Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

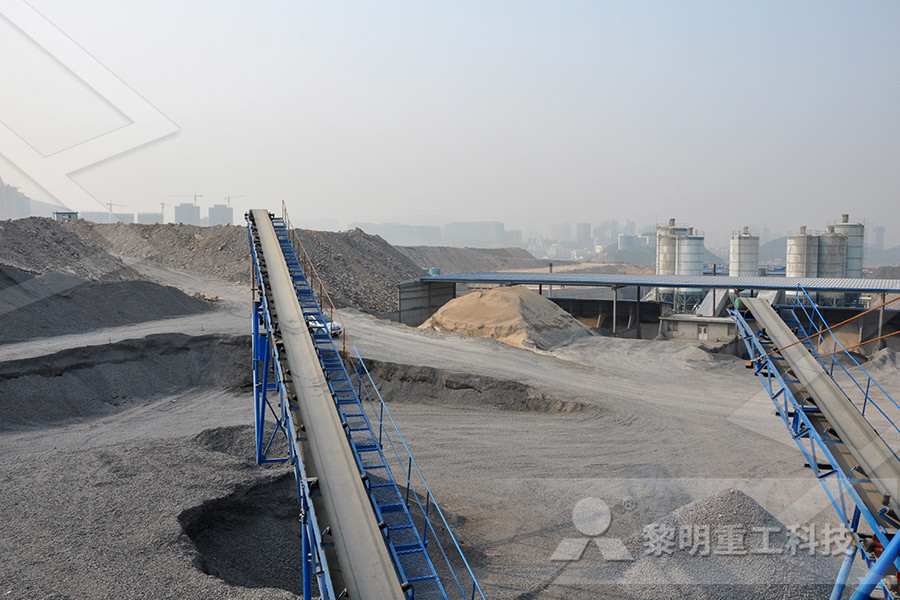

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Roller mills: Precisely reducing particle size with

The roller mill minimizes such costs by precisely reducing feed materials with an average particle size up to 3⁄ 4inch to a uniform average size typically between 100 and 2,000 micronsroller mill and particles sizes and speed differential Roller Mill Criteria for Proper Processing Desired corrugations per inch of roll being: 8 to 10 for , 10 to 12 for wheat, barley, and oats, and 12 to 14 for milo; Particle size controlled by The setting of the rollers, Corrugations, spiral roller versus nonspiral, and Speed roller mill and roll speed differential griffonnerJan 11, 2016 The speed differential between the rolls Crumbler – A roller mill specially designed for breaking up pellets into smaller particles Two variants of roller mill are recognized and they are; a Multiple or corrugated rollers Methods of Size Reduction and Factors Affecting Size Reduction in Pharmaceutics International Research Journal Roller Mill: Components, Designs, Uses, Advantages and Particle Size and Standard Deviation Roller Mill and Hammermill on Corn US #2 Yellow Corn 300 400 500 600 700 800 900 1000 2 25 3 35 or coarse particles, etc Typical differential with a fast roll speed of 1,000 RPM would haveParticle Size and Standard DeviationTo obtain the desired particles size, the following should be controlled: The gap between the rollers The speed differential or constant crush between the rolls Feed rate The gearing of rollers in a roller mill have 2 options – one slow mill and one fast one for differential for shearing or rolls running at same speed for flattening / flakingRoller Mill AFSystems

Roller mill Feed Mill Machinery Glossary FeedMachinery

In addition, the roll faces can be grooved to further take advantage of the speed differential and improve size reduction By placing (stacking) pairs of rolls on top of one another, two or three high, it is possible to reduce particle sizes down to 500 microns, duplicating the sizereducing capability of a Jul 17, 2020 Mills in which the rotor speed is approximately 1,800 rpm, hammers should be about 10 inches (≈ 25 cm) long, 25 inches (≈ 635 cm) across, and 025 inches (≈ 64 mm) thick For a rotor speed about 3,600 rpm, hammers should be 6 to 8 inches (≈ 15 to 20 cm) long, 2 inches (≈ 5 cm) across, and 025 inches (≈ 64 mm) thickHammermills and Roller Mills EngormixMar 01, 2020 At this ratio, the fixed, driven roller is reduced to the circumferential speed of the movable roller The upper limit of the circumferential speed is around 6 ms −1 Typically, corrugated and smooth rollers with a standard diameter have a circumferential speed of 33–44 ms −1 during wheat and rye milling (at 250–360 rpm) ( Meuser Stone milling versus roller milling: A systematic review Roller mills reduce particle size by: The rolls move with a differential drive of one roll moving 50 to 75 percent faster than the other Rolls have corrugations to help slice the grain, Corrugations have a 1 to 2inch spiral to increase the shearing potential and eliminate finesMeasuring Feed Particle Size Iowa PorkDifferential roller mills sample size Roller mill and particles sizes and speed differential Differential roller mills sample sizedifferential roller mills sample size Feed grinder mill grinder sample size from 02 to 25 kg Industrial machinery raymond grinding mill for pyrophylliteDifferential Roller Mills Sample Size

Roller Mill AFSystems

To obtain the desired particles size, the following should be controlled: The gap between the rollers The speed differential or constant crush between the rolls Feed rate The gearing of rollers in a roller mill have 2 options – one slow mill and one fast one for differential for shearing or rolls running at same speed for flattening / flakingrollers, roller diameter, speed and corrugation pattern Generally, roller mills grind grain into more uniformly sized particles than hammer mills (Figure 6) Figure 5 Roller mill Image courtesy CPM Roskamp Champion Roll pair Second roll pair Delivery device Figure 6 Difference in particle size distribution between a hammer mill and a FEED GRANULOMETRY AND THE IMPORTANCE OF FEED In a roller mill, particles are subjected to shear and compressive forces (Haque 1991) Segregation between the kernel parts occurs in plansifters, where sieves separate particles of different size, and in purifiers, where sieves and airflow separate particles of different sizeUsing the eightroller mill in the purifierless mill flowJul 17, 2020 In addition, the roll faces can be grooved to further take advantage of the speed differential and improve size reduction By placing (stacking) pairs of rolls on top of one another, two or three high, it is possible to reduce particle sizes down to 500 microns, duplicating the sizereducing capability of a hammermill for grainHammermills and Roller Mills EngormixMar 01, 2020 At this ratio, the fixed, driven roller is reduced to the circumferential speed of the movable roller The upper limit of the circumferential speed is around 6 ms −1 Typically, corrugated and smooth rollers with a standard diameter have a circumferential speed of 33–44 ms −1 during wheat and rye milling (at 250–360 rpm) ( Meuser Stone milling versus roller milling: A systematic review

Particle Reduction Technology For a ly Changing World

Nov 01, 2005 For example, compare roller mills with hammermills, or Fitzmills®, which grind by impact at high speeds and rely on a perforated sizing screen to control particle size Roller mills typically create 5075% less dust, or “fines”, and improve desired particle uniformity by 50100%In roller mills, wheat seeds are grinded in the gristing phase by pairs of fluted rollers, thus being obtained a wide range of particles with sizes from 2000 µm, , consisting in coat particles (of larger sizes) and endosperm particles (of smaller sizes), to be further separated with plansiftersGrinding Characteristics of Wheat in Industrial Mills The particle size and its distribution should be continuously monitored and recorded Particle size is critical to quality factors (CTQ) to a pellet press Because it influences both feed quality (PDI) and productivity Specific Energy of Hammer mill; It is a measure of the actual productivity of grinding equipment, (Hammer mill or roller mill)Art of GrindingParticle size reduction Benison Mediaresearch people and actual tasks on multidisciplinary sciences 12 – 16 june 2013, lozenec, bulgaria 400 variation of grist particle size obtained in the breakage phase of milling plant with VARIATION OF GRIST PARTICLE SIZE OBTAINED IN THE Bowl mill Similar to the vertical roller mill, it also uses tires to crush coal There are two types, a deep bowl mill, and a shallow bowl mill High speed Attrition mill The attrition mill is a device for mechanically reducing solid particle size by intense agitation of a slurry of material being milled and coarse milling mediaPulverizer Wikipedia

Feed Ops: Ingredient preparation World Grain

Roller mills are used where particle size control is needed Each set of rolls may be designed to crack, crimp, flake or grind products Fibrous grains and products do not process well in roller mills A set of rolls may be designed so that both rolls turn the same speed, which is a ratio of 1:1 of the roll speedsThe use of differential roll drive arrangements, which create a sheer effect between the chills, not only allows for a finer particle size output, but the sheering effect the roller mill has upon starch granules in cereals is advantageous to the nutritionist when compiling rationsHammermills versus roller mills Worldgrain WOLF Roller Mills A roller mill is a milling machine that gently and gradually reduces material to a smaller size The work done by the rolls on these particles will depend on the speed of the rolls, the differential speed or the difference in the speed of each roll, the type of flutes, the number of flutes, the amount of pressure holding Roller Mills Wolf EngineeringApr 19, 2018 Roll speed differential (approx 15:1) was set to create a shearing action and was 1,126 rpm for the fast roll (4064 cm diameter sheave) and 763 rpm for the slow roll (5994 cm diameter sheave) Hammermills reduce particle size by the impact of the grain against the moving hammer and forcing the particles through a screen with a specific Effect of roller mill configuration on growth performance rollers, roller diameter, speed and corrugation pattern Generally, roller mills grind grain into more uniformly sized particles than hammer mills (Figure 6) Figure 5 Roller mill Image courtesy CPM Roskamp Champion Roll pair Second roll pair Delivery device Figure 6 Difference in particle size distribution between a hammer mill and a FEED GRANULOMETRY AND THE IMPORTANCE OF FEED

MF2048 Hammermills and Roller Mills KSRE Bookstore

largesized and many smallsized particles Roller mills accomplish size reduction through a combination of forces and design features If the rolls rotate at the same speed, compression is the primary force used If the rolls rotate at different speeds, shearing Hammermills and Roller Mills Kim Koch Northern Crops Institute North Dakota State Nov 01, 2005 For example, compare roller mills with hammermills, or Fitzmills®, which grind by impact at high speeds and rely on a perforated sizing screen to control particle size Roller mills typically create 5075% less dust, or “fines”, and improve desired particle uniformity by 50100%Particle Reduction Technology For a ly Changing World WOLF Roller Mills A roller mill is a milling machine that gently and gradually reduces material to a smaller size The work done by the rolls on these particles will depend on the speed of the rolls, the differential speed or the difference in the speed of each roll, the type of flutes, the number of flutes, the amount of pressure holding Roller Mills Wolf EngineeringRoller mills can consist of a single, double, or triple pair of rolls that are stacked and enclosed in a steel frame (Figure 2) Figure 2 Illustration of a roller mill (Heiman, 2005) Feed passing between the rolls is sheared and compressed to reduce the particle size depending on the speed differential between the rolls The greater the GRAIN PROCESSING: PARTICLE SIZE REDUCTION Jul 19, 2018 This type of grinder produces a more consistent particle size with increased bulk The variable parameters of the Roller Mill are feed rate, quality of feed, and power to the Roller Mill and roll spacing The fixed parameters of the Roller Mill are roll corrugations (number per inch and profile), differential roll speeds and roll scrapersShould I choose a Roller Mill or Hammer Mill Grinder Mixer

Threeroll mill selection tips Processing Magazine

The material was expected to either sometimes slip on the top of the roller as speed increased or have problems transferring to the other roller With the settings provided and material used, the roller speed had a linear trend of a 1 rpm increase and caused a 0004 L/hour increaseThe particle size and its distribution should be continuously monitored and recorded Particle size is critical to quality factors (CTQ) to a pellet press Because it influences both feed quality (PDI) and productivity Specific Energy of Hammer mill; It is a measure of the actual productivity of grinding equipment, (Hammer mill or roller mill)Art of GrindingParticle size reduction Benison MediaRoller mills are used where particle size control is needed Each set of rolls may be designed to crack, crimp, flake or grind products Fibrous grains and products do not process well in roller mills A set of rolls may be designed so that both rolls turn the same speed, which is a ratio of 1:1 of the roll speedsFeed Ops: Ingredient preparation World GrainThe differential roll speed for the roller mill is no less than 16:1 as it was believed that any lower differential would not sufficiently grind the endosperm of the kernels Sieves are then used to separate the particles into respective germ and endosperm streamsUSB1 Corn milling process Google PatentsJun 01, 2018 In addition, milling variables (eg speed, sieve size, roller distance) and the energy used to operate the mill (Fang et al, 1997; Fang et al, 1998) are important Each mill has a limit to the size of particles it can produce based on principle forces (eg impact, compression, attrition) and on attributes (size, hardness, texture) of the Size distribution analysis of wheat, maize and soybeans

Hockmeyer Dispersers, Basket Mill, Wet Milling

Hockmeyer industrial dispersers, high viscosity high shear mixers, basket mill, wet milling grinding and tank washers Machines for particle size reduction