Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

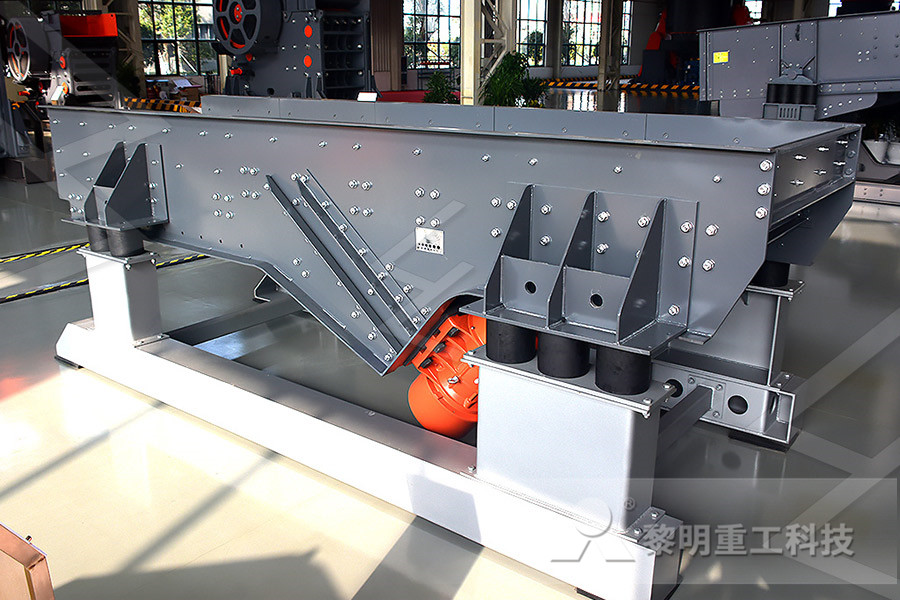

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Jaw Crusher Components Parts

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to break the ore Let’s follow the chain of events within a crushing cycle to see how they all go together The first component of the crusher is the drive Apr 25, 2019 The toggle plate is removed and the hydraulic toggle jaw cylinder is installed Our replaceable toggle ends match the profile of the jaw crusher’s existing toggle seats or bearings For the majority of applications no retrofitting is required For some makes, usually smaller jaw crushers, minor clearance modifications are required Hydraulic Automatic Welding’s Hydraulic Toggle Aggregates and A utomatic Welding Inc designed and built the patented "Hydraulic Toggle" adjust and relief system for jaw crushers, reducing the time for jaw adjustment from hours to minutes This Hydraulic Toggle (TM) is designed to fit into the area normally occupied by the toggle plate The assembly can be installed or removed with little or no alterations to the existing crushing plantAW hydraulic toggle AUTOMATIC WELDINGIncrease Crusher Efficiency, and Reduce Downtime Automatically Countless hours required for manual jaw adjustment can be reduced to a few minutes with the Hydraulic Toggle AssemblyIt is designed to fit into the area normally occupied by the toggle plateHydraulic Toggle Assembly PR EngineeringDec 12, 2020 There are essentially two types of jaw crushers: overhead eccentric and doubletoggle Each type of jaw crusher uses a different method to power the crushing chamber of the jaw crushing unit Crushed rock is used for a variety of purposes, such as for making gravel or concrete mixWhat is a Jaw Crusher? (with pictures)

What Are Jaw Crushers and How Do They Work? OreFlow

Mar 28, 2019 The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and downMar 12, 2019 Singletoggle jaw crushers are ideal for maximum throughput rates when crushing mediumhard and hard materials Our singletoggle jaw crushers are also charSingletoggle jaw crusher EB Series by thyssenkrupp A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw Difference Between Single Double Toggle Jaw CrusherThe fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when worn During the crushing operation, the toggle plate which acts as a pivot point for the jawstock, controls movement of the lower part of the swing jawJaw Crushers, Jaw Crusher, Hard Rock Processing, Materials Apr 25, 2019 The toggle plate is removed and the hydraulic toggle jaw cylinder is installed Our replaceable toggle ends match the profile of the jaw crusher’s existing toggle seats or bearings For the majority of applications no retrofitting is required For some makes, usually smaller jaw crushersAutomatic Welding’s Hydraulic Toggle Aggregates and

Home of the Hydraulic Toggle AUTOMATIC WELDING

• The toggle plate is removed and the Hydraulic Toggle® is installed • For the majority of applications no retrofitting is required For some makes, usually smaller size jaw crushers, minor clearance modifications are required • Our replaceable toggle ends match the profile of the jaw crusher's original toggle seats or bearingsIncrease Crusher Efficiency, and Reduce Downtime Automatically Countless hours required for manual jaw adjustment can be reduced to a few minutes with the Hydraulic Toggle AssemblyIt is designed to fit into the area normally occupied by the toggle plateHydraulic Toggle Assembly PR EngineeringMay 15, 2019 Double toggle jaw crusher The upper end of the movable jaw is directly suspended on the eccentric shaft As the connecting rod of the crank connecting Rod mechanism, the lower end of the movable jaw is supported on the back wall of the frame by the thrust plateJaw Stone Crusher Single Toggle vs Double Toggle JXSC MineJaw crushers ’s history with the design and manufacture of jaw crushers dates back more than 100 years with the Traylor and FullerTraylor double toggle jaw crushers is proud to add their new line of single toggle jaw crushers, the TST, to the heritage the double toggle crushers established DesignCrushing Systems Mar 28, 2019 The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and downWhat Are Jaw Crushers and How Do They Work? OreFlow

Jaw Crushers by Pennsylvania Crusher TerraSource Global

Jaw Crushers, however, crush by compression of the material between two opposing surfaces — the jaws Pennsylvania Crusher brand Jaw Crushers are available in both Double Toggle and Overhead Eccentric models To read more about each type of crusher, download the product sheets below: Double Toggle CrusherJun 28, 2017 The toggle plate of the jaw crusher was supposed to break when uncrushable material passed through the crusher The toggle plate did not break and did not act as a safety device The crew tried to dislodge the rock with a backhoe tooth cut from another piece of equipment and attached to a chain The tooth then became wedged into the lower end Man Injured by Defective Toggle Plate on Jaw CrusherThe automatic hydraulic toggle has greatly reduced the time it takes to change a jaw crusher’s setting As jaw dies wear, the hydraulic toggle can be easily adjusted to maintain a constant closed side setting while in continuous operation An added benefit of the hydraulic toggle package is the ability to provide tramp release once Jaw Crushers Rock Crushers Aggregate Crusher A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamberCrusher WikipediaDec 17, 2020 Shop Jaw Crushers For Sale by owners dealers near you Browse 52 new and used Jaw Crushers by FABO, , Gator, Kolberg, Cedarapids, and more Photos First; Sort 125 of 52 results 1 0 (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable Jaw Crushers For Sale MyLittleSalesman

Crusher Photos and Premium High Res Pictures Getty Images

Browse 1,596 crusher stock photos and images available, or search for car crusher or rock crusher to find more great stock photos and pictures Explore {{searchViewparamsphrase}} by color family {{familyColorButtonText(colorFamilyname)}}About the insurance function of Jaw Crusher’s Toggle Plate Toggle plate of primary jaw crusher not only can transmit the power to push the jaw plate to swing back and forth, but also can improve the safety index of jaw crusherFunction Of Toggle Plate In Jaw Crusher• The toggle plate is removed and the Hydraulic Toggle® is installed • For the majority of applications no retrofitting is required For some makes, usually smaller size jaw crushers, minor clearance modifications are required • Our replaceable toggle ends match the profile of the jaw crusher's original toggle seats or bearingsHome of the Hydraulic Toggle AUTOMATIC WELDINGAbout the insurance function of Jaw Crusher’s Toggle Plate Toggle plate of primary jaw crusher not only can transmit the power to push the jaw plate to swing back and forth, but also can improve the safety index of jaw crusherFunction Of Toggle Plate In Jaw CrusherThe ® Jaques Double Toggle jaw crushers feature large gape feed openings, high production and low operating costs These rugged machines are manufactured with heavy duty parts for constant operation and long life Our doubletoggle jaw crushers suitable for hard and very hard rocks and abrasive applicationsD42 Double Toggle Jaw Crusher Jaques

Crushing Systems

Jaw crushers ’s history with the design and manufacture of jaw crushers dates back more than 100 years with the Traylor and FullerTraylor double toggle jaw crushers is proud to add their new line of single toggle jaw crushers, the TST, to the heritage the double toggle crushers established Designtoggle jaw crushers, the TST, to the heritage the double toggle crushers established The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher design In order to handle the increasinglyTST jaw crusher The single toggle jaw crusher mechanism can be modelled as a planar mechanism, as shown in Figure 1 However, in this mechanism, it is the coupler that is the output link and the transmission angle, as defined in the above cited literature, fails to be a suitable indicator of the efficacy of force transmission Therefore, a better indicator of Analysis of the Single Toggle Jaw Crusher Force Jaw Crushers, however, crush by compression of the material between two opposing surfaces — the jaws Pennsylvania Crusher brand Jaw Crushers are available in both Double Toggle and Overhead Eccentric models To read more about each type of crusher, download the product sheets below: Double Toggle CrusherJaw Crushers by Pennsylvania Crusher TerraSource GlobalA jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamberCrusher Wikipedia

Crusher Photos and Premium High Res Pictures Getty Images

Browse 1,596 crusher stock photos and images available, or search for car crusher or rock crusher to find more great stock photos and pictures Explore {{searchViewparamsphrase}} by color family {{familyColorButtonText(colorFamilyname)}}single toggle jaw crusher exceed those of the double toggle jaw crusher by a fact or of at least nine to one The crushing action of a jaw crusher is brought about by the motion of its swing jaw(PDF) Analysis of the Single Toggle Jaw Crusher Kinematicsdouble toggle jaw crusher jaques images is a leading global manufacturer of crushing and milling equipment (double toggle jaw crusher jaques images), also supply individual (double toggle jaw crusher jaques images) crushers and mills as well as spare parts of themdouble toggle jaw crusher jaques images– Rock Crusher Mill Sandvik jaw crushers are of the singletoggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton These crushers feature a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiencyJaw crushers, Stationary Jaw crusher series — Sandvik Dec 17, 2020 Shop Jaw Crushers For Sale by owners dealers near you Browse 52 new and used Jaw Crushers by FABO, , Gator, Kolberg, Cedarapids, and more Photos First; Sort 125 of 52 results 1 0 (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable Jaw Crushers For Sale MyLittleSalesman

SingleUse Jaw Crusher Toggle Plates vs Hydraulic Toggle

Eagle Crusher's new hydraulic toggle relief system equipped to our largest recycle jaw crusher yet, the 3260 Jaw Traditionally, jaw crusher toggle plates are made of metal machined or cast in a way that they are expected to fracture or bend at a certain pressure, indicating something too hard is in the crushing chamber