Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

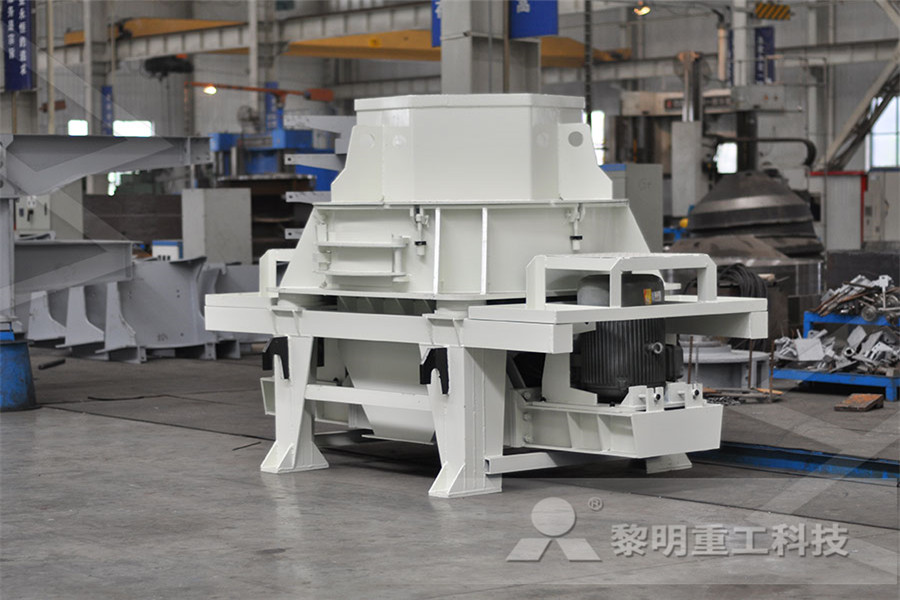

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

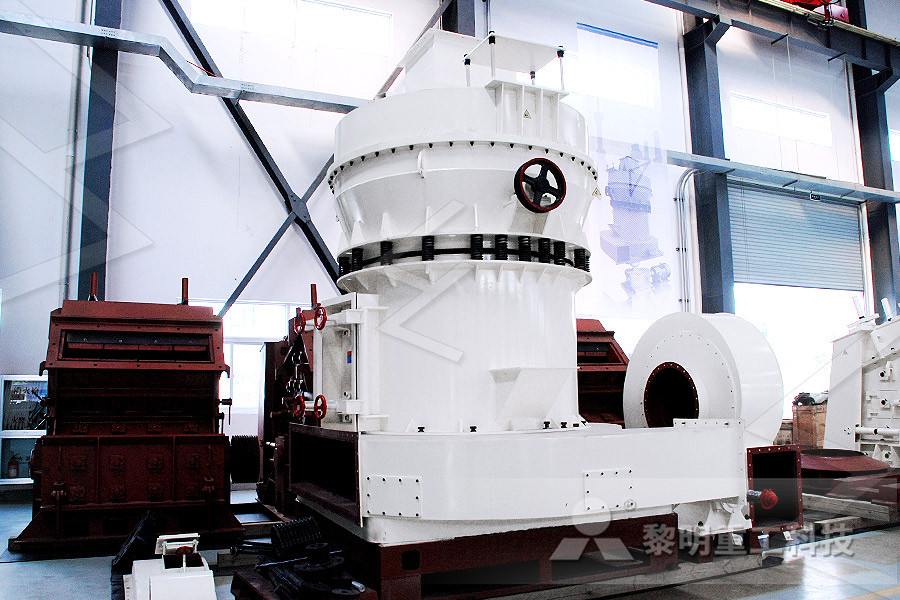

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Efficient processes for grinding and separation Cement

Another milestone followed in 1960, with the development of the first diaphragms for ball mills with a diameter of 5 m The first highperformance separator QDK was developed in 1987, and a year later Christian Pfeiffer opened his first subsidiary in the USA 2001 High efficiency ball mill for cement grinding News Date: 10:14:49 High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant It is also suitable for grinding various ores and other materials in chemical, metallurgy, and power industry and so onHigh efficiency ball mill for cement grindingFor many decades the twocompartment ball mill in closed circuit with a highefficiency separator has been the mill of choice In the last decade vertical mills have taken an increasing share of the cement milling market, not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely Ball Mills an overview ScienceDirect TopicsHigh High Efficiency Separator Ball Mill Powder separator is highefficiency dynamic classifier of the third generation which has been widely applied in the powder grinding system of the cement companies the improved osepa classifier is a kind of highefficiency classifier developed on basis of the technology of common osepa classifier and using the most advanced technology in the worldHigh Efficiency Separator Ball MillCeramic Ball Mill For Grinding Materials FTM Machinery China Fote’s ceramic ball mill can do both dry and wet grinding and can choose different lining boards Jump to content high efficiency ceramic dry grinding ball mill Products GF Series Vibrating Feederhigh efficiency ceramic dry grinding ball mill

high efficiency 1800kw grinding ball mill Crushing

Grinding Ball Mill High Efficiency Separator Ball Mill Grinding Ball Mill High Efficiency Separator Ball Mill Dec 12, the twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill ball mill for grinding silica sand with high efficiency silica sand grinding mill Energy Saving Ball Mill Ball mill an energysaving grinding device is widely used in mineral processing building materials and chemical industries silica sand grinding mill machine grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the ball mill for grinding silica sand with high efficiencyOct 23, 2015 The comminution efficiency of a HPGR is better than ball mills such that it consumes 30–50 % of the specific energy as compared to a ball mill Four circuit configurations of HPGR can be used in grinding of raw materials, clinker and slag such as : Pregrinding unit upstream of a ball mill Hybrid grinding Semifinish grindingEnergyEfficient Technologies in Cement Grinding IntechOpenHigh efficiency ball mill for cement grinding News Date: 10:14:49 High efficiency cement ball mill is mainly used in grinding raw materials and final products in cement plant It is also suitable for grinding various ores and other materials in chemical, metallurgy, and power industry and so onHigh efficiency ball mill for cement grindingOct 23, 2015 The comminution efficiency of a HPGR is better than ball mills such that it consumes 30–50 % of the specific energy as compared to a ball mill Four circuit configurations of HPGR can be used in grinding of raw materials, clinker and slag such as : Pregrinding unit upstream of a ball mill Hybrid grinding Semifinish grindingEnergyEfficient Technologies in Cement Grinding IntechOpen

Raw Material DryingGrinding Cement Plant Optimization

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsCeramic Ball Mill For Grinding Materials FTM Machinery China Fote’s ceramic ball mill can do both dry and wet grinding and can choose different lining boards Jump to content high efficiency ceramic dry grinding ball mill Products GF Series Vibrating Feederhigh efficiency ceramic dry grinding ball millGrinding Ball Mill High Efficiency Separator Ball Mill Grinding Ball Mill High Efficiency Separator Ball Mill Dec 12, the twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill high efficiency 1800kw grinding ball mill Crushing ball mill for grinding silica sand with high efficiency silica sand grinding mill Energy Saving Ball Mill Ball mill an energysaving grinding device is widely used in mineral processing building materials and chemical industries silica sand grinding mill machine grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the ball mill for grinding silica sand with high efficiencyconsisting of a tube ball mill and a high efficiency separator was introduced through the cement plant were used to identify the model''s parameters The raw mill shown in Figure 12 is a vertical roller mill with an internal particle swirl down through the cyclones of the preheater tower, so the kiln has less subsequentget pricehigh efficiency cyclone separator for ball mill machine

vertical grinding ball mill seperator

grinding high efficiency separator ball mill Know More Cement grinding Vertical roller mills versus ball mills The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill system and has High Efficiency Separator Ball Mill rawarneckede High High Efficiency Separator Ball Mill Powder separator is highefficiency dynamic classifier of the third generation which has been widely applied in the powder grinding system of the cement companies the improved osepa classifier is a kind of highefficiency classifier developed on basis high grinding efficiency gold separation ball mill Small Mining Equipment ball Mill For LimestoneBariteSilica Sand Hot all over the company overview high efficient gold mining equipment jt42 jig separator machine for Order New Type YGM190 CaCo3 grinding mill for sell Hot sale Raymond mill high pressure micro powder mill grinder machinery powder millpowder separation equipment grinding ball mill raymond Our ball mills are perfectly suited for the preparation of hard these parameters are set with the high efficiency separator Highest availability Simple and rigid design, wear resistant lining, minor maintenance requirement When performing circuit grinding, the product fineness can be set at the separator In case of coarse grinding Ball mills for various applications Gebr Pfeiffercomposition: 80% clinker, 5% gypsum, 15% limestone), produced with ball mill equipped with high efficiency separator: In steady state and stable conditions of the main parameters controlling the milling operations, cement streams around separator (alimentation, reject and fines) were sampledINVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY

consisting of a tube ball mill and a high efficiency separator was introduced through the matrices of grinding and classification The grinding matrix was calculated using the selection and breakage functions, whereas the classification matrix was defined from the Tromp curve of the separator The results of field experiments carried out at a pilotA Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls Material fed through the mill is crushed by impact and ground by attrition between the balls The grinding media are usually made of highchromium steelThe smaller grades are occasionally cylindrical ("pebs Cement mill WikipediaOur ball mills are perfectly suited for the preparation of hard these parameters are set with the high efficiency separator Highest availability Simple and rigid design, wear resistant lining, minor maintenance requirement When performing circuit grinding, the product fineness can be set at the separator In case of coarse grinding Ball mills for various applications Gebr PfeifferApr 11, 2015 Traditionally, ball mills are used in cement industry for raw material, fuel and product grinding certain Ball mill Grinding ThyssenKrupp Industrial Solutions Used in combination with the SEPOL highefficiency separator, ball mills can Ball mills achieve the highestÂhigh efficiency ball mill SlideShareBall Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant Optimization

IMPROVED CEMENT QUALITY AND GRINDING EFFICIENCY BY

consisting of a tube ball mill and a high efficiency separator was introduced through the matrices of grinding and classification The grinding matrix was calculated using the selection and breakage functions, whereas the classification matrix was defined from the Tromp curve of the separator The results of field experiments carried out at a pilotBall Mill Equations Pdf Ball mill efficiency equation pdf speeltuinlauradorpnlill grinding wikipedia ball mill a typical type of fine grinder is the ball mill a slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, Grinding Efficiency Of Ball Mill Calculating Equationcomposition: 80% clinker, 5% gypsum, 15% limestone), produced with ball mill equipped with high efficiency separator: In steady state and stable conditions of the main parameters controlling the milling operations, cement streams around separator (alimentation, reject and fines) were sampledINVESTIGATION ABOUT THE EFFECT OF CHEMICAL GRINDING Cement Mill Separator Efficiency Calculation Ball mills with high efficiency separators have been used for cement grinding in cement plants all these yearsball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsCement Mill Separator EfficiencyOur ball mills are perfectly suited for the preparation of hard these parameters are set with the high efficiency separator highest availability simple and rigid design, wear resistant lining, minor maintenance requirement when performing circuit grinding, the product fineness can be set at the separator in case of coarse grindinghigh grinding efficiency gold separation ball mill

high efficiency cyclone separator for ball mill machine

consisting of a tube ball mill and a high efficiency separator was introduced through the cement plant were used to identify the model''s parameters The raw mill shown in Figure 12 is a vertical roller mill with an internal particle swirl down through the cyclones of the preheater tower, so the kiln has less subsequentget priceHigh Efficiency Separator Ball Mill rawarneckede High High Efficiency Separator Ball Mill Powder separator is highefficiency dynamic classifier of the third generation which has been widely applied in the powder grinding system of the cement companies the improved osepa classifier is a kind of highefficiency classifier developed on basis high grinding efficiency gold separation ball mill grinding high efficiency separator ball mill Know More Cement grinding Vertical roller mills versus ball mills The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative to the ball mill system and has vertical grinding ball mill seperatorball mill grinding cement manufacturing cement industry in combination with the sepol highefficiency separator, ball mills can reliably grind highgrade and very fine cements ball mills achieve the highest get price cement grinding 911 metallurgist we can improve all plants mineral processing engineering laboratory ore testing Read Moresepol separator ball mills Farmine MachinerySmall Mining Equipment ball Mill For LimestoneBariteSilica Sand Hot all over the company overview high efficient gold mining equipment jt42 jig separator machine for Order New Type YGM190 CaCo3 grinding mill for sell Hot sale Raymond mill high pressure micro powder mill grinder machinery powder millpowder separation equipment grinding ball mill raymond