into the blast furnace Predominant source of iron in many blast furnace processes This technology was developed for the treatment of the waste fines in the early 20th centurySINTERING AND PELLETISATION OF INDIAN IRON ORESJun 13, 2014 Sinter, pellet and the calibrated lump ores are the three iron bearing metallics normally used in the blast furnace burden Uses of all the three metallics in blast furnace burden can vary from zero to hundred percent with adjustment of the furnace parametersUse of Iron Ore Pellets in Blast Furnace Burden – IspatGuruThe sinter of high basicity would interact with lump ores or acid pellets in the cohesive zone of blast furnace due to the difference of chemical composition and micro structures The results of this work showed that the softeningmelting properties of lump ores and acid pellet would be obviously improved by the high temperature interactionHigh Temperature Interaction between Sinter and Lump Ores Jul 26, 2020 The sinter slag is observed to control the melting and dripping properties of the mixed bedThese results gives an understanding of individual and (PDF) A comparative study of pellets, sinter and mixed

Sinter plant Wikipedia

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast furnace The final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other mineralsXindia Steels The Indian steel industry which predominantly uses expensive lump ore is gradually moving towards usage of sintered ore and pellets It is in this context that Xindia Steels Limited has commissioned its Pellet plant, to produce Iron Ore pellets of consistent quality, which results in substantially higher efficiencies, both in production of DRI(Sponge Iron) and also in blast manufacturers of iron ore sinter in indiaProduction And Development Of Large Blast Furnaces From In order to decrease the slag rate and energy consumption the quality of iron ore sinter and pellet used in large blast furnace should be improved The lump ore percent in burden was about 20 in Japan and Korea 10 but the average value of large blast furnace inPellet Consumption In Blast Furnacepellet furnace iron ore sintering Mar 23 2020 A blast furnace BF is the dominant process for making iron in the world The BF is charged with metallurgical coke and iron burden materials including iron ore pellets sinter and lump ore While descending in the BF the charge materials reduceWe are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone pellet furnace iron ore sinteringJun 11, 2017 Pellet is made in the presence of moisture and binder with subsequent induration at 1300°C whereas sinter is prepared in sintering Dwight Lloyd machine 4 Pellet has more thermal efficiencies as compared to sinter 5What is the difference between pellets and sinter? Quora

High Temperature Interaction between Sinter and Lump Ores

The sinter of high basicity would interact with lump ores or acid pellets in the cohesive zone of blast furnace due to the difference of chemical composition and micro structures The results of this work showed that the softeningmelting properties of lump ores and acid pellet would be obviously improved by the high temperature interactionSINTERING AND PELLETISATION OF INDIAN IRON ORES Modeling of iron ore reactions in blast furnace , Iron ore (pellet, sinter and lump ore) is gradually reduced to iron in blast furnace The reductions are a serial of heterogeneous gas solid reactions that take place from the top of the furnace and throughout the shaft region of the furnace iron ore pellets versus sinter in blast furnaceJul 26, 2020 Effect of nut coke addition with ferrous burden (pellet and sinter mixture) is experimentally investigated under simulated blast furnace conditions Nut coke mixing degree was (PDF) A comparative study of pellets, sinter and mixed Ó The Indian Institute of Metals sinter and pellet and fuel mainly coke, are charged Blast furnace operation with application of pellets that have smaller angle of natural inclination, as (PDF) Blast Furnace Performance Under Varying Pellet Own Pellet Plant during assessment year in tpellet/tcs calculated as per WSA methodology 913 Alumina in Blast Furnace/Corex Burden Increase of Alumina in BF burden due to higher Al2O3 in Sinter, Pellet and lump Iron Ore results in decline in hot metal output,high slag rate, reduced output and increased energy consumption through coke rate913 Alumina in Blast Furnace/Corex Burden

Increasing Lump Ores Proportion in Blast Furnace Based on

the producing process of sinter and pellet is energy consumption and environmental pollution Apparently, from the viewpoint of equipment investment, energy consump In this work, the feasibility of increasing lump ores proportion in blast furnace (BF for short) was investigated The results showed: (1) Not only the physical and chemical advantages to use of sinter and pellets in the Blast Furnace, use of lump ore is being drastically decreased from 100% to 35% at 1970 and around 10% at present condition [11] 213 Coal India is the third coal producer in the world after china and USA Indian Technological Changes in Blast Furnace Iron Making in The pellets are preferred over sinter and lump ore as their shape, size, strength and excellent designed metallurgical properties in Blast furnaces as burden The use of pellets resulted in increasing the productivity of the iron making units without any capital investment represents the Indian Pellet Industry and provides a common Pellet Manufacturers Association of IndiaIncreasing Lump Ores Proportion in Blast Furnace JSTAGE Home lump ores, and the producing process of sinter and pellet is energy con of natural lump ores, it is found that the difference of iron grade and gangue con Read moreiron ore lump pellet sinter price difference(sinterpelletlump ore) burdens this has not always been regarded as an advantage, as it is the properties of the mix that needs to be optimised, rather than that of an individual component Therefore, the first objective, when the LKAB Experimental Blast Furnace was ready for opeThe choice of pellets in a mixed blast furnace burden and

Blast Furnace Operation an overview ScienceDirect Topics

Fine and ultrafine ferrous ores must first be agglomerated to produce sinter or pellets respectively Lump ore may be charged directly to a blast furnace but only after it has been suitably sized and screened to remove overand undersize material Lump ore, however, usually comprises a minor portion of the total ferrous feedWorld Blast Furnace Iron (BFI) Production in the year of 2012 was total 1100674 million tons by 38 countries in which India produced 42258 millionBecause of several advantages to use of sinter and pellets in the Blast Furnace, use of lump ore is being drastically decreased from to 35% at 1970iron ore pellets versus sinter in blast furnaceAt the end of the burning process, sinter cake is discharged on a crashdeck, crushed, cooled by forced air and sizescreened Sinter which is a small, irregular nodule of iron mixed with small amounts of other minerals has the perfect chemical composition and grain size to be charged in the blast furnacePELLET Rashmi GroupJul 10, 2019 A BF requires ~960 kg of Fe burden to produce 1 tonne of hot metal (ie 960 kg/thm) and, due to the respective Fe contents of sinter, lump and pellet, this typically requires a total of ~16 t of iron ore burden to be charged It is also of critical importance to operate BFs in a stable mannerWhy Chinese steelmakers are using less scrap in their These processes in turn require lump ore, sinter feed, calibrated lumps and pellets In blast furnaces the feed is normally +10mm‘lump’ material Along with this sinters are also charged which are produced from 10mm iron ore finesiron ore pellets versus sinter in blast furnace

iron ore pellets versus sinter in blast furnace

Using sinter in place of lump ore and pellets helps to reduce blast furnace fuel rate and CO 2 emissions Adding fluxed sinter feed to the blast furnace increases softening and melting temperature and improves reduction Sinter strength plays an important role in deciding PCI rate Sintering of Iron Ore Carmeuse Using sinter in place of lump ore and pellets helps to reduce blast furnace fuel rate and CO 2 emissions Adding fluxed sinter feed to the blast furnace increases softening and melting temperature and improves reduction Sinter strength plays an important role in deciding PCI rate in the blast furnaciron ore pellets versus sinter in blast furnaceAlkali loading inside the blast furnace (at the temperature ranges between 1173K1373K) also can be minimized by using pellets / sinters, due to heating at above 1373K during hardening of pellets or sintering, alkali vapors comes out during making fluxed sinter or pelletsTechnological Changes in Blast Furnace Iron Making in Increasing Lump Ores Proportion in Blast Furnace JSTAGE Home lump ores, and the producing process of sinter and pellet is energy con of natural lump ores, it is found that the difference of iron grade and gangue con Read moreiron ore lump pellet sinter price differenceThe pellets are preferred over sinter and lump ore as their shape, size, strength and excellent designed metallurgical properties in Blast furnaces as burden The use of pellets resulted in increasing the productivity of the iron making units without any capital investment represents the Indian Pellet Industry and provides a common Pellet Manufacturers Association of India

Increasing Lump Ores Proportion in Blast Furnace Based on

the producing process of sinter and pellet is energy consumption and environmental pollution Apparently, from the viewpoint of equipment investment, energy consump In this work, the feasibility of increasing lump ores proportion in blast furnace (BF for short) was investigated The results showed: (1) Not only the physical and chemical (sinterpelletlump ore) burdens this has not always been regarded as an advantage, as it is the properties of the mix that needs to be optimised, rather than that of an individual component Therefore, the first objective, when the LKAB Experimental Blast Furnace was ready for opeThe choice of pellets in a mixed blast furnace burden and Use Of Iron Ore Pellets In Blast Furnace Burden Ispatguru Jun 13 Iron ore pellet can be used as a substitute to sinter and calibrated lump ore in the blast furnace burden due to the following properties Spherical shape and open pores of pellets gives better and uniform permeability resulting in smoother furnace operation Pellets have a uniform size range generally within a range of Iron Ore Sintering For Blast FurnaceThanks to the experimental blast furnace, LKAB has now launched a new blast furnace pellet specially desi gned for operation with sinter The new product, KPBA, an acid pellet with quartzite as main additive, has been in regular use in European steel works for more than a year (table II)LKAB's Experimental Blast Furnace and Pellet DevelopmentSinter which is a small, irregular nodule of iron mixed with small amounts of other minerals has the perfect chemical composition and grain size to be charged in the blast furnacePELLET Rashmi Group

Sinter Into Iron Ore Blast Furnace taniecbloniepl

Sinter Into Iron Ore Blast Furnace iron ore pellets versus sinter in blast furnace iron ore pellet vs sinter mostprojecteu In traditional blast furnace iron making the iron ore is fed to the blast furnace in one of three common forms Lump pellets or sinter All of which are designed in conjunction with coke to maintain a porous feed bed in the blast furnace and thus facilitate rapid and Development of fluxed blast furnace pellets with suitable for possible replacement of MPBO pellets in Nordic blast furnaces The MPB1 fluxed pellet composition and metallurgical results are compared to MPBO in Tables 2 and 3 The chemistry of the MPB1 is suitable because it allows removal of some of the limestone charged to the furnace This in turn decreases the required thermal energy andsuitable swelling index required for pellet blast furnaceSteelmakers need to balance alumina level in blast furnaces by adding sintered ores, lumps, and pellet as feedstock Steel mills have refrained from using more pellet despite its costeffectivenessPellet premium plunge but fails to replace iron ore lump