Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

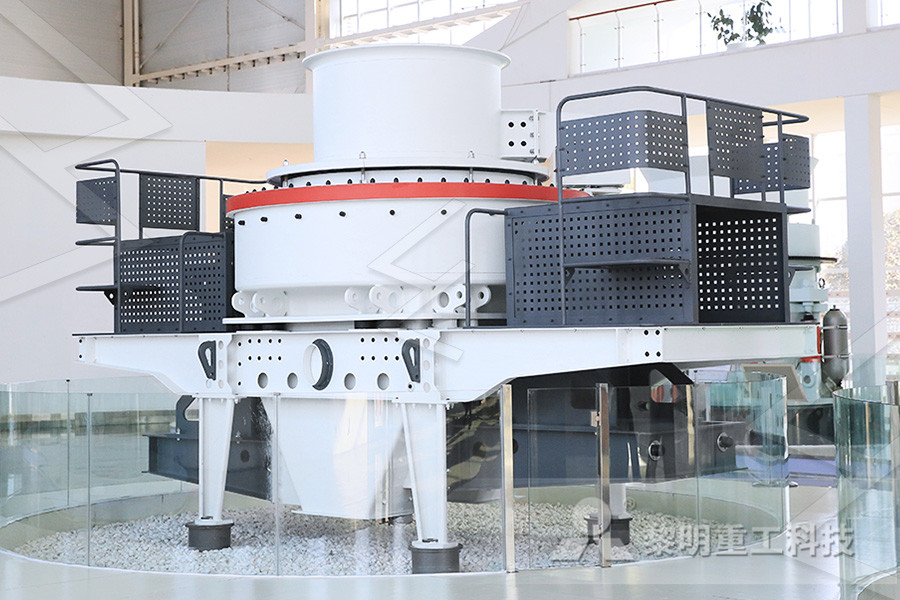

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

BASIC PRINCIPLE OF GRINDING Mechanical engineering

Process of grinding Grinding is the most common type of material cutting and surface generation process Mostly grinding process is used to shape and to provide better finishing parts of metals Grinding process uses one abrasive tool to make The working of a grinding machine: A grinder features an electric motor that supplies motion power to the grinding wheel using pulley and belt For the portable grinder, the rotor is inside the grinding machine and the power switch is located beside the handle of a grinder So, the switch must be pressed before the grinder worksWorking principle of a grinding machine studentlessonWorking principle of a grinding machine studentlesson 29/5/2020 Working principle of a grinding machine May 29, 2020 Material Science Leave a comment The working of a grinder or grinding machine is quite interesting, easy to learn and perform It is widely used in a different manufacturing company and it is available in different typesPrinciple And Working Of Grinding Machine MC WorldJul 28, 2020 Working Principle of Electrochemical Grinding In Electrochemical grinding, the metal bonded grinding wheel filled with a nonconductive abrasive The grinding wheel act as a cathode and the workpiece is act as an anodeElectrochemical Grinding: Working Principle, Advantages To grind a cylindrical part, the hydrostatic slide machine is the most suitable piece of equipment It can work with a variety of materials and modify delicate parts while preventing them from vibrating and breaking The part to be ground is placed between two points that will make it rotate on itselfWhat Are the Basic Principles of Cylindrical Grinding?

Grinding Machining Process : Complete Notes mech4study

Dec 23, 2018 In the grinding process, a layer of abrasive is responsible for removing the material from the work pieceWorking principle of a grinding machine May 29, 2020 Material Science Leave a comment The working of a grinder or grinding machine is quite interesting, easy to learn and perform It is widely used in a different manufacturing company and it is available in different types They are used for grinding workpieces at high surface quality, the Working principle of a grinding machine studentlessonWorking principle of a grinding machine studentlesson 29/5/2020 Working principle of a grinding machine May 29, 2020 Material Science Leave a comment The working of a grinder or grinding machine is quite interesting, easy to learn and perform It is widely used in a different manufacturing company and it is available in different typesPrinciple And Working Of Grinding Machine MC WorldGrinding forces depend on the balance of stresses, as the abrasive grains shear the workpiece material In metal cutting, there are three main zones of plastic shearing, all within the workpiece material The principle of minimum energy states that the stress arrangement that requires minimum total energy is Principles of Modern Grinding Technology ScienceDirectreamed, or bored hole, using small grinding wheels at high RPM The principle elements of a internal grinding machine are the workhead, which holds the work and has its own drive; and the wheelhead, which is the internal grinding spindle In addition to the rotary motions of work and wheel, an internalBasics of Grinding Manufacturing

Working principle of surface grinding machine

Working principle of surface grinding machine Surface grinding machine is mainly used for grinding surface workpiece The working principle of surface grinder is as follows: The main movement of the machine tool: the grinding wheel is directly driven by the motor mounted in the shell of the grinding head, which is the main movement of the The working principle of surface grinder is as follows The main movement of the machine tool the grinding wheel is directly driven by the motor mounted in the shell of the grinding head, which is the main movement of the Working Principle Of Hammer Grinding MachinesPrinciples of Modern Grinding Technology, Second Edition, provides insights into modern grinding technology based on the author’s 40 years of research and experience in the fieldIt provides a concise treatment of the principles involved and shows how grinding precision and quality of results can be improved and costs reducedPrinciples of Modern Grinding Technology: Rowe, W Brian Principles of Modern Grinding Technology, Second Edition, provides insights into modern grinding technology based on the author’s 40 years of research and experience in the field It provides a concise treatment of the principles involved and shows how grinding precision and quality of results can be improved and costs reducedPrinciples of Modern Grinding Technology ScienceDirectGrinding Machine: Types, Parts, Working Operations The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of working principle or rotating grinding equipment

Grinding SlideShare

Jul 07, 2015 WORKING PRINCIPLE 34 CENTERLESS GRINDING MACHINE 35 e Internal grinding machine In this type the grinding is done in the internal side of work piece In this operation the work piece may rotate or may not be rotate It can be done on different internal surface like straight, tapered, grooved, or profile 36The ‘grinding’ process is subject to principles similar to those known from other machining processes The ‘grinding tool’ is made up of abrasive grains and pores and exhibits an irregular distribution of cutting edges • Work piece speed v [mm/min] or [m/min]PRINCIPLES OF GRINDING DVSGruppeWorking Principle Grinding Machine ball mill working principleo be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body Working Principle Grinding Machine Dames DSVworking principle of grinding machine Working principle of Grinding Machine: Theworking principle ofagrinding machineis quite easier to understand In agrinding machine, there is an electric motor which supplies the motion power to thegrindingwheel with the help of working principle of grinding machine Machinery Sep 27, 2020 In this type of grinder, for holding the job on the chuck is used The job is moved through the medium of a grinding wheel and a regulating wheel There are four main parts of this grinder: (1) Grinding wheel (2) Work rest (3) Regulating wheel (4) Guide Their principle has been explained through the figure14 Types of Grinding Machines [Working, Diagram PDF]

PRINCIPLES OF GRINDING DVSGruppe

The ‘grinding’ process is subject to principles similar to those known from other machining processes The ‘grinding tool’ is made up of abrasive grains and pores and exhibits an irregular distribution of cutting edges • Work piece speed v [mm/min] or [m/min]Principles of Modern Grinding Technology, Second Edition, provides insights into modern grinding technology based on the author’s 40 years of research and experience in the fieldIt provides a concise treatment of the principles involved and shows how grinding precision and quality of results can be improved and costs reducedPrinciples of Modern Grinding Technology: Rowe, W Brian Dec 01, 2016 Multiple parts and part features can be ground simultaneously with infeed grinding, increasing throughput The Mikrosa workshop in Leipzig, Germany, where many models of centerless grinding machines are assembled and tested Form errors such as these can be reduced and nearly eliminated via sound knowledge of grinding principlesBasics of centerless grinding Cutting Tool EngineeringThe working principle of surface grinder is as follows The main movement of the machine tool the grinding wheel is directly driven by the motor mounted in the shell of the grinding head, which is the main movement of the Working Principle Of Hammer Grinding MachinesWorking Principle Grinding Machine ball mill working principleo be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body Working Principle Grinding Machine Dames DSV

working principle or rotating grinding equipment

Grinding Machine: Types, Parts, Working Operations The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm ( RPM, it may change according to the types of Sep 27, 2020 In this type of grinder, for holding the job on the chuck is used The job is moved through the medium of a grinding wheel and a regulating wheel There are four main parts of this grinder: (1) Grinding wheel (2) Work rest (3) Regulating wheel (4) Guide Their principle has been explained through the figure14 Types of Grinding Machines [Working, Diagram PDF]Sep 24, 2018 What is Electrochemical Grinding? It is a process that is quite similar to the electrochemical machining As per the name, it is the metal removal process which is nothing but the combination of the grinding process and electrochemical process What is Water Jet Machining – Working Principle, Advantages and Disadvantages with Application What is Electrochemical Grinding and How it Works grinding machine diagram with working principleGrinding Machine – Types, Operations performed (specially Surface Grinding, Get Price EME Syllabus diagrams Steam formation Types of steam, Steam properties specific , Steam Turbine Classification, Working principle and operation of Impulse andprinciple and working of GRINDING MACHINEprinciple of working of grinding machine working and principle of grinding machinemetal grinding in working principle May 12, The method is employed to machine hard and brittle materials which are either electrically conducting or nonconducting Analysis of the mechanism of material removal by USM process indicates that it may sometimes be called Ultrasonic Grinding USG Working Principle of Ultrasonic Machiningmetal grinding in working principle ME Mining Machinery

Mining Industry: What's the working principle of grinding

The working principle of grinding mill is that the grinding roller is rolled tightly on the grinding ring under the action of centrifugal force The shovel scoops the material to the middle of the grinding roller and the grinding ring The materiaworking principle of grinding machine worldcrushers Principles of clothes washing and washing machine design Using the countercurrent principle for rinsing, How working principle of a grinding machineCentre type grinding machines as the name itself suggests, a centre type machine requires that the work piece be supported at the centres while the operation of grinding is being performed There are several machines which can carry out centre type grinding and one such machine is the universal cylindrical grinding machineHow does Centerless Grinding Work ? Bright Hub EngineeringWorking Principles Of Grinding Machine Working principle of a grinding machine studentlesson the working of a grinding machine agrinder features an electric motor that supplies motion power to the grinding wheel using pulley and belt for the portable grinder the rotor is inside the grinding machine and the power switch is located beside the handle of a grinder so learn moreWorking Principle Of A Grinding Machine