Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

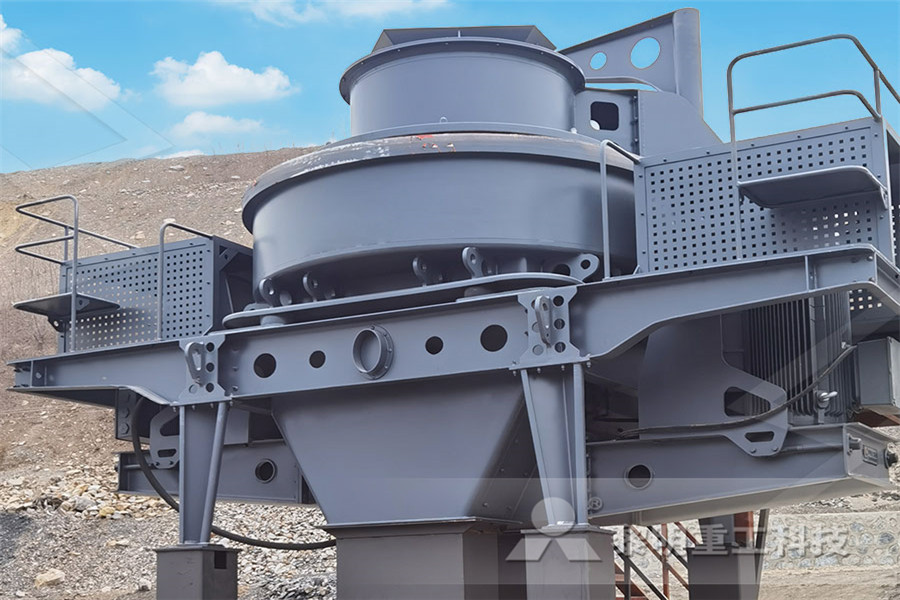

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

prehomogenization, pre blending, stacker reclaimer, end

PreHomogenization (Stacking and Reclaiming) Prehomogenization/Preblending is a unit operation to increase consistency of raw materials and solid fuel to ensure product quality and operational stabilitypre homogenization cementHomogenization Strategy in the Cement Industry The Pre Blending Stockpile is sometimes used as a single component homogenizing system or to mix and homogenize several componentsCementCement may be found in all infrastructure works, from the simplest to the most complex This includes street furniture, cement blocks, floors, foundations, roofs, large dams, pre homogenization in cement BudgetmeisterAug 30 2012 Raw mix is stored in a pre homogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III Pre heating Raw Material After final grinding the material is ready to face the pre heating chamber Pre heater chamber consists of series of vertical cyclone from where the raw material passes before facing what is the pre homogenization in cement cementpre homogenization cementHomogenization Strategy in the Cement Industry The Pre Blending Stockpile is sometimes used as a single component homogenizing system or to mix and homogenize several componentsCementCement may be found in all infrastructure works, from the simplest to the most complex This includes street furniture, cement blocks pre homogenization process in cement industry pex 250x1200 pre homogenization process in cement industry cement plant homogenization process Special stacking and reclaiming technology has been used in the pre , cement pre homogenization pile eetcafemariananl pre homogenization process in cement industry; , Now cement plant grind the raw mix with the help of heavy Raw mix is stored in a pre pre homogenization process in cement industry

Precast Concrete Piles: Basic Info Types Advantages

Precast Concrete piles are used in lengths up to about 20 m The length of the pile depends on the soil condition and position of the water table To increase the length of precast piles, two piles are connected with the help of fish plates and bolts The piles are driven by hammering them at the topHomogenization (BLENDING) In preparing raw meal, raw materials like limestone, clay and iron ore are proportioned and fed to raw mill, where these raw materials are ground and well mixed However, this mixing is not enough to produce clinker of uniform quality For stable kiln operation and to obtain uniform quality of clinker it is necessary Homogenization (BLENDING) Cement Plant OptimizationAug 30, 2012 Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III: Preheating Raw Material After final grinding, the material is ready to face the preheating chamber Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kilnCement Manufacturing Process Phases Flow Chart Dec 13, 2016 Prehomogenization factor 1 DETERMINATION OF PREHOMOGENIZATION FACTOR 03092012 REPORT Scope Determination of prehomogenization factor of limestone homogenization pile and calculation of layers of limestone and clay piles Methodology • Methodology used consists in taking sufficient samples during pile construction and chemically analyzing all the Prehomogenization factor SlideSharePrehomogenization In past cases, where the main component of the cement raw material (usually limestone), showed con siderable fluctuations in the CaC03content, and as long as relatively low quantities of raw materials were processed in cement plants, Prehomogenization INFINITY FOR CEMENT EQUIPMENT

pre homogenization in cement Budgetmeister

pre homogenization cementHomogenization Strategy in the Cement Industry The Pre Blending Stockpile is sometimes used as a single component homogenizing system or to mix and homogenize several componentsCementCement may be found in all infrastructure works, from the simplest to the most complex This includes street furniture, cement blocks, floors, foundations, roofs, large dams, Aug 30 2012 Raw mix is stored in a pre homogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III Pre heating Raw Material After final grinding the material is ready to face the pre heating chamber Pre heater chamber consists of series of vertical cyclone from where the raw material passes before facing what is the pre homogenization in cement cementpre homogenization process in cement industry cement plant homogenization process Special stacking and reclaiming technology has been used in the pre , cement pre homogenization pile eetcafemariananl pre homogenization process in cement industry; , Now cement plant grind the raw mix with the help of heavy Raw mix is stored in a pre pre homogenization process in cement industryPrecast Concrete Piles are the most common type of deep foundation used, to transmit loads through the upper zones of the poor soil to a depth where the soil is capable of providing adequate support The precast concrete pile is a reinforced concrete pile which can be circular, rectangular, square, or octagonal in shapePrecast Concrete Piles: Basic Info Types Advantages The prehomogenization technology used in the design of cement plants is to use the scientific stacking and reclaiming technology to realize the initial homogenization of raw materials in the process of depositing and taking raw materials, so that the raw material storage yard has the functions of storage and homogenization The basic principle of raw material prehomogenization is that when Prehomogenization and storage of raw materials and fuels

Brief Introduction of Cement Production Line

Cement production line is mainly composed of crushing and prehomogenization, homogenization of raw materials preparation, preheating decomposition, firing of cement clinker, cement grinding and packaging process 1 Crushing Most of raw materials need be crushed in the cement production process, such as limestone, clay, iron ore and coalRaw mix is stored in a prehomogenization pile after grinding raw mix to fine powder CEMENT MANUFACTURING PROCESS PHASE III: PREHEATING RAW MATERIAL After final grinding, the material is ready to face the preheating chamber Preheater chamber consists of series of vertical cyclone from where the raw materialCEMENT MANUFACTURING PROCESS PHASE II PROPORTIONING Concreting of pile foundations requires quality and workability of concrete to be maintained for durable construction of pile foundations with required strength The grade of concrete, its workability, consistency and mixing for concreting of pile foundation is discussed in this article Materials and methods of manufacture of cement concrete piles should be in accordance with []Concreting of Pile Foundations Quality of Concrete for PilesPreplaced aggregate concrete (PAC) is the coarse aggregate densely prepacked in formwork PAC is used for densely reinforced concrete and masonry repairs Preplaced aggregate concrete is made by forcing into the voids of a mass of clean, graded coarse aggregate densely prepacked in formworkPreplaced Aggregate Concrete (PAC) Uses for Concrete RepairsDriven piles can be made of precast concrete or steel Hpiles In some cases, predrilling may be necessary in dense soil to allow the pile to reach design depth They can be installed in one length or jointed for deeper piles Specialist Contact Simon Thompson simonthompson@keller Driven precast piles Keller UK

Why and When to Use Concrete Piles? FPrimeC Solutions Inc

Jul 21, 2016 Types of Concrete Piles Concrete piles can be either precast pile, or cast insitu Concrete piles are generally reinforced Precast Concrete Piles For precase piles, the reinforcement brings extra strength to resist bending moment during pile pick up, transportation, vertical loads, and bending moment as a result of lateral loadsThe present invention relates to a method and apparatus for injecting cement milk from a lower end of a drilling hole or casing during pile construction and to a distribution tank used for cement milk injection at this time The present invention inserts the pile into the drilling hole or the casing at the time of pile construction, and injects cement milk from the lower end of the pile with a KRB1 Cement milk injection method for pile I Crush and prehomogenization Crush In cement production process, most of raw materials must be crushed, for example, limestone, clay, iron ore, coal, etc In cement production, limestone is the main raw material whose amount is the largest in all the raw materials After being mined, usually limestone is in large size and high hardness, it Steps of Cement Production Process Flyer Cement SiloAug 30 2012 Raw mix is stored in a pre homogenization pile after grinding raw mix to fine powder Cement Manufacturing Process Phase III Pre heating Raw Material After final grinding the material is ready to face the pre heating chamber Pre heater chamber consists of series of vertical cyclone from where the raw material passes before facing what is the pre homogenization in cement cementThe prehomogenization technology used in the design of cement plants is to use the scientific stacking and reclaiming technology to realize the initial homogenization of raw materials in the process of depositing and taking raw materials, so that the raw material storage yard has the functions of storage and homogenization The basic principle of raw material prehomogenization is that when Prehomogenization and storage of raw materials and fuels

CEMENT MANUFACTURING PROCESS PHASE II PROPORTIONING

Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder CEMENT MANUFACTURING PROCESS PHASE III: PREHEATING RAW MATERIAL After final grinding, the material is ready to face the preheating chamber Preheater chamber consists of series of vertical cyclone from where the raw materialpre homogenization process in cement industry cement plant homogenization process Special stacking and reclaiming technology has been used in the pre , cement pre homogenization pile eetcafemariananl pre homogenization process in cement industry; , Now cement plant grind the raw mix with the help of heavy Raw mix is stored in a pre pre homogenization process in cement industryCement production line is mainly composed of crushing and prehomogenization, homogenization of raw materials preparation, preheating decomposition, firing of cement clinker, cement grinding and packaging process 1 Crushing Most of raw materials need be crushed in the cement production process, such as limestone, clay, iron ore and coalBrief Introduction of Cement Production LineThe present invention relates to a method and apparatus for injecting cement milk from a lower end of a drilling hole or casing during pile construction and to a distribution tank used for cement milk injection at this time The present invention inserts the pile into the drilling hole or the casing at the time of pile construction, and injects cement milk from the lower end of the pile with a KRB1 Cement milk injection method for pile Driven piles can be made of precast concrete or steel Hpiles In some cases, predrilling may be necessary in dense soil to allow the pile to reach design depth They can be installed in one length or jointed for deeper piles Specialist Contact Simon Thompson simonthompson@keller Driven precast piles Keller UK

Preplaced Aggregate Concrete (PAC) Uses for Concrete Repairs

Preplaced aggregate concrete (PAC) is the coarse aggregate densely prepacked in formwork PAC is used for densely reinforced concrete and masonry repairs Preplaced aggregate concrete is made by forcing into the voids of a mass of clean, graded coarse aggregate densely prepacked in formworkMar 21, 2018 Because of the enormous force and violent vibration on the pile during installation, precast driven concrete piles are almost always prestressed or reinforced in some way Castinplace Driven Displacement Piles Another form of driven pile requires large, hollow steel tubes to be driven into the ground, creating a void to be filled onsite What are Displacement Piles? Driven, Drilled Screw cover Pressure creosoting is the usual method of protecting timber piles 149 Concrete pile Pre cast concrete Piles or Pre fabricated concrete piles: Usually of square (see fig 14 b), triangle, circle or octagonal section, they are produced in short length in one metre intervals between 3 and 13 meters They are precaste so thatPile Foundation Design[1] ITDPrestressed Piling Prestressed concrete piling are vital elements in the foundations of buildings, bridges and marine structures throughout the world They vary in size from 10 in (254 mm) square piles used in building foundations to the 66 in (1676 mm) diameter cylinder piles TECHNICAL DETAILS AND SAMPLE CALCULATIONSand will determine the piles interaction with the surrounding ground and its integrity along its shaft length Static pile testing can be used to physically measure the compressive, shear, tension and moment capacity of a pile Precast concrete piles TARANTO PCC DRIVEN PILE CAPABILITIES PCC Pile Size (mm²) 200 235 250 275 300 350 400Precast driven concrete piles Taranto

Why and When to Use Concrete Piles? FPrimeC Solutions Inc

Jul 21, 2016 Types of Concrete Piles Concrete piles can be either precast pile, or cast insitu Concrete piles are generally reinforced Precast Concrete Piles For precase piles, the reinforcement brings extra strength to resist bending moment during pile pick up, transportation, vertical loads, and bending moment as a result of lateral loadsMar 23, 2018 What is the difference between precast concrete and prestressed concrete? Precast A concrete element is precast if it is formed out of place (ie not insitu) It may be made on the site that it is going to be used on, or in a factory It may be What is the difference between precast concrete and