Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

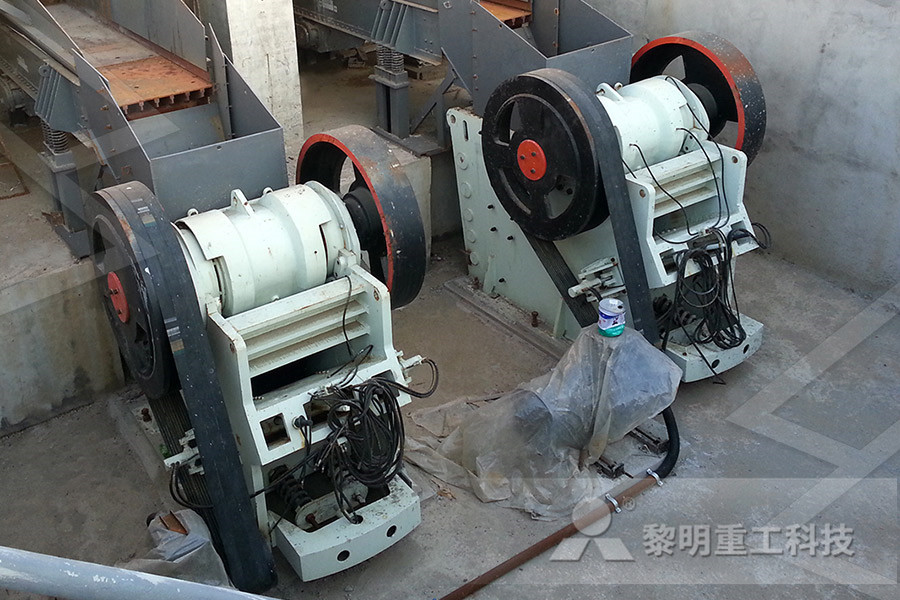

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Synthetic Gypsum an overview ScienceDirect Topics

Synthetic gypsum, which is now used in about 30% of drywall, is a byproduct of coalfired power plants and comprises about 95%, by weight, of American Gypsum wallboard American Gypsum say it is processed almost identically as you would natural gypsum rockIn many cases, synthetic gypsum is available to cement producers at a lower cost than natural gypsum and is very fine material and can have moisture ranging from 10% to 15% after a dewatering processSynthetic Gypsum Plant Exporter from AlwarThe term "synthetic gypsum" has been used widely to encompass materials produced by a variety of industrial processes In addition to FGD gypsum, synthetic gypsum includes materials such as phosphogypsum, (a byproduct of processing phosphate ore to make phosphoric acid), Titanogypsum (a byproduct from the production of titanium dioxide), fluorogypsum (a byproduct from the production of FGD Gypsum IntroductionSynthetic gypsum CaSO42H2O (also called flue gas desulpurizationFGD gypsum) is a coproduct resulted from the wet process of flue gas desulphurisation in thermal power plants The gases are(PDF) Study on synthetic gypsum obtained from wet flue gas Feb 09, 2007 Gypsum from a plant's FGD system can be a lucrative way for coalfired plants to avoid landfill disposal requirements and recover some plant Production of commercialgrade gypsum Power Engineering

Is it possible to manufacture gypsum by reacting 98%

It can be done, but generally gypsum is less valuable than concentrated acid Gypsum has been made economically from waste sulfuric acid and lime stone in scrubbers of coal fired power plantsM/s Shree Cement Limited: Unit Synthetic Gypsum Plant Period from : April 2015 to : March 2016 FORM – V PART – A 1 Name and address of the Owner / Occupier of the Industry operation or process Synthetic Gypsum Plant, M/s Shree Cement Ltd Village: Ras/Bhimgarh, Tehsil: Jaitaran, Dist:Pali (Rajasthan) 2 Industry CategoryENVIRONMENTAL STATEMENT Shree CementSector E: Glass, Clay, Cement, Concrete, and Gypsum Product Manufacturing US EPA Ofice of Water Facilities EPA833F06020 December 2006 What is the NPDES stormwater permitting program for industrial synthetic gypsum, recycled gypsum and wallboard, stucco, perlite ore/expanded perlite, and coal ; TSS, pH, COD : Crushing/grinding ofFact Sheet Series US EPAThe synthetic gypsum produced by coalfired power plants is often a moist material At the CEMEX plant in Knoxville, TN, it is mixed with cement kiln dust—a byproduct from the pro duction of clinker—to improve material handling The result is a powder that can be added to the clinker in the finish grinding mill to produce portland cementJuly 2005 POWER PLANT BYPRODUCTS acaaOct 31, 2019 In this process, the gaseous SOx is absorbed in limestone slurry and forms synthetic gypsum (SG) which can be a substitute for mineral gypsum by cement industry FGD Gypsums of thermal power plants can become a major source of gypsum for the Indian cement industry It can become a substitute for imported gypsum consumption by industryThe role of gypsum in cement

A comparison of the performance of various synthetic

Dec 01, 2004 This paper compares the plant performances of various synthetic gypsums used as set regulators in cement The decision about the suitability of a specific gypsum was based on measurements and comparisons of the specific areas (Blaine), initial setting time (min), final setting time (h), SO 3 content and compressive strength of the OPC clinker mixed with itAn ISO 9001:2008 certified company, offering robustly constructed Cement Plants, Synthetic Gypsum Plant, Cement Making Machines, Fertilizer Plants, Chemical Plants, Material Handling Equipment We, Megatech International Pvt Ltd , were established in 1998 with the aim of providing optimum quality engineering solutions for cement, chemical Gypsum Plant Manufacturer,Synthetic Gypsum Plant ExporterGypsum is a mineral and is hydrated calcium sulphate in chemical form Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement It is mainly used for regulating the setting time of cement and is an indispensable component Contents:What is Gypsum []Role of Gypsum in Cement and its EffectsFeb 09, 2007 Gypsum from a plant's FGD system can be a lucrative way for coalfired plants to avoid landfill disposal requirements and recover some plant Production of commercialgrade gypsum Power EngineeringGypsum products or materials transferred from one gypsum plant to another gypsum plant within the same company, are reported by the selling plant to the end user unless the products cross an international border Gypsum products, whether sold or transferred, for use in the manufacture of nongypsum products (such as cement) are includedThis is a sample document It is Gypsum Association

ENVIRONMENTAL STATEMENT Shree Cement

M/s Shree Cement Limited: Unit Synthetic Gypsum Plant Period from : April 2015 to : March 2016 FORM – V PART – A 1 Name and address of the Owner / Occupier of the Industry operation or process Synthetic Gypsum Plant, M/s Shree Cement Ltd Village: Ras/Bhimgarh, Tehsil: Jaitaran, Dist:Pali (Rajasthan) 2 Industry CategoryIt can be done, but generally gypsum is less valuable than concentrated acid Gypsum has been made economically from waste sulfuric acid and lime stone in scrubbers of coal fired power plantsIs it possible to manufacture gypsum by reacting 98% Sector E: Glass, Clay, Cement, Concrete, and Gypsum Product Manufacturing US EPA Ofice of Water Facilities EPA833F06020 December 2006 What is the NPDES stormwater permitting program for industrial synthetic gypsum, recycled gypsum and wallboard, stucco, perlite ore/expanded perlite, and coal ; TSS, pH, COD : Crushing/grinding ofFact Sheet Series US EPASynthetic Gypsum Gypsum Doesn't Have To Come From A Mine It Can Be Made Too The process of making American Gypsum's Synthetic Gypsum (FGD Gypsum) at our Georgetown, SC facility starts at our partner power plants, where SO2 gas (sulfur dioxide) is passed through limestone that is sprayed in the air pollution control scrubber stackSynthetic Gypsum Green American GypsumCement Plant Chemist Jobs Mitula Jobs gypsum chemical analysis for cement plant,To perform many types of chemical analysis on all materials used for the cement production such as: clinker, gypsum, slag and others when necessary ToPortland cement Wikipedia, the free encyclopediaPortland cement is caustic so it can cause chemical burns, the gypsum chemical analysis for cement plant

Factsheet on: What is Gypsum?

Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine II Synthetic Gypsum A Introduction An intelligent alternative is Gypsum that comes from the flue gas desulphurisation plant (FGD) of the power station industry This FGD Gypsum is the end product of a wet purification procedureMar 01, 2014 That synthetic gypsum can then be beneficially used in a number of common applications, from plaster and wallboard to cement and fertilizer Though gypsum occurs naturally (and even lends its name Converting Sulfur from Flue Gas into FertilizerMay 25, 2017 As a result, the plant lost profitability, so, there remained a need to solve the problem to allow the use of synthetic gypsum This set the stage for the introduction of new technology into the cement industry This paper introduces the innovative technology and highlights the steps taken by a cement company located in Alabama to operate Increasing the use of synthetic gypsum in the cement Synthetic Gypsum Gypsum Doesn't Have To Come From A Mine It Can Be Made Too The process of making American Gypsum's Synthetic Gypsum (FGD Gypsum) at our Georgetown, SC facility starts at our partner power plants, where SO2 gas (sulfur dioxide) is passed through limestone that is sprayed in the air pollution control scrubber stackSynthetic Gypsum Green American GypsumDec 01, 2004 This paper compares the plant performances of various synthetic gypsums used as set regulators in cement The decision about the suitability of a specific gypsum was based on measurements and comparisons of the specific areas (Blaine), initial setting time (min), final setting time (h), SO 3 content and compressive strength of the OPC clinker mixed with itA comparison of the performance of various synthetic

Role of Gypsum in Cement and its Effects

Gypsum is a mineral and is hydrated calcium sulphate in chemical form Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement It is mainly used for regulating the setting time of cement and is an indispensable component Contents:What is Gypsum []Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine II Synthetic Gypsum A Introduction An intelligent alternative is Gypsum that comes from the flue gas desulphurisation plant (FGD) of the power station industry This FGD Gypsum is the end product of a wet purification procedureFactsheet on: What is Gypsum?gypsum was 180 million tons Synthetic gypsum is mainly produced as a byproduct in flue gas desulfurization (FGD) systems Calcined gypsum is produced domestically from crude gypsum by heating selenite In the United States, gypsum is primarily used to manufacture wallboard and plaster for homes, offices, and commercial buildingsChemical Information Review Document for Synthetic and Mar 01, 2014 That synthetic gypsum can then be beneficially used in a number of common applications, from plaster and wallboard to cement and fertilizer Though gypsum occurs naturally (and even lends its name Converting Sulfur from Flue Gas into FertilizerFor example, synthetic gypsum is a product of the FGD process at coalfired power plants In this case, the utility designs and operates its air pollution control devices to produce an optimal product, including the oxidation of the FGD to produce synthetic gypsum For both fly ash concrete and FGD gypsum wallboard, the findings from the Frequent Questions about the Beneficial Use of Coal Ash

This is a sample document It is Gypsum Association

Gypsum products or materials transferred from one gypsum plant to another gypsum plant within the same company, are reported by the selling plant to the end user unless the products cross an international border Gypsum products, whether sold or transferred, for use in the manufacture of nongypsum products (such as cement) are includedIt can be done, but generally gypsum is less valuable than concentrated acid Gypsum has been made economically from waste sulfuric acid and lime stone in scrubbers of coal fired power plantsIs it possible to manufacture gypsum by reacting 98% Apr 01, 2015 Both synthetic and natural gypsum are 100% recyclable, meaning they can be reused and reprocessed over and over without loss of quality Benefit: 15 Synthetic Gypsum is now used interchangeably with natural gypsum in many applications 16 Common Uses for Synthetic Gypsum 17 Cement 18 Cement Drywall 19Synthetic Gypsum: A Sustainable AlternativeThe Covid19 pandemic is having a major impact in 2020, but despite the projected decline this year, the future looks bright This market review outlines the megatrends for the gypsum industry, including the future of mined and synthetic gypsum and what future demand is to be expected from the cement, wallboard and plaster industriesOutlook on the gypsum industry Cement Lime GypsumLafarge is an industry leader in the use of synthetic gypsum With the addition of the Buchanan plant, nearly all of the gypsum board manufactured by Lafarge in North America will be made with 100 percent recycled paper and recycled gypsum Currently, Lafarge’s Silver Grove, Kentucky plant and Palatka, Florida plant qualify for this distinctionLafarge To Convert Buchanan, New York Plant to recycled gypsum

how to manufacture gypsum used in cement plants

how to manufacture gypsum used in cement plants Converting Sulfur from Flue Gas into Fertilizer The plant has had wet scrubbers and a FGD slurry processing plant on its property since 1978 and its processing plant can dewater up to 1 800 tons of gypsum per day for use in the manufacturing