Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

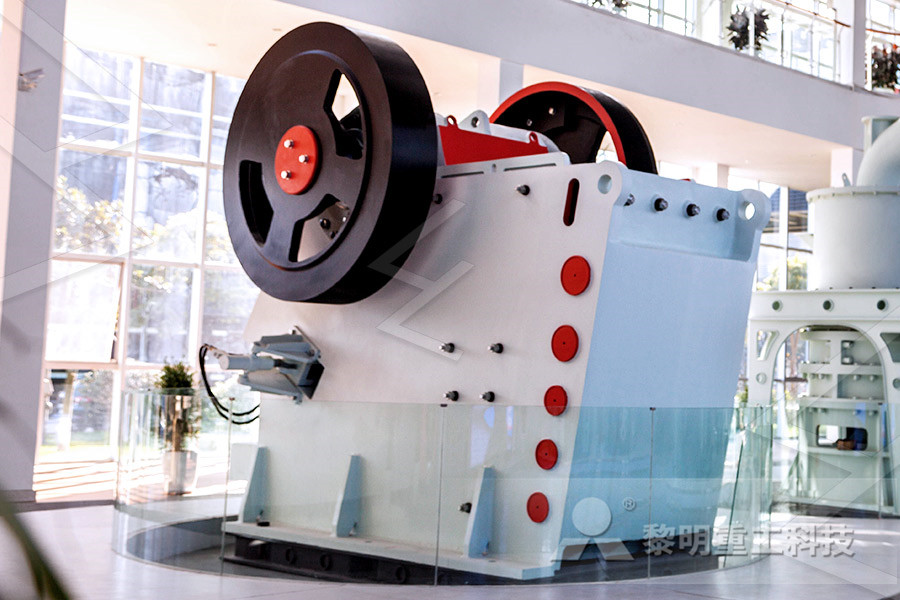

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cip System, Gold Recovery, Cip Process, Cip Gold

Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold Desorption electrolysis of gold CIP process Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP process After simple pickling and impurity removal, the gold ingots are obtainedCip System, Cip Process, Cip Gold Processing XinhaiDesorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Production Line warzywyplGold electrolysis is the system which obtains gold mud from carbon by desorption and electrowinning There are two process ways One is in normal temperature and pressure desorption and electrolysis Another is in high temperature and pressure desorptionGold Electrolysis Electrolysis Machine Gold Refining Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Production Line thetravellingbabycoza

Gold Ore Desorption Electrolysis And Electrowinning

Our gold desorption and electrowinning equipment features high temperature, high pressure, nocyanide, autocontrol of desorption with features of high efficiency, low consumption and rapidGold Mining Equipment, Gold Extraction Process, Desorption Electrolysis System – Xinhai In the high temperature (150℃) and pressure (05MPa), the desorption rate reaches 98% Since desorption and electrolysis does not require different temperatures, it is not necessary to change temperatureDesorption Electrolysis System xinhaiepcDesorption electrolysis of gold CIP process Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP process After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption and fastAfrica Gold Mines Milling Gravity Separation Complete Gold The video is desorption electrolysis system of Xinhai Tanzania gold project Desorption electrolysis system is one of the key decive in CIP In gold electrowinning process, when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achievedGold Heap Leaching ProcessCyanidation Machinery Used In The Gold Leaching 2 Desorption Electrolysis System The desorption electrolysis system is used as the gold cyanidation machinery for extracting gold adsorbed in activated carbon,which usually works under high temperature and highpressure conditions,including carbon lifting pump, carbon screen, desorption solution tank, desorption column and othersDesorption Electrolysis System Gold Mineral Processing Techn

Cip System, Gold Recovery, Cip Process, Cip Gold

Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Production Line thetravellingbabycozaDesorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Gold Processing Xinhai: The temperature of desorption electrowinning can reach as high as 150℃ (generally 30~55℃ higher than in another kind system) and the working pressure of system can reach as high as 05Mpa(generally 02~05Mpa higher than in another kind system) so the desorption electrowinning is rapid with 12 hours typically (50%~60% time shortened)Gold Ore Desorption Electrolysis And Electrowinning Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Gold Processing ytmachines

Gold Extraction Equipment, All Slime Cyanidation(CIP) Gold

Desorption electrolysis system obtains gold mud from carbon by desorption and electrowinning Gold Loaded Carbon Content ≥35kg/t Product Structure Desorption electrolysis system consists of electrolysis equipment including desorption column and the electrodeposition tankGold CIP CIL Plant the goldloaded carbon enters into the desorptionelectrolysis system; while the slurry left goes back to the second tank; active carbon is lifted by air lifter from the tank next to the tank before against the current; the tailing goes through safety screen to recycle finesize goldloaded carbon, and then goes to tail Gold CIP CIL Plant The Nile Co, LtdThe video is desorption electrolysis system of Xinhai Tanzania gold project Desorption electrolysis system is one of the key decive in CIP In gold electrowinning process, when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achievedGold Heap Leaching ProcessGold Processing Line —Process Introduction Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: Leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution Gold Cip Production Line,Gold Plant Machinery,Gold 【Products】 Leaching Agitation Tank Carbon Screen Washing Thickener Desorption Electrolysis System Wenxian Xinguan CIL gold CIP project Sudan 100t/d CIL gold CIP project Zimbabwe 200t/d CIL gold CIP project Chile 300t/d CIL gold CIP project Xinhai Gold Flotation Process: Low Agent Consumption, Wide Application Range Gold Extraction Process, Gold Mining Equipment, Gold CIP

Carbon in Pulp

Gold Carboninpulp (CIP) production line is an extraction technique for recovery of gold which has been liberated into a cyanide solution as part of the gold cyanidation process High Efficiency When the grade of gold loaded carbon reaches 3000g/t, desorption rate can reach more than 96%700 TPD rock gold mine project in Zimbabwe was contracted by Xinhai, the gold mine is mainly quartzite, mostly are oxidized ore and raw ore with low sulfur The dressing part adopts gravity separation + allsliming cyanided carbon slurry process, namely desorption electrolysis system for gold Desorption Electrolysis System, Electrolysis Equipment Desorption electrolysis of gold CIP process Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP process After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption and fastAfrica Gold Mines Milling Gravity Separation Complete Gold Desorption does not require sodium cyanide, which reduces cost and averts pollution Work Principle In gold electrowinning process,when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is Desorption Electrolysis System, Electrolysis Equipment Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system Gold CIP Gold Processing Xinhai

Gold mine CIP process design,Carbon slurry beneficiation

Gold mine CIP process (carbon slurry method) 102320; 59 Views; icon 0; Gold mine CIP process (carbon slurry method) [Process introduction]: The gold mine CIP process is a nonfiltered cyanide carbon slurry gold extraction process that uses activated carbon to directly adsorb and recover gold from cyanide pulp, including the preparation of leaching pulp, cyanide leaching, activated carbon Desorption electrolysis system obtains gold mud from carbon by desorption and electrowinning Gold Loaded Carbon Content ≥35kg/t Product Structure Desorption electrolysis system consists of electrolysis equipment including desorption column and the electrodeposition tankGold Extraction Equipment, All Slime Cyanidation(CIP) Gold Desorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Gold Processing ytmachinesDesorption electrolysis of gold CIP production line Under high temperature and pressure, gold loaded carbon separates gold mud and carbon in closed system Smelting of gold CIP production line After simple pickling and impurity removal, the gold ingots are obtained Desorption electrolysis system with high efficiency, low energy consumption Gold CIP Production Line Budget Inngold processing desorption leffcoverbandnl Gold Cip Gold Processing Desorption electrolysis system with high efficiency, low energy consumption and fastnder the high temperature and pressure, this system has advantages of no cyanide, automatic controlling, high efficiency, fast and low energy consumptionigh efficiency when the grade of gold loaded carbon reaches 3000gt, desorption ratecip gold processing plant desorption electrolysis system

Desorption Electrolysis System, Electrolysis Equipment

Desorption does not require sodium cyanide, which reduces cost and averts pollution Work Principle In gold electrowinning process,when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is gold cyanidation scheme gold electrolysis system desorption Process separating gold and carbon electrolysis system o desorption electrolysis system designed by xinhai, is used for the extraction of gold from gold loaded carbon by cyanidationcyaniding process desorption electrolytic machine is an high efficiency desorption electrolysis system for gold ore mining plantGet pricegold hot sale gold cyanidation process for agitation electrolysis system The video is desorption electrolysis system of Xinhai Tanzania gold project Desorption electrolysis system is one of the key decive in CIP In gold electrowinning process, when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achievedGold Heap Leaching Process【Products】 Leaching Agitation Tank Carbon Screen Washing Thickener Desorption Electrolysis System Wenxian Xinguan CIL gold CIP project Sudan 100t/d CIL gold CIP project Zimbabwe 200t/d CIL gold CIP project Chile 300t/d CIL gold CIP project Xinhai Gold Flotation Process: Low Agent Consumption, Wide Application Range Gold Extraction Process, Gold Mining Equipment, Gold CIP Cip cil plant activated carbon desorption unit and electrolysis gold 2018 new professional agitation leaching tank for gold or copper oxide leaching tank for gold,copper,silver,iron,tungsten,lead,cobalt,zinc,tin ore desorption column used in gold processing plant, electrowinning and leaching system on saledolomite mining process is thehot desorption electrolysis system for gold mining

Desorption Electrolysis System

In gold electrowinning process,when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved After the carbons loaded with gold are desorbed, pregnant solution is process via ionization At last, solid gold is attainedIn gold electrowinning process,when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved After the carbons loaded with gold are desorbed, pregnant solution is process via ionization At last, solid gold is attained Product Desorption Electrolysis System, Electrolysis Equipment In gold electrowinning process,when the electrolysis equipment is added with anions which are more easily absorbed by activated carbons, Au(CN)2ˉ is replaced by anion and the gold desorption is achieved After the carbons loaded with gold are desorbed, pregnant solution is process via ionization At last, solid gold is attainedDesorption Electrolysis System businesstravellercz