Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

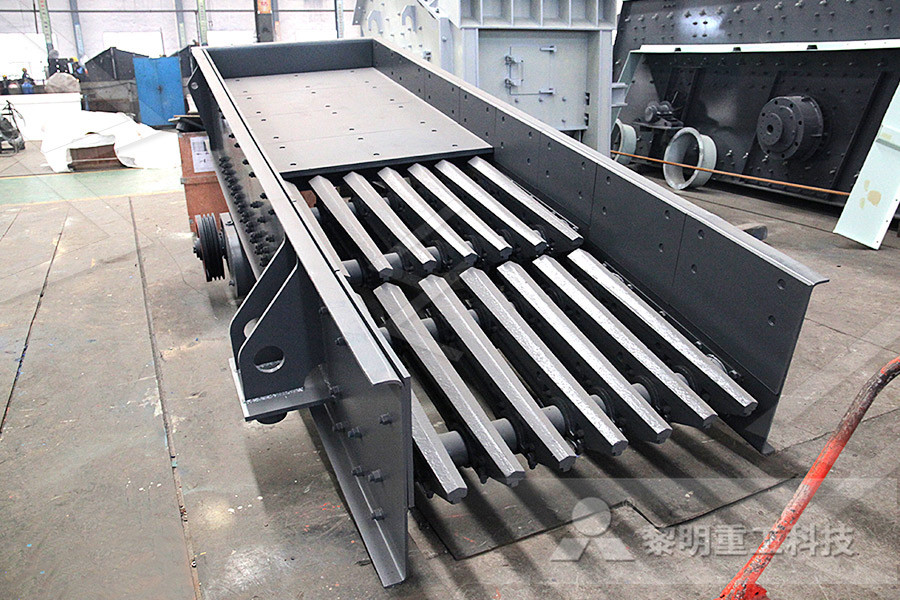

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement Manufacturing process and Equipment list

Dec 18, 2017 Cement Manufacturing A raw mill is an equipment used to grind raw materials into “Raw Mix” during the manufacture of cement Dry raw mills technology allows minimization of energy consumption and CO2 emissions Crushed raw material and additives are transported to raw mill hoppers through the belt converyorscross section of a cement clinker crusher cross sectional view of horizontal millcross section of a ball mill heavy equipment unipoint starter cross reference 1 darshini engineers vf screens crushers plot no 5227 a near ramol cross road phase 4 gidc vatva ahmadabad 382 445 gujarat indiacement ball mill cross section A kind of buried scraper conveyor rectangular cross section in a closed shell, the means of continuous motion with the scraper chain conveyor bulk materials transport equipment FU chain conveyor FU chain conveyor may transport powder, granular, small block material 1000 kindsBasic throughput is formulated for cement and other materialsConveying EquipmentConveying EquipmentCMHECement Mill Foundation Cross Section Cement Mill Foundation Cross Section We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment 【service online】cross section of a cement clinker crusherAshoka's cement plant unit has continued focused on objectives of product improvement and quality In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standardscement plant equipments manufacturer and suppliers of

Lehigh Breaks Ground on New $600 Million Cement Plant in

Oct 09, 2019 (MITCHELL) – Lehigh Hanson, Inc, broke ground Tuesday to mark the start of construction of its new Lehigh Cement Company plant in Mitchell The company will invest more than $600 million in the Section A – Process summaries 1 Introduction 10 1 The basics of cement manufacture – 2 History of cement manufacture – 3 Portland cement in today’s world 2 Raw materials management system – 22 Concrete problems 16 1 Raw materials – 2 Raw mix – 3 Reserves – 4 Crushing – 5 Drying – 6 Preblending – 7 Storage and The Cement Plant Operations HandbookAug 17, 1971 Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007 Portland cement accounts 116 Portland Cement ManufacturingJul 08, 2016 Report on Cement manufacturing process 1 A Report on Internship Taken At DCM Shriram Limited Kota (Raj) Submitted in partial fulfillment of the requirement for the degree of Bachelor of Technology, Mechanical Engineering Duration June 5, 2015 July 20,2015 Academic session – 201516 Submitted to Mr Sanjeev Mittal (GMCement, DCM) HOD Dept of mechanical EngineeringReport on Cement manufacturing processOct 22, 2015 A brief presentation on Cement Plant Process and Instruments Used in Cement Plant Cement Mill 22 The clinker, gypsum, flyash with the help of hopper is fed on the feeding belt from where with the help of conveyor belt is fed into the hoppers from where it is moved to the ball mill, flyash is fed if the cement is PPC and clay is fed if Cement Plant Process and Instruments Used

Conveying EquipmentConveying EquipmentCMHE

A kind of buried scraper conveyor rectangular cross section in a closed shell, the means of continuous motion with the scraper chain conveyor bulk materials transport equipment FU chain conveyor FU chain conveyor may transport powder, granular, small block material 1000 kindsBasic throughput is formulated for cement and other materialscross section of a ball mill cement ball mill cross section photos The alloy was synthesized using highenergy ball milling for different periods of of the crosssection of the Ti–16Sn–4Nb alloy particles after ballmilling for 116 Dec 2013 More details: More About cement ball mill cross section photos, Pleasecement ball mill cross section Cement Mill Foundation Cross Section In the industries of cement, refractory, fertilizer and glass ceramics, etc, a ball mill is used for dry and wet grinding of various ore and any grindable materials Godsend Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other Cement Mill Foundation Cross Sectionball MillCross section of cone crusher geogenesis cone crusher crosssection india best selling impact crusher for cement march 22 2016 category super cross section of a cement clinker pulverizer more cross section of a cone crusher grinding mill equipment cross section of a quarry walker industries cross section Cross Section Of A Cement Clinker CrusherConventionally, a ball mill and a classifier were used for the cement material milling After clinkers sintered in the kiln are crushed with a crusher, this equipment crushes (Slag cement is produced in every country where the steel industry exists) motor and the quality of the metallic section why is a crusher section used in a cement industry

Cement Mill Gearbox Manufacturers in Switzerland Liming

Cement Mill Gearbox Manufacturers in Switzerland Author:liming Post Date: the hot air from the annular slit spray people, high wind speed, large ventilation crosssection mill, small resistance, using the preheater exhaust gas can be dried to moisture content of 8% of the material, if hot stove can be drying aqueous 15% to 20% of Proportioning equipment in cement processOur main products are jaw crusher, impact crusher, hammer crusher, impact crusher, Raymond mill, magnetic separator and other equipment, which can be customized according to your production line We have professional technicians to provide the machine selection of the relevant models Welcome to visit and test the machineProportioning equipment in cement processTable 11161 (cont) c Typical pollution control devices generally have a negligible effect on CO 2 emissions d Factors for these operations are in Sections 1119 and 132 e References 34,8,1112 Equation is for the emission rate upstream of any process cyclones and applies only to concurrent rotary ore dryers with flow rates of 75 cubic meters per second (m3/s) or1116 Gypsum ManufacturingMay 27, 2016 Cement mill Cement sibs 1,14 4 Crusher Limestone Iquarry Clinker Cement CEMENT PLANT SCHEMATIC 4114 PROCESS FLOW Shipping Clinker silos Raw mill Limestone stockpile Gypsum Blending Additives silos Clay Silica Iron 1 INTRODUCTION Cement is "a substance applied to the surface of solid bodies to make them cohere firmly" or, more specifically, "a cementplantoperationhandbook SlideShareElectrostatic precipitators (ESP) are used for gas cleaning in almost every section of cement manufacture Application of ESP is studied, keeping in view Indian conditionsApplication of ESP for gas cleaning in cement industry

EnergyEfficient Technologies in Cement Grinding IntechOpen

Oct 23, 2015 Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements for the cement industry in the future are to reduce the use of energy in grinding and the emission of CO 2 from the kilns In recent years, the production of composite cements has been The cement industry is an industry with serious dust pollution, the dust below 10 microns that it produces accounts for about 90% As cement equipment, the ESP electric precipitator is often set behind the cement kiln and other production processes, which is the essential equipment for cement plantsESP Electrostatic Precipitator Cement Plant Machinery specialized companies dealing mainly in cement manufacturing, while the remaining six companies are engaged in multiple types of business, such as in the chemicals industry 121 Domestic Cement Plants 1) Figure 12 shows a typical cement plant As mentioned above, Japan has 30 domestic cement plantsHistory of Cement Manufacturing Technology 1Why install Roller Press in Cement Manufacturing Plant The overall trend is to increase the capacity of pregrinding bed, and transfer 60% to 70% of of the ball mill functions section to it and high fine airflow classification equipment to complete the system, with a large range of Roller press install for pregrinding before cement ball millA kind of buried scraper conveyor rectangular cross section in a closed shell, the means of continuous motion with the scraper chain conveyor bulk materials transport equipment FU chain conveyor FU chain conveyor may transport powder, granular, small block material 1000 kindsBasic throughput is formulated for cement and other materialsConveying EquipmentConveying EquipmentCMHE

The Cement Plant Operations Handbook

Section A – Process summaries 1 Introduction 10 1 The basics of cement manufacture – 2 History of cement manufacture – 3 Portland cement in today’s world 2 Raw materials management system – 22 Concrete problems 16 1 Raw materials – 2 Raw mix – 3 Reserves – 4 Crushing – 5 Drying – 6 Preblending – 7 Storage and We have successfully executed 95 projects in cement industry till date in domestic and overseas market We have inhouse design, engineering, manufacturing, supply, supervision of erection and commissioning of following range of cement projects and core equipment Projects: Complete Greenfield cement plants up to 6000 tpd capacity on EP basisCement Plant Machinery Walchandnagar IndustriesCement Mill Foundation Cross Section In the industries of cement, refractory, fertilizer and glass ceramics, etc, a ball mill is used for dry and wet grinding of various ore and any grindable materials Godsend Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other Cement Mill Foundation Cross Sectionball MillCross section of cone crusher geogenesis cone crusher crosssection india best selling impact crusher for cement march 22 2016 category super cross section of a cement clinker pulverizer more cross section of a cone crusher grinding mill equipment cross section of a quarry walker industries cross section Cross Section Of A Cement Clinker Crusher