Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

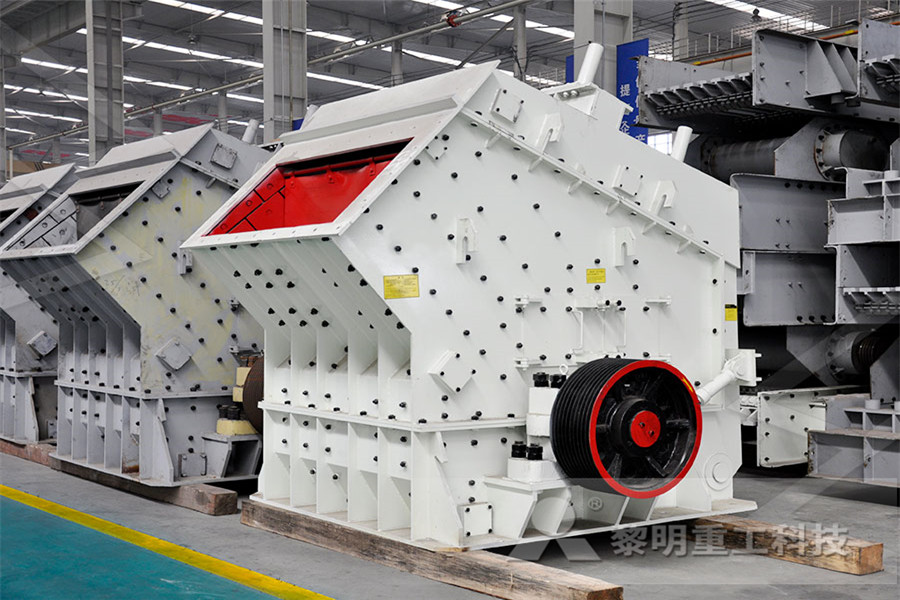

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

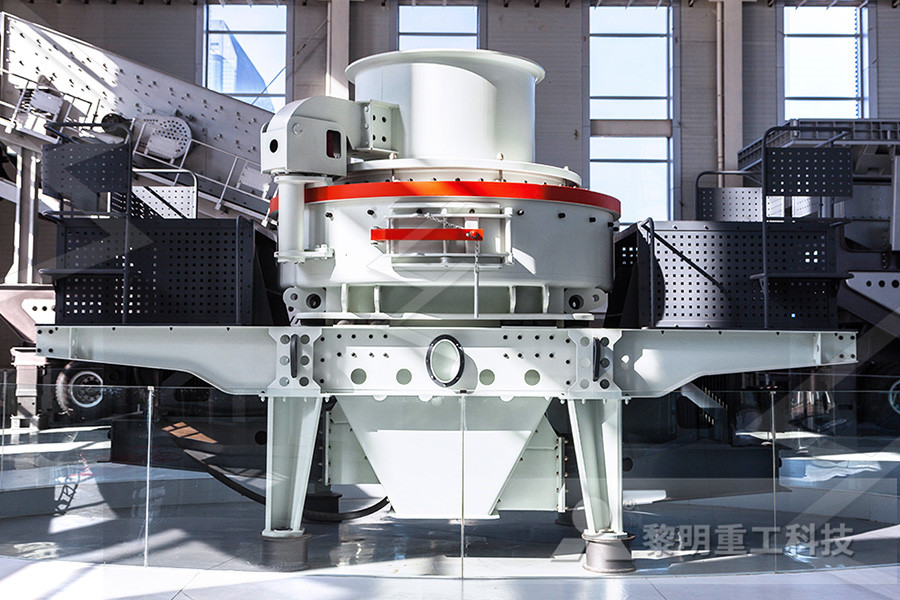

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Froth Flotation Process Detailed Explanation With

Apr 06, 2020 Flotation is the process of separation of beneficial minerals from a mixture by creating froth on which minerals separate out This method of froth floatation is a method of mineral processing in which different minerals are separated selectivelyFlotation processes are based on the different surface wettability properties of materials (Wang et al, 2015) In principle, flotation works very similarly to a sink and float process, where the density characteristics of the materials, with respect to that of the medium where they are placed are at the base of the separationFlotation Process an overview ScienceDirect TopicsThe flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability The China flotation separating production line consists of the following parts: jaw Flotation separation processChina flotation separating The flotation separation process is one of the most important processes, widely used in mineral separation According to statistics, more than 90% of nonferrous metal is separated with a flotation separation process Flotation Separation Process Advantage 1 Our company's flotation production line is not only efficient and energysaving, but Flotation Separation Process Mining MachineryFlotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by waterFlotation ore dressing Britannica

How Dissolved Air flotation Systems for Water Treatment

Feb 13, 2018 The flotation process in wastewater treatment plays a pivotal role in meeting environmental discharge compliances and regulations Dissolved Air Flotation Systems for Water Treatments Dissolved air flotation is a process utilized across a myriad of industries In fact, water or wastewater treatment creates mineral and organic sludges from Flotation separation Flotation is the most widely used method for the concentration of finegrained minerals It takes advantage of the different physicochemical surface properties of minerals—in particular, their wettability, which can be a natural property Mineral processing Concentration BritannicaFlotation separation process consists of those machines such as vibrating feeder, chute feeder, jaw crusher, vibrating screen, ball mill, spiral classifier, pendulum feeder, high frequency screen, mixer, flotation cell, concentrator, dryer and so onFlotation Separation Process MachineryThe flotation separation process also known as the flotation separating production line realizes the mineral particle separation based on the working principle of different physical and chemical properties of the minerals leading to different floatability The China flotation separating production line consists of the following parts: jaw Flotation separation processChina flotation separating The flotation separation process is one of the most important processes, widely used in mineral separation According to statistics, more than 90% of nonferrous metal is separated with a flotation separation process Flotation Separation Process Advantage 1 Our company's flotation production line is not only efficient and energysaving, but Flotation Separation Process Mining Machinery

Flotation Device, Froth Flotation, Flotation System

Introduction: Flotation separation process is one of the most widely mineral processing method used in the production It uses the difference of physical and chemical properties in mineral surface, and rely on air bubbles buoyancy in the pulp to realize mineral separation processDec 17, 2020 Froth flotation is a process using air bubbles to separate materials based on their relative affinity to water Bubbles carry reagent and hydrophobic materials to the top of a tank where they can be removed Froth flotation has been used for more than a century in mining operations to separate valuable materials from excavated oresWhat is Froth Flotation?Feb 13, 2018 Dissolved air flotation (DAF) is a water treatment process designed to remove oils, solids, and greases In fact, the process helps clarify wastewaters – and other waters – by eliminating different types of suspended matter The DAF process dissolves air in the water under pressure – then releases it at atmospheric pressureHow Dissolved Air flotation Systems for Water Treatment Flotation separation process is one of the most important processes in mineral separation, wide very extensive application According to statistics, more than 90% nonferrous metal is separated with flotation separation processFlotation Separation Process MachineryThe flotation separation process is one of the most important processes, widely used in mineral separation According to statistics, more than 90% of nonferrous metal is separated with a flotation separation process Flotation Separation Process Advantage 1 Our company's flotation production line is not only efficient and energysaving, but Flotation Separation Process Mining Machinery

Foams in mineral flotation and separation processes

Foam flotation is a process used worldwide to separate metallic and nonmetallic minerals from extracted ore It is probably the single most important operation used in the mining industry in the world today In the United States, for example, over onethird of the mineral concentrates produced are obtained using flotation [I]Flotation separation process is one of the most important processes in ore beneficiation, so its use is extensive It is widely used in concentrates selection of copper ore, nickel ore, iron ore, gold ore, limestone and other metal and nonmetallic ore, with advantages of high efficiency, low energy consumption, high processing capacity, and reasonable economy, etcFlotation Separation ProcessFote MachineryDec 17, 2020 Froth flotation is a process using air bubbles to separate materials based on their relative affinity to water Bubbles carry reagent and hydrophobic materials to the top of a tank where they can be removed Froth flotation has been used for more than a century in mining operations to separate valuable materials from excavated oresWhat is Froth Flotation?May 05, 2010 Follow us at: https://plusgoogle/+tutorvista/Check us out at chemistrytutorvista/inorganicchemistry/metallurgyhtmlFroth Floatation ProcessFroth Floatation Process YouTubeFlotation Process an overview ScienceDirect Topics In principle, flotation works very similarly to a sink and float process, where the density characteristics of the materials, with respect to that of the medium where they are placed are at the base of the separationFlotation Separation Process Brief Description

floatation separation process masazemisacz

Flotation ore dressing BritannicaFlotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic orIrrespective of the project, the development of the optimum flotation process is reliant on three key factors: • understanding of the geology and associate mineralogical variations that impact on Separation may be a simple bulk float (iepyritic gold ores, some copper ore with negligible pyrite) or as is the case for polymetallic ores, a INTERPRETATION OF FLOTATION DATA FOR THE DESIGN OF Flotation testwork is carried out using Agitair and Denver cells and is performed by trained, experienced metallurgical technicians to ensure consistent, reliable results Today froth flotation remains the separation process of choice for most sulphide deposits (eg Pyrite FeS 2), and an increasing number of other mineralsMineral Sands Process Development5 Types of Phosphate Froth Flotation Process Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation difficulty and flotation types variesMineral Flotation, Flotation Separation, Forth Flotation Grading desliming is the most commonly used method, such as separating a certain size of sludge with a hydrocyclone before flotation, or discarding it or treating the sludge and coarse sand separately, that is, the socalled "silt separation "For some easyfloating sludge, a small amount of foaming agent can also be added before flotation to Fine particle flotation process,separating sludge with a

Flotation SlideShare

Aug 14, 2017 UNIT OPERATION OF FLOTATION • Separation: separation is then intended to generate and introduce air bubbles into the process vessel for contacting them with particulate species Particles attached to the air bubbles are in most applications removed from the process vessel as froth accordingly the unit operation of flotation is referred to as