Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

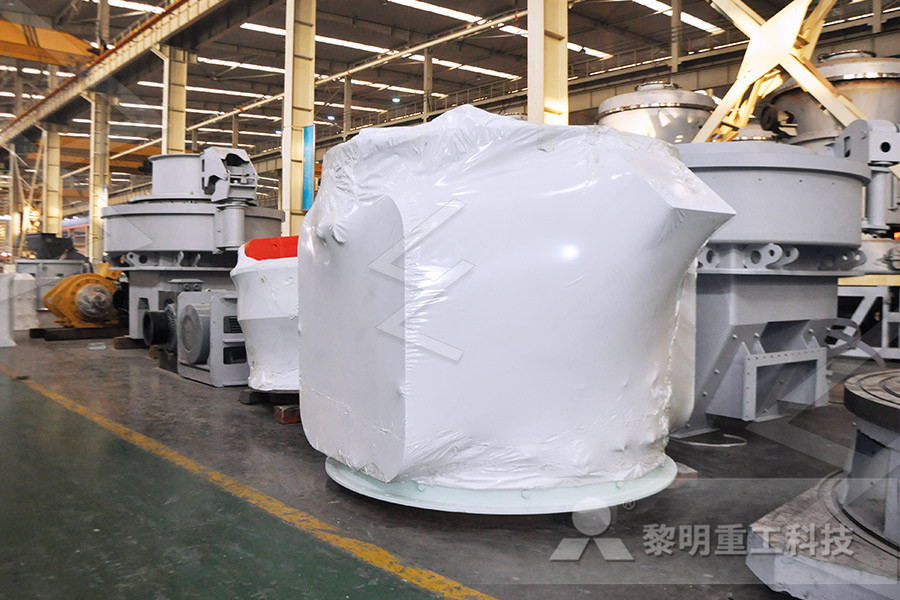

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

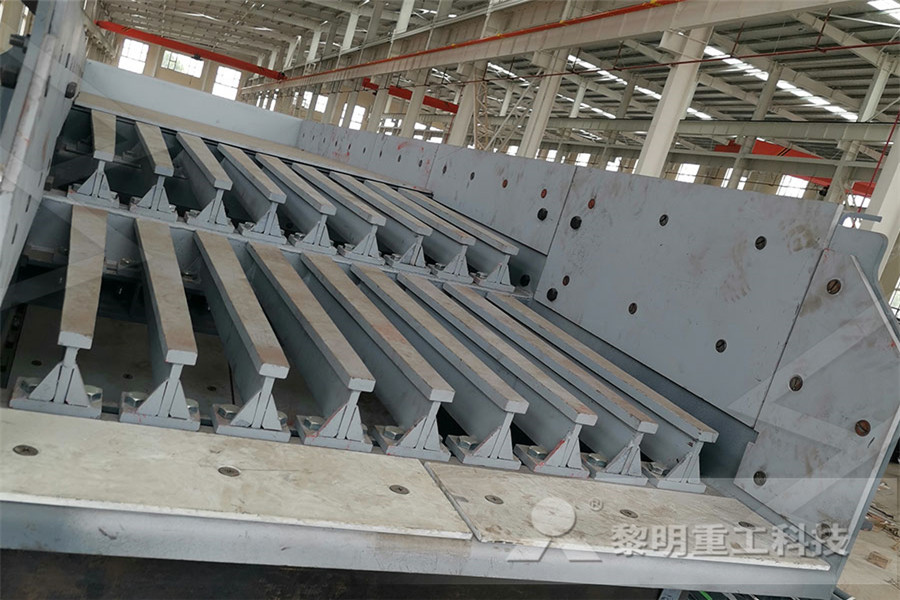

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Impact Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44)A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle (Figure 44(a)) and it is the most widely used in primary crushing stages (Behera et al, 2014)Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size is less than 500mm With end products in cubic shape, the impact crusher is widely used for sand and rock producing in the industry of roads, railways, reservoir, electricity power and Impact crusher,Impact breaker,Mobile impact crusher,Impact Here in the table, we can see it clearly that impact crusher has a larger inset opening size and different working principle of impaction While the jaw crusher has more models with different inset opening sizes, which means that jaw crusher is adaptable for different sizes of mines and plantsPortable and Fixed Impact Crusher Fote Machinery(FTM)Impact Crusher,By adopting the unique structural design, finished products processed by impact crusher boasts cubic shape without tension and cracks It can crush stone smaller than 500mm with compression strength lower than 350MPA, such as granite, limestone, concrete, etcImpact crusher, Impact crusher Machine, Impact crushing IMPACT CRUSHER 2 ADVANCED DESIGN, HIGH PERFORMANCE SECONDARY IMPACTOR Main working benefits of PF series Impact crusher Quick and easy installation Very simple design with high mechanical reliability on fullsize equipment in our Size Reduction Testing PlantPF SERIES IMPACT CRUSHER

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorThe impact crusher adopts closed circuit manifold cycles and makes sure the particle size of the materials is controlled by the screening equipment Impact crusher for salepurchasing tips There are many kinds of impact crushers in the market, so what are Impact Crusher With Various Models Fote Machinery(FTM)For instance, if the final size of your product only needs to be between 4 inches and 6 inches, a primary jaw or impact crusher can accomplish your goals However, you will likely require a much finer product, and that means incorporating up to three—or even four—stations with a variety of crusher types 1Types of Rock Crushers Quarry Crushing Equipment KemperImpact Crushers may be used as primary, secondary, or tertiary crushers depending on the Producer’s finalproductsize needs Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industriesWhat is an Impact Crusher? Telsmith2001 Portable Vertical Shaft Impact Crusher – ISC (Impact Service Corp) Model 103 (1) – one – 2001 ISC (Impact Service Corp) Portable Model 103 Vertical Shaft Impact Crusher, 700 hp (twin 350 hp motors), 5 shoe 45” diameter table with anvil ring, 42” wide rear discharge conveyor with hingeUsed Portable Impact Crusher for sale Trio equipment

IMPACT CRUSHERS Power Equipment Company

The 4800 Series Impact Crushing Plants from are the ultimate, completely selfcontained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other CD debris The heart of the plant is a 4248LP Impact Crusher, aIn the back of the production of impact crusher in the process of constructing basic attribute, the plate hammer velocity and crushing material finished product size, equipment and the plate hammer wear are closely linked impact crusherso how to reasonable optimization has become the key point of promoting the counter productive efficiency Impact Crushers Design And CalculationsImpact Crushers =High Crushing ratio upto 80 saving installation cost and can be worn down to 70% of their original size The impact walls are arranged around the rotor and are equipped with renewable grinding ledges of wear resistant cast material The final product of the crusher can beMODEL KR Bar Arrangement Impact CrushersThe impact crusher adopts closed circuit manifold cycles and makes sure the particle size of the materials is controlled by the screening equipment Impact crusher for salepurchasing tips There are many kinds of impact crushers in the market, so what are Impact Crusher With Various Models Fote Machinery(FTM)The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty requiredImpact Crusher Manufacturers Mumbai, India

Impact Plate Design GitHub Pages

For impact crusher with twostage impact plate, we can set the first impact plate according to the incidence angel d=0 and the size of feed opening Turn the blow bar about 25° from the unloading point, and then considering the incidence angel as 0 and the minimum size of discharge opening and the corresponding angle, we can determine the IMPACT CRUSHER 2 ADVANCED DESIGN, HIGH PERFORMANCE SECONDARY IMPACTOR Main working benefits of PF series Impact crusher Quick and easy installation Very simple design with high mechanical reliability on fullsize equipment in our Size Reduction Testing PlantPF SERIES IMPACT CRUSHERAt only 150 lbs, the 911MPEIC4000 is an ultra portable BLOWBAR TYPE impact crusher The impact crusher can easily fine crush a feed of 3/4″ at some 250 kilo/hr The crushing cage on this impactor is about 55″ inside X 14″ x 14″ Impact Crusher, no motor, no mounting frame (Baseline): —– Impact Crusher as shown, with motor and Hammer Mill Grinder 911Metallurgistthe material to a desired product size Historically, cone and roll crushers were the most common choice crushers, but in recent years impact crushers are more widely used These crushers also are sometimes used as primary crushers for finegrained gravel deposits The cone crusher (a compression type) simply crushes the aggregate between5 Aggregate Production INgovThe feed may not be entering the crusher at the proper angle as it shouldn't initially hit the rotor directly Try using one machine that can do the entire size reduction job, which will save money and improve your process Cage mill crushers can achieve up to 40to1 size reduction ratios Problem: Labor costs are too Most Common Problems With Size Reduction Equipment

Impact Crusher Professional Crusher Plant Manufacturer

The impact crusher can process various coarse, medium and fine materials with a crushing feed size of not more than 500mm and a compressive pressure of not more than 350Mpa When it increases the number of material hits, hard extrusion, friction reduction, Quick to install and maintain Minimal foundation requirements, maintenance lifting tools, and inspection door for rotor access Safe to operate Special tools for rotor service and crusher top half lifting Features Barmac® B9100SE™ vertical shaft impact (VSI) crusher for precise size Barmac® B9100SE™ vertical shaft impact (VSI) crusher Components Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc Vibration Feeder: These machines feed the jaw and impact crusher Crushing plant WikipediaJan 01, 2016 The operation is similar to the standard cone crushers, except that the size reduction is caused more by attrition than by impact The reduction ratio is around 8:1 and as the product size is relatively small the feed size is limited to less than 50 mm with a nip angle between 25° and 30°Gyratory and Cone Crusher ScienceDirectIn the back of the production of impact crusher in the process of constructing basic attribute, the plate hammer velocity and crushing material finished product size, equipment and the plate hammer wear are closely linked impact crusherso how to reasonable optimization has become the key point of promoting the counter productive efficiency Impact Crushers Design And Calculations

MODEL KR Bar Arrangement Impact Crushers

Impact Crushers =High Crushing ratio upto 80 saving installation cost and can be worn down to 70% of their original size The impact walls are arranged around the rotor and are equipped with renewable grinding ledges of wear resistant cast material The final product of the crusher can beThe impact crusher can process various coarse, medium and fine materials with a crushing feed size of not more than 500mm and a compressive pressure of not more than 350Mpa When it increases the number of material hits, hard extrusion, friction reduction, Impact Crusher Professional Crusher Plant Manufacturer The extremely rugged construction of Impact Crushers ensures a long life with minimum maintenance easy to install and economical to run The shell of Impact Crusher is lined throughout with MS, Cast Iron or Manganese Steel, according to the size of Impact Crusher and duty requiredImpact Crusher Manufacturers Mumbai, Indiaimpact crushers worldwide demonstrate the efficiency, reliability and thus the primary crushers for feed size up to 1,400 mm With excellent design features and func Compact design for installation •in confined space conditions •in mobile or semimobile plants Serviceability due to Prallbr EQuick to install and maintain Minimal foundation requirements, maintenance lifting tools, and inspection door for rotor access Safe to operate Special tools for rotor service and crusher top half lifting Features Barmac® B9100SE™ vertical shaft impact (VSI) crusher for precise size Barmac® B9100SE™ vertical shaft impact (VSI) crusher

Impact Plate Design GitHub Pages

For impact crusher with twostage impact plate, we can set the first impact plate according to the incidence angel d=0 and the size of feed opening Turn the blow bar about 25° from the unloading point, and then considering the incidence angel as 0 and the minimum size of discharge opening and the corresponding angle, we can determine the Vertical shaft impact crusher is widely used in all kinds of minerals It provides the better quality sand and crushed stone aggregate to the highspeed railroad, highrise construction, municipal administration construction, water and electricity dam construction, concretes agitation stationVertical Shaft Impact Crusher,VSI Vertical Shaft Impact the material to a desired product size Historically, cone and roll crushers were the most common choice crushers, but in recent years impact crushers are more widely used These crushers also are sometimes used as primary crushers for finegrained gravel deposits The cone crusher (a compression type) simply crushes the aggregate between5 Aggregate Production INgovComponents Crushing plants make use of a large range of equipment, such as a prescreener, loading conveyor, intake hopper, magnetic separator, crushing unit, such as jaw crushers and cone crusher etc Vibration Feeder: These machines feed the jaw and impact crusher Crushing plant WikipediaJan 01, 2016 The operation is similar to the standard cone crushers, except that the size reduction is caused more by attrition than by impact The reduction ratio is around 8:1 and as the product size is relatively small the feed size is limited to less than 50 mm with a nip angle between 25° and 30°Gyratory and Cone Crusher ScienceDirect

Mobile Impact Crushers Striker Built To Last

impact crusher Well proven high performance impactor featuring heavyduty open disc style rotors with four blow bars as standard Blow bar support beams sized 3 Crushing cone or fixed cone liner is not round and generates impact 3 Check the roundness of the liner during installation and machining if necessary Crusher with load suddenly stopped 1The oil temperature rises, the oil level and oil pressure are too low, causing the relay worksSymons Cone Crusher With Large Capacity Fote Machinery(FTM)High chromium steel is widely used in casting impact crusher wear parts The impact crusher wear parts include crusher blow bar and impact plate As normal, Cr21 and Cr26 are used in casting crusher blow bars; the Cr15 material used in casting impact plate Ceramic Matrix Composites Blow Bar Ceramic Matrix Composites Blow Bar is one of the Impact Crusher Wear Parts Qiming Machinery