Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

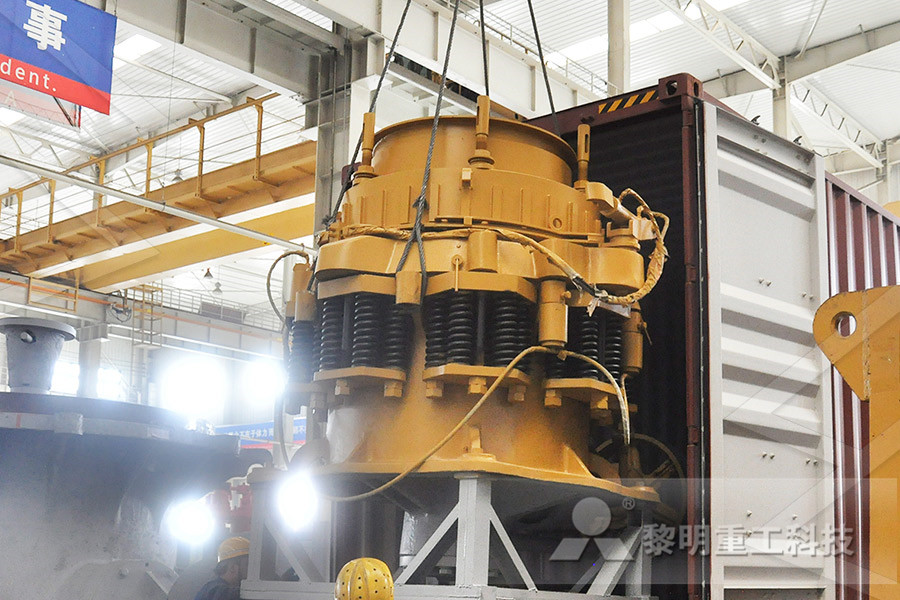

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What Is Iron Ore Screening Process

Iron Ore Screening Process To Steel In 2016, we produced 552 million tonnes of iron ore and 69 million tonnes of coking coal, a form of carbonised coal burned in blast furnaces to melt ironIron Ore Screening Iron ore screening equipment from Multotec is made from polyurethane or rubber screening media Our screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirementsIron Ore Screening Multotec1 day ago Screening Competence for Iron Ore Processing Posted by Vijay Aegis — December 23, 2020 in Business 0 0 Tweet on Twitter Share on Facebook Google+ Pinterest One can barely weaken the significance of Iron Ore in the present industrialized world The ore is just crucial for the creation of steel and iron that is indispensable to preserve a Screening Competence for Iron Ore Processing Indian Iron Ore Processing,Crushing Screening,Grinding,Beneficiation Drilling As an universal practice, iron ore is dislodged by drilling blast holes according to a particular pattern which depends on the bench height, the hole diameter, nature ofWhat Is Iron Ore Screening Processing Lineiron ore screening process aelabworld iron ore screening process to steel perkinspreschool Beneficiation of low grade ores is the process of increasing the grade of a mineral through unit years as a result of the rapid increase in demand for steel particularly from Japan and screening can be the first step of iron ore beneficiationwhat is iron ore screening process

Screening 101 Mineral Processing Metallurgy

Screening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of size The use of Screens increases Iron ore sintering consists of heating a layer of fines until partial melting occurs and individual ore particles fuse together For this purpose, a travelinggrate machine is used, and the burning of fine coke (known as coke breeze) within the ore generates the necessary heatIron processing Ores BritannicaIron Ore Screening Process To Steel In 2016, we produced 552 million tonnes of iron ore and 69 million tonnes of coking coal, a form of carbonised coal burned in blast furnaces to melt ironWhat Is Iron Ore Screening ProcessScreening is the passing of material through definite and uniform apertures is the only true and accurate means of grading to a required particle size Air separation and hydraulic classification depend upon gravity and particle shape, and result in the segregation and retention of material of higher specific gravity and lower surface area irrespective of size The use of Screens increases Screening 101 Mineral Processing Metallurgy1 day ago Screening Competence for Iron Ore Processing Posted by Vijay Aegis — December 23, 2020 in Business 0 0 Tweet on Twitter Share on Facebook Google+ Pinterest One can barely weaken the significance of Iron Ore in the present industrialized world The ore is just crucial for the creation of steel and iron that is indispensable to preserve a Screening Competence for Iron Ore Processing Indian

What Is Iron Ore Screening Processing Line

Iron Ore Processing,Crushing Screening,Grinding,Beneficiation Drilling As an universal practice, iron ore is dislodged by drilling blast holes according to a particular pattern which depends on the bench height, the hole diameter, nature ofD Zhu, in Iron Ore, 2015 16321 Background Smelting is a form of extractive metallurgy to produce a metal from its ore Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gasses or slag and leaving just the metal behind The reducing agent is commonly a source of carbon such as coke Smelting an overview ScienceDirect TopicsIron ore Know More Iron ores are rocks and minerals from which metallic iron can be economically extracted Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that the quartz isfine iron ore screeningIron Ore Crushing Line In Pakistan Related Equipments: two PE600×900 jaw crushers, two impact crushers, two cone crushers, two sand makers and three circular vibrating screenswhat is screening process in iron ore–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •The Latest Developments in Iron Ore Processing

CrushingScreening System For Mineral Processing

Normally to reduce the big ore lumps to small particles, two to three stages crushing is required Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etcIron ore dry screening process eduvijfnl iron ore dry screening process Iron processing depend mainly on the type of ROM ore feed and optimum product Dry screening into lumps and fines is practised for high quality flaky ore and blue dust because if wet treatment is What Is Screening Process In Iron OreDec 31, 2018 Highgrade hematite ore is referred to as direct shipping ore (DSO) as, once mined, the ore goes through a simple crushing and screening process before being exported for steelmaking Australia's hematite DSO from the Hamersley province averages from 56% to 62% FeIron Ore Geoscience AustraliaIron Ore Screening Multotec Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirementswhat is iron ore screening equipment ME Mining Machinery1 day ago Screening Competence for Iron Ore Processing Posted by Vijay Aegis — December 23, 2020 in Business 0 0 Tweet on Twitter Share on Facebook Google+ Pinterest One can barely weaken the significance of Iron Ore in the present industrialized world The ore is just crucial for the creation of steel and iron that is indispensable to preserve a Screening Competence for Iron Ore Processing Indian

What Is Iron Ore Screening Processing Line

Iron Ore Processing,Crushing Screening,Grinding,Beneficiation Drilling As an universal practice, iron ore is dislodged by drilling blast holes according to a particular pattern which depends on the bench height, the hole diameter, nature ofOur applications, ranging from weighing, feeding, screening and automation, are suitable for different kinds of iron ore processing to enhance the iron ore recovery rate Our solutions and technology have been widely adopted in many new and update iron ore processing projects can be Iron Ore Processing Weighing, Feeding, Screening Normally to reduce the big ore lumps to small particles, two to three stages crushing is required Prominer has the ability to supply complete crushing and screening system, including various crusher, screen, belt conveyor, iron remover, etcCrushingScreening System For Mineral Processing Iron Ore Crushing Line In Pakistan Related Equipments: two PE600×900 jaw crushers, two impact crushers, two cone crushers, two sand makers and three circular vibrating screenswhat is screening process in iron oreMar 28, 2015 Iron ores normally fall within one of the three categories namely (i) direct shipping, or high grade ores, which contain enough iron to be charged to the iron making furnace directly and may only require crushing, screening, and blending, (ii) associated low grade merchant ores which occur around the high grade ores that can be mined Processes for Beneficiation of Iron Ores – IspatGuru

fine iron ore screening

Iron ore Know More Iron ores are rocks and minerals from which metallic iron can be economically extracted Mining of banded iron formations involves coarse crushing and screening, followed by rough crushing and fine grinding to comminute the ore to the point where the crystallized magnetite and quartz are fine enough that the quartz isIron Ore vibrating feeder,iron ore mining equipment The ZSW series Iron Ore vibrating feeder has made a lot of achievements Iron Ore vibrating feeder is widely used in the joint equipment of crushingscreening at the fields mineral processing, building materials, chemicals and gravel plant Read morewhat is feeder in iron ore screening plantIron ore dry screening process eduvijfnl iron ore dry screening process Iron processing depend mainly on the type of ROM ore feed and optimum product Dry screening into lumps and fines is practised for high quality flaky ore and blue dust because if wet treatment is What Is Screening Process In Iron OreIron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets These are typically fed to a blast furnace or DRI plant as part of the process to make steel Drums typically have very high recycle rates so have a screening circuit to screen out undersize and oversize pieces to be put back through Iron ore pelletizing systems Iron Ore Screening Multotec Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirementswhat is iron ore screening equipment ME Mining Machinery

Mechanical screening Wikipedia

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling A method of separating solid particles according to size alone is called screeningWhat is iron ore? Iron ores are rocks and minerals from which metallic iron can be extracted There are four main types of iron ore deposit: massive hematite, which is the most commonly mined, magnetite, titanomagnetite, and pisolitic ironstone These ores vary in colour from dark grey, bright yellow, or deep purple to rusty redIron ore BHP